Highlights

Highlights

Benefits

- Low mass and power density solutions for reduced engine room size

- Ultra-low noise and vibration characteristics

- Hybrid gears and special consideration to integration of complex shaft-line and control

Features

- Integrated propulsion thrust bearings, clutches, brakes, turning gear and shaft locks, oil systems, and control units

- Through-hardened, nitrided or carburised, ground gears with high degrees of accuracy and ultra-light weight construction

- Heavy-duty or light-weight designs to provide a solution that will last the life of your vessel

Capabilities

- Providing transmission from a full range of prime movers to a variety of propulsion solutions

- Input speeds from 500 to 17,000 rpm, reductions from 2:1 to 15:1, transmission from 1 to 40 MW

- Military and commercial: fast patrol, corvette, hovercraft, destroyer, tug, dredging, fishing, cargo, cruise, and ferry

Overview

Overview

Lufkin Gears and Allen Gears are known for reliability around the world. We have over 80 years of engineering expertise, innovation, and support in turbomachinery—with over 3,300 customized marine propulsion gears supplied to navies and commercial operators worldwide.

Rugged. Robust. Reliable.

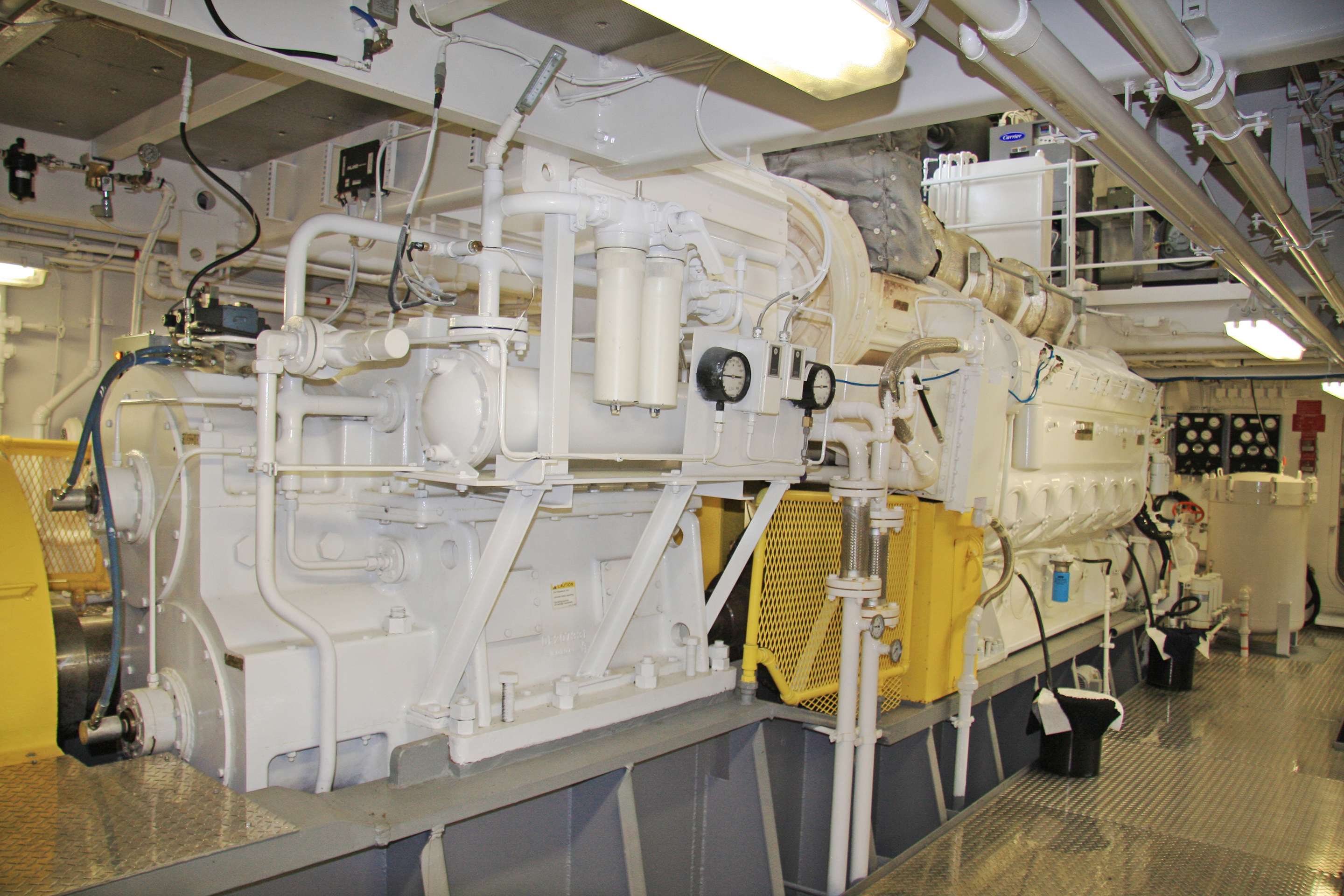

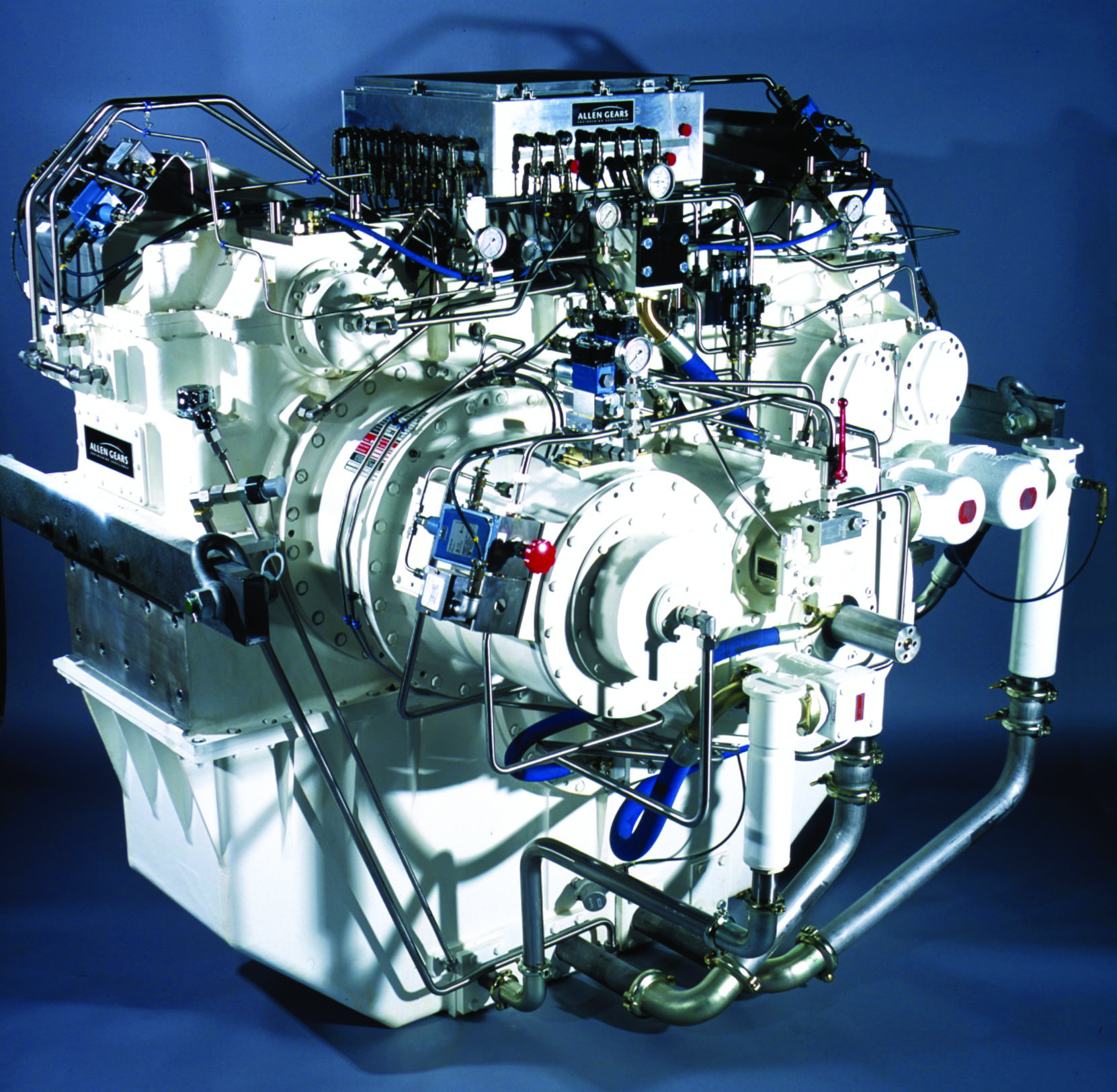

The marine industry demands reliable performance, extreme power, and exceptional mechanical integrity from a propulsion system. Allen Gears and Lufkin Gears, Baker Hughes businesses, specialize in the design and manufacture of high-quality marine gearing, providing customers with the most cost-effective, dependable, and timely solutions for critical propulsion applications.

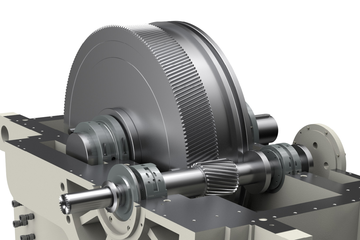

We've been driving the marine industry since 1942—with custom-engineered, high-performance, epicyclic and parallel shaft, high- and low-speed gearboxes and services. Our experience and vigorous professional training program mean your vessel can benefit from deep technical knowledge, technology-driven solutions, and world-class engineering practices. We use the highest quality materials and processes such as carburizing, CBN gear-tooth finishing, as well as unsurpassed quality control to push industry standards higher and your business farther.

Our installed base covers all blue water (sea) and brown water (inland river) work boats and tugs, ferry boats, cruises, fishing vessels, dredges, cargo vessels, hovercraft, patrol vessels, fast attack ships, military vessels, offshore vessels, super yachts, and pleasure craft. Allen Gears and Lufkin Gears marine products are designed and rated in accordance with a variety of international shipping standards, including: AGMA, ABS, MIL, ISO, Lloyds, DNV, Germanischer Lloyd, and RINA.

Allen Gears and Lufkin Gears marine gears can be supplied complete with oil systems and control elements. We provide mechanical and electrical pumps, oil conditioning equipment (pressure, filtration, cooling), starter boxes, and control and monitoring modules to provide manual local or remote automatic control and feedback.

Low- and medium-speed marine

Whether you're repowering an existing vessel or building new, Lufkin Gears marine gears are well suited for 500-1,500 rpm engine speeds. Catalogue units with ratios ranging from 3:1 to 8:1 are available for easy project design. Custom designs are also available to meet any specific project needs.

Lufkin Gears has installation references with all major makes and models of low- and medium-speed diesel applications. You can leverage our extensive marine experience of reverse reduction marine propulsion gears to ensure unmatched reliability and performance. Allen Gears has low and medium-speed military marine installation references including Coast Survey, minesweeping, Multi-role.

High power, light weight

Allen Gears marine gears are purpose-built to exacting customer specifications. Whether performing in large ships or small, fast vessels; driven by gas turbine, medium/high-speed diesel engine, or a combination of both—our gears are well suited for prime mover speeds from 1,000 to 17,000 rpm. We have proven experience with powers from 2 to 40 MW and reduction ratios up to 15:1.

Allen Gears tackles complex configurations requiring specialized engineering skills, using lightweight construction and precision machining techniques to provide solutions for fast military vessels such as:

- Littoral mono-hull patrol craft

- Small frigates

- Surface effect catamaran

- Super yachts

- Hovercraft

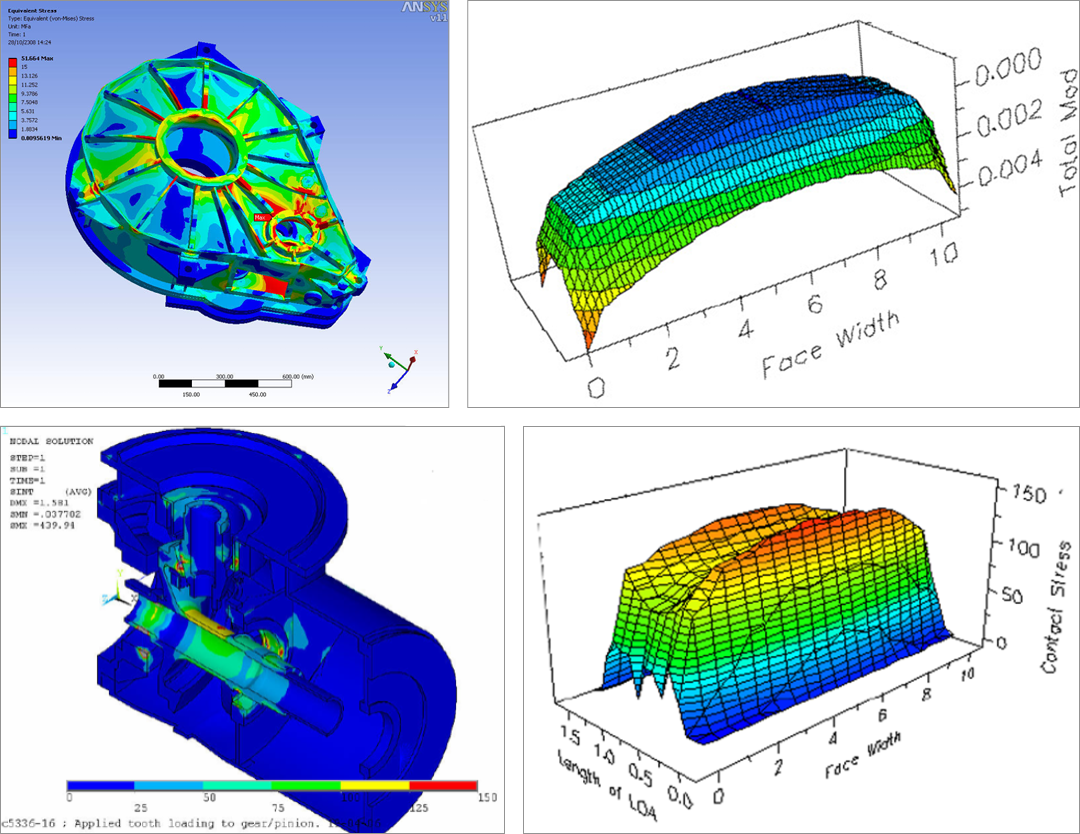

Special consideration is given to the design and manufacturing of all components to maximize weight reduction, reduce noise generation, improve durability, and increase life—to make a product that exceeds customer expectations. We address every aspect: casing, shafting, gear teeth, bearings, mounting, oil system, system integration, dynamic response. And we employ specialized analysis tools to assess deflection, longitudinal and torsional vibration, transmission error, and efficiency.

Meeting all application demands

Luxury yacht

Naval

Patrol

Combatants

- Very light weight

- Low resulting air borne cabin noise

- Mild cyclic shock loading (fatigue)

- Low structural borne noise

- High level of functionality

- Space envelope restrictions

- Very light weight

- Moderate shock (fatigue and ultimate strength)

- Flexibly mounted systems

- Light weight

- High shock survivability (ultimate strength)

Allen Gears has installation references with major makes and models of gas turbine and high-speed diesel engines. Our extensive experience in power-transmission gears ensures unmatched reliability and performance in providing transmission from a full range of prime movers (gas turbine, steam turbine, diesel engine, and electric motor) to a variety of propulsors (controllable-pitch propellers, fixed-pitch propellers, and water jets or generators).

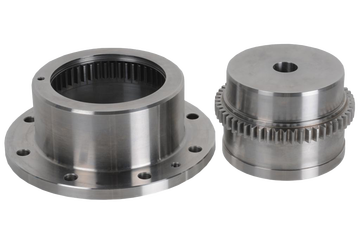

Allen Gears marine propulsion solutions include parallel, epicyclic or bevel gears, ranging from single-in/single-out (SISO) to multiple in/out including power take-in/power take-off (PTI/PTO) for hybrid electric drive or ship ancillaries such as oil pumps for water jet or controllable pitch propeller control. Our portfolio ranges from single-stage, parallel-shaft to multi-stage combinations of epicyclic and parallel shaft, in vertical, horizontal, and angled offsets. We provide CODOG, CODAG, CODOD, CODAD, CODELOG and CODELAG configurations including cross connection.

Allen Gears also manufactures marine generator drives. Our famous epicyclic generator drive solutions are packaged to suit the high-power light weight marine environment.

Hybrid gears

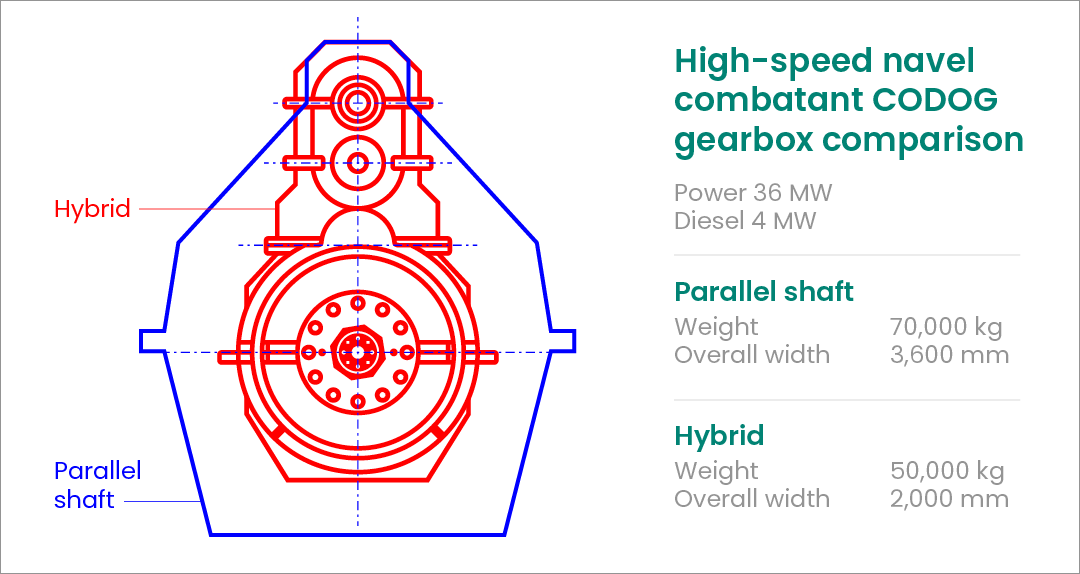

Parallel-shaft is currently the predominant arrangement used in the marine industry. Combining epicyclic and parallel-shaft gears with the epicyclic gear as either primary or final reduction enables significant weight and space reductions, while improving efficiency.

Epicyclic primary reduction

Epicyclic final reduction

- Eliminates high-speed bearings

- High ratio reduction in small space envelope

- Improved efficiency

- Reduced oil flow requirements

- Lighter-weight package

- High toque split across multiple meshes (minimum 4)

- Planetary configuration gives high ratio

- Eliminates large final bull-wheel

- Reduced overall width

- Significantly reduced weight

Custom drop-in applications

The most robust gears in the industry are available as drop-in replacements for your existing architecture! Contact us for any repower, overhaul, or replacement projects of any existing propulsion systems. We offer critical service, high performance gears to match existing mounting provisions and hull dimensions rated for full power and speed of new generation engines. Available to meet international rating and resign codes such as ABS, ICE class, USCG Subchapter M, and many other regulations.

Design services

Allen Gears and Lufkin Gears tackle complex configurations requiring specialist engineering skills, including:

- 3D contact stress analysis

- Optimized tooth profile

- Integrated housing-mesh alignment assessment

- Variable loading conditions evaluation

- Application of finite element analysis techniques

- Linear and non-linear evaluation techniques

- Structural dynamic and fatigue analysis

- Lateral and torsional rotor dynamic analysis

- Damped and response analysis

- Verified rotor response test bed measurements

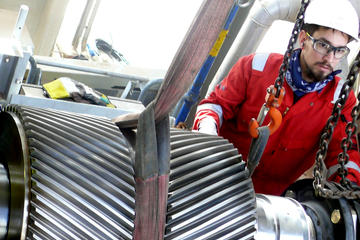

Field services

Allen Gears and Lufkin Gears field service specialists will support you throughout installation and commissioning—including harbour acceptance and sea acceptance testing—and throughout the life of the vessel.