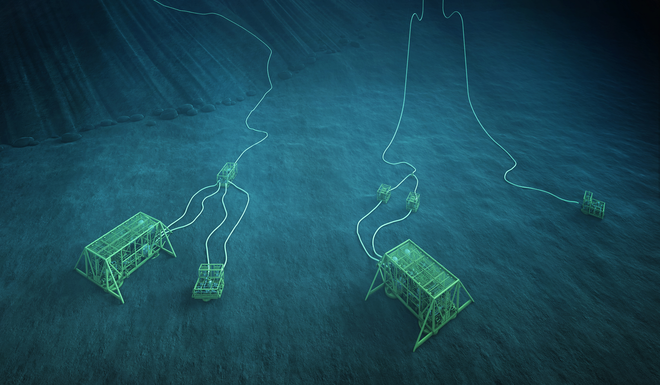

Subsea optimization starts here

Subsea operations are very complex, interlinked and involves a variety of factors: from environmental conditions, equipment reliability, to personnel safety. These operations also involve a multitude of processes, from engineering, equipment manufacturing and maintenance, as well as offshore and onshore activities.

engageSubsea is a modular platform that can be deployed at any stage of the field life to simplify and optimize subsea activities, unlocking new levels of operating efficiency and cost savings.

Benefits

Digital Connectivity

- Live inventory overview with tracking of past, present and future maintenance and events

- Real-time orders management and updates

- Digital access to documentation and equipment history

- Instant troubleshooting during any stage of a field’s life cycle

- Trend diagnostics, event prediction, and recommendations for intervention and maintenance

Visibility

- Instantaneous data access for all subsea activities

- Digital inventory of all managed equipment

- Advice from flow-assurance specialists on flow regularity and production optimization

- Support for comprehensive monitoring of facility integrity and performance

Operational Excellence

- Proactive asset management

- Spares optimization with up to 50% reduction in inventory

- Preventative maintenance forecast

- Obsolescence alerting with upgrades and follow up

engageSubsea is the digital source of truth connecting customers across the life of field, consolidating multiple data streams and allowing end-to-end operational visibility and analytics.

Subsea Insights Dashboard

Experience the power of a comprehensive and intuitive system that allows you to effortlessly comprehend every aspect of your subsea assets. Gain a real-time, 360-degree view of your installed equipment, preventative maintenance forecasts and critical alarms. Our tailored and simplified traffic light system directs your attention to what truly matters for faster and better-informed decisions than ever before.

Installed base

Optimize your operation and increase it visibility with a live digital inventory tool. Whether XT, Chokes, Manifolds, Electronics or Controls, all your major equipment and their respective specifications such as Max pressure, serial number, minimum temperature, bore size, etc) are accessible in one, easy to navigate platform including documentation such as 3D models, 2D drawings and MRBs.

Operation Excellence

Get a full and live status update of all offshore activity – past, present or forecasted, with specific details around progress, tooling, spares, personnel including the end of well report.

Managed Equipment & Preventative Maintenance

Visualize a live digital inventory of managed equipment, tooling including it maintenance history. It also showcases forecasted scheduling and any defects of tools and provisional hazards, further simplifying the decision-making process.

Obsolescence Management

Proactively resolve obsolescence issues at an early stage to ensure that equipment problems do not accumulate into large-scale high-cost challenges. This feature provides unbiased, agnostic advisory for equipment and systems upgrades.

Asset Health Score

Prolong operable life and optimize productivity with an objective view of the overall health of operator assets, fields and infrastructure.

Passive Well Monitoring

Rest assured about the integrity or your wells by using the passive and continuous monitoring application. This agnostic system collects and detects specific gas and/or fluid leaks to alert on its location and triggers pre-determined response workflows.

24/7 Remote Operation Support Center

Rise queries for around the clock field technical and operational support services. The queries are managed through our 24/7 center manned by subject matter experts first responders, using best in class augmented reality video assistance tool to optimize field operations.

Robotics Inspection & Cleaning Services

Access, view and leverage data obtained from autonomous robots during inspection, cleaning and maintenance operations of subsea (unmanned) structures.

Lifecycle management

Passive Management

Field twin

- Digitally visualize the subsea installed base

- Reduce OPEX through improved operations and maintenance planning

- Asset Performance benchmarking

- Aid planning toolkit & 3D Viz

Active Management

Life job and process tracking

- Track projects and services in real time

- Improve speed and coordination

- Operational readiness and forecasting

- Ensure compliance to standards and processes

Proactive Management

Analysis, scoring and advisory

- Asset health analysis, scoring and advisory services

- Engineering and asset performance optimization

- 24/7 proactive monitoring and support

- Live customer care portal

- 24/7 monitoring and advice

- Remote technical assistance and troubleshooting

- Unmanned operations and robotics