When stuck-pipe problems occur, you need to resolve the situation quickly. Baker Hughes has the technology, tools, and expertise to solve specific stuck-pipe problems safely and more economically.

Pipe recovery operations generally occur in three stages:

- Free-point depth determination

- Pipe separation

- Fishing the remaining stuck pipe

First, our pipe recovery specialists will determine the root cause of the stuck pipe through a thorough analysis of the well configuration and events leading to the problem. We choose the proper tools and services to efficiently execute recovery operations.

Next, the pipe string is worked sufficiently to determine the free point and is backed off or cut to remove the free portion from the well. After retrieving the free pipe, the well can be reentered to jar loose or wash over the remaining stuck pipe. In certain drilling operations, the remaining stuck pipe may be sidetracked for economic reasons.

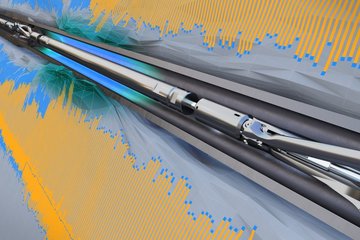

Our capabilities include several fit-for-purpose free-point indicator systems. Diagnostics logging determines a strategy or cause, consisting of the pipe-recovery log, noise, temperature, and other measurement services. We offer a wide variety of proven technology to cut or separate the free pipe from the downhole tubulars.

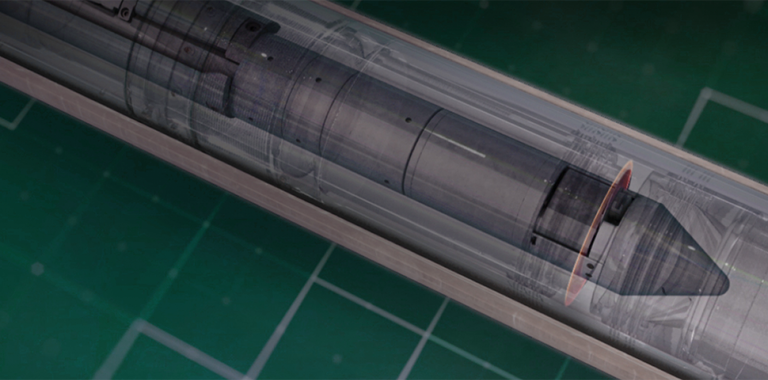

These cutting services consist of back-off, chemical cutters, jet cutters, metal-severing tools, split-shot cutters, and the new Mechanical Pipe Cutter (MPC™). The MPC reduces logistical and environmental constraints, delivering precise downhole pipe cutting without ballistics or hazardous chemicals, and reduces nonproductive time (NPT), risk, and intervention costs.

Contact your local Baker Hughes representative to find out more about our fast and efficient pipe recovery solutions.