Highlights

Highlights

Benefits

- Extend maintenance intervals, reduce operating costs, and increase unit life

- Enhance efficiency and plant output, and simplify equipment operation with unmanned solutions

- Reduce greenhouse emissions, and introduce new energy solutions

Features

- Brownfield executional excellence to minimize plant impact and turnaround time

- Advanced materials and component designs that improve stress and temperature resistance as well as performance efficiency

- Full capabilities from component replacement to upgrade or replacement of aging units, and related balance of plant requirements

Applications

- Gas and steam turbines, electric motors, generators

- Centrifugal, axial, and reciprocating compressors

- Expanders, pumps, auxiliaries, control systems, balance of plant

Featured Video

Featured Video

Overview

Overview

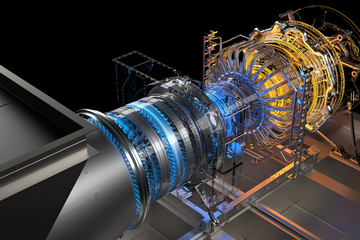

Technologies, engineering capabilities, and regulatory requirements evolve all the time—and there are many ways to bring the performance of aged turbomachinery more in line with current standards.

Our experienced personnel continually develop and integrate new technologies that increase equipment productivity in the most economical ways. The result is a wide range of conversion, modification and upgrade (CMU) solutions that improve the availability, reliability, emissions, productivity, and lifecycle costs of our customers' installed equipment.

We've successfully executed over 1,500 CMU projects around the globe. Working closely with customers, our engineers have developed solutions to optimize the production of upstream sites, produce more LNG, transport more gas through pipelines, increase the output of refineries and petrochemical plants, and much more. With short payback cycles, our proven CMU solutions are the most effective ways to improve the value of your assets.

As the original equipment manufacturer (OEM), we have the best knowledge and experience to assess the feasibility of various options that could be applied to your equipment; and our dedicated engineering team is at your disposal to help identify the best choice.

Below are just a few examples of the many CMUs we offer.

How to get more from your aeroderivative gas turbines

DLE 1.5 upgrade to reduce emissions for LM2500 and LM2500+ turbines

Advanced combustion technology from our LM2500+G4 engine (including upgraded design, materials, coatings, and enhanced cooling) is integrated into the installed LM2500 base engine or LM2500+ turbine (SAC and DLE 1.0 versions of both). It reduces NOx emission from 25 ppm to 15 ppm, and CO2 to 25 ppm—and can be extended in some cases down to single-digit emissions. Automapping is also available for several engine models.

PGT25+G4 airfoil upgrade for better performance in hot and cold ambient conditions

Engines are typically designed for best performance at ISO conditions, but many installed units actually operate at hotter or cooler ambient conditions. Changing airfoil profile makes it possible to optimize performance at a specific ambient temperature. Our engineers can study your operating conditions to identify the improvement potential, and then we can redesign and produce low-pressure turbine (LPT) airfoils to obtain new tent curves.

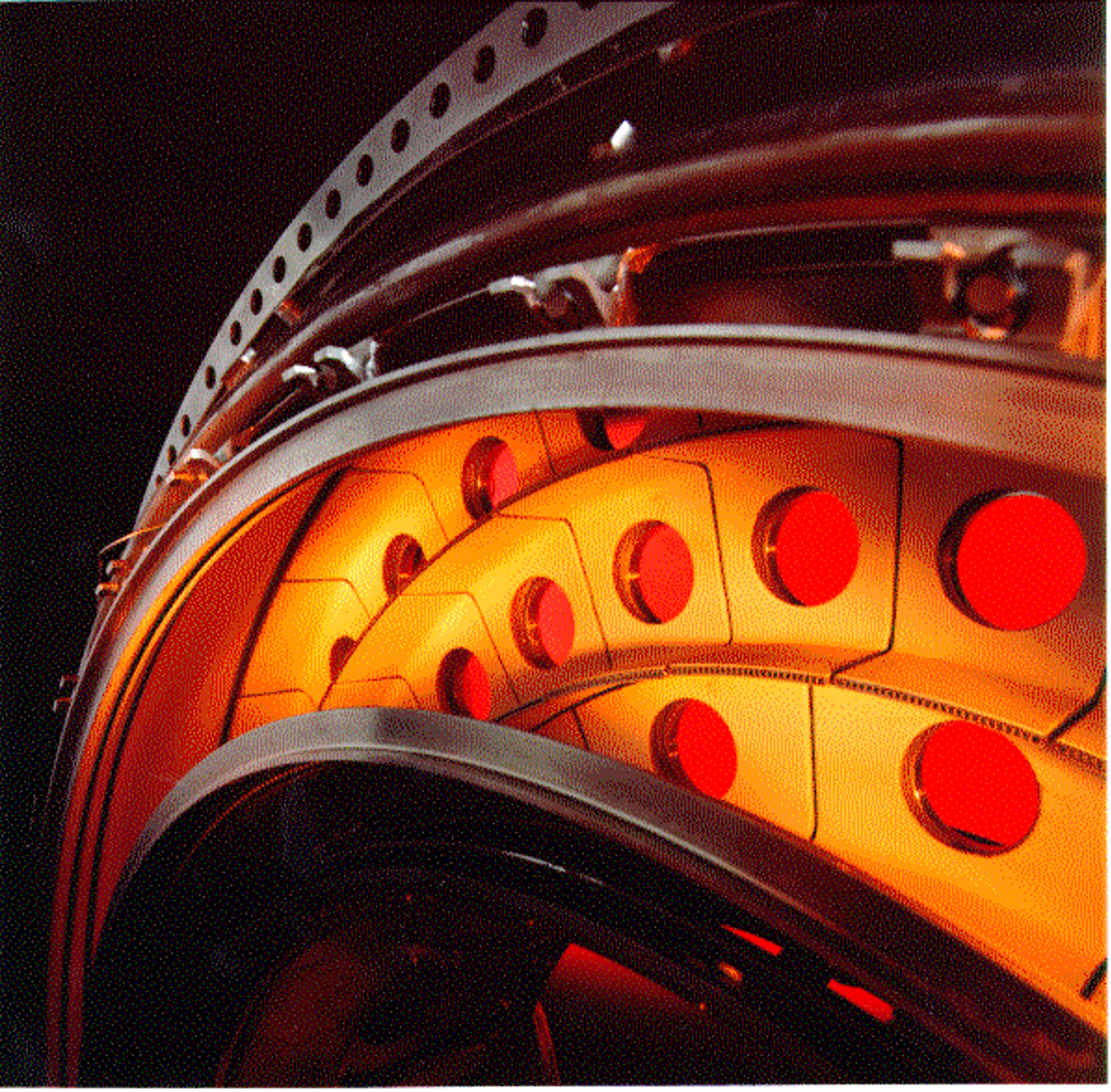

Hot section maintenance extension upgrade for LM2500 and LM2500+

We utilize advanced hot section technology from the LM2500+G4 for an installed LM2500 base engine or LM2500+ (SAC, DLE 1.0 and DLE 1.5 versions). It includes upgraded materials for high stress and temperature resistance, coatings, and enhanced secondary cooling, as well as innovative new digital control features. This solution extends maintenance intervals for the hot section from 25K hours of duty up to 50K hours, reduces operating costs, and increases unit life.

How to get more from your steam turbines

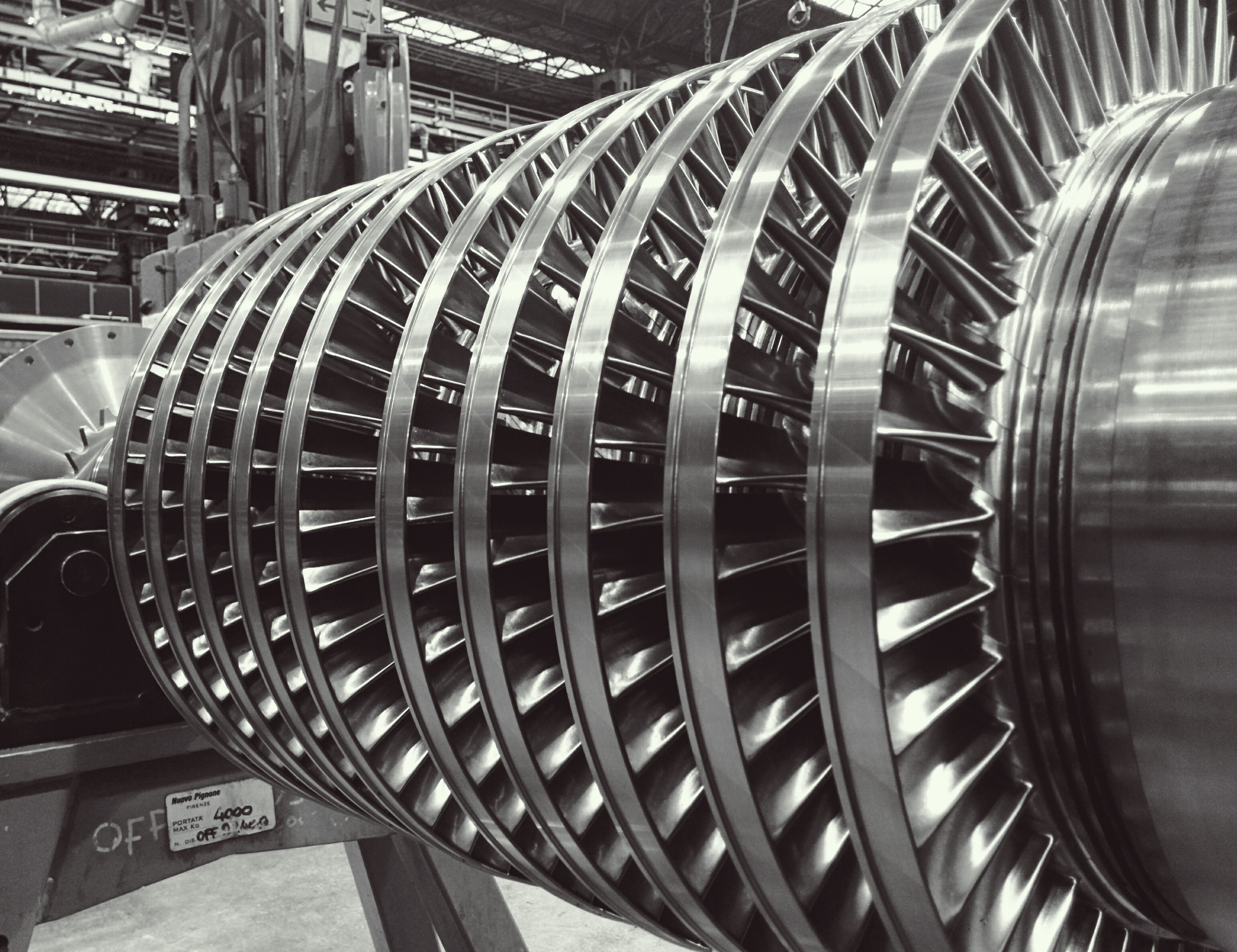

High-efficiency stages

We can replace the 2nd and 3rd stage blades of your reaction turbine with newly designed blades with improve aerodynamics. Case studies show an efficiency increase of about 2% overall, and above 2.3% for the single drum.

Sealing technology replacement (efficiency and intrinsic safety)

Our latest back-spring seals can be installed with shorter maintenance time, since replacement is done on the blade-carrier with a faster re-assembly procedure. No additional machining is needed, and the rotor and blade-carrier lower half do not need to be removed.

Our abradable seals improve turbine maintainability versus traditional strips seal labyrinth seals, and you can expect 0.4% to 1% lower steam consumption.

Comparted to J-strips, our brush seals reduce leakage on balancing or recovery drums. They deliver an efficiency increase of 1-2 points, depending operating conditions.

Valve actuator electrification (reliability, simplification and connectivity)

We provide both electro-hydraulic and electro-hydrostatic valve controls.

The hydraulic option features:

- Precise position control and fast response time

- Redundant Linear Variable Differential transformer (LVDT) position sensors

- High tolerance to contaminants, operates on oil filtered to 24–40 microns

- Limited hardware modifications and no manual site calibration

Advantages of the hydrostatic option include:

- Simplified package

- Reduced weight and footprint

- Plug-and-play—no separate items for field assembly or installation

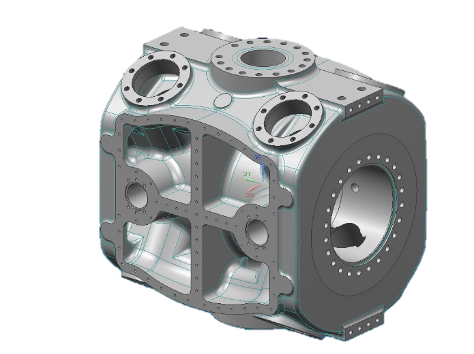

How to get more from centrifugal compressors

High-efficiency stage technology

Development of the core impeller is the key to improving performance. Our impellers portfolio covers all service requirements, and is continually evolved and updated based on extensive analysis of data from tests and our global installed base. The results are exceptional performance and predictability.

Thermoplastic labyrinth seals to improve efficiency

Common metallic seals are designed with large clearance to avoid contact with rotating elements during operation. Some metallic materials are generally subjected to degradation due to corrosion interaction with gas contaminations, such as chlorides, mercury, and acidic environments.

Our retrofittable labyrinth seal system has reduced clearance thanks to an innovative material that guarantees a better response in case of transient or prolonged contact of the two surfaces. The system can be made from reinforced PEEK, PEK, PAI or VESPEL CR-6120. It delivers a proven polytropic efficiency increase, and is compatible with harsh environments.

Abradable seals

Some metallic materials degrade due to corrosion interaction with gas contaminations such as chlorides, mercury, and acidic environments.

We therefore offer a teeth-on-rotor (TOR) design with statoric seal in abradable material compatible with extreme ambient conditions. : Al-based METCO601 thick coating is compatible with all environments except mercury, and has no temperature limitations. MICA-filled PTFE (e.g. Fluorosint 500®) is compatible with harsh environments including sour and acid gas, mercury, and chlorides. Our design also minimizes gap leakages, and delivers proven polytropic efficiency increases.

How to get more from reciprocating compressors

High-efficiency cylinder valves

Our latest cylinder valves have rings shaped to reduce gas pressure losses, and more rings with increased geometric flow area. There are smoother gas passages in the valve seat and guard, lower impact velocities and lower alternate stresses on springs, and new spring caps that avoid contact

between spring coils and valve guards. This design enables efficiency up to 40%, 3x longer part life, and improved reliability.

New internal parts kit for cylinder

The kit includes new cylinder head, spacer and valve cages. Features include:

- Improved shape of suction and discharge flow paths

- Reduced dynamic pressure losses

- Improved compressor efficiency

New cylinder technology

Our new cylinder design has optimized efficiency on process gas path. Modified shape of cylinder head and liner spacer creates smooth passages from valve to bore. Optimized water jackets reduce water flow and increase cooling efficiency, and we've used nodular cast iron (NCI) instead of cast steel (CS) material. We also optimized the casting process with co-design assistance from some of the best and most trusted foundries. These enhancements combine to deliver higher compressor efficiency.