Overview

Challenges

- Flame intensity in customer's DLN1 turbines was too low for detection by standard UV sensors

- Turbines couldn't complete transition to premix for successful start-up

Results

- Existing FTD 325 sensors re-engineered to improve sensitivity to smaller UV signals

- Customer easily transitioned from lean-lean to premix combustion without interruption—enabling successful start-up of both units

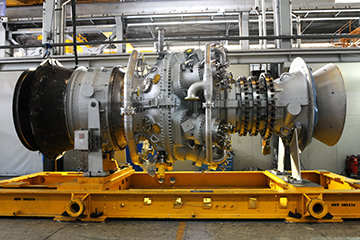

Every gas turbine exhaust produces NOx emissions, but a turbine with DLN1 combustion uses a fuel-lean ratio to minimize NOx. That requires precise premixing of fuel and air before ignition.

Unfortunately, standard flame sensors don't have the extreme UV sensitivity needed to help manage that precise process, so the turbines aren't able to successfully complete start-up.

Our Reuter-Stokes team created a new version of the FTD 325 specifically for this application. We installed the first four of these new increased-low-gain (ILG) sensors on two DLN1 Frame 5 turbines at a customer's LNG facility. They enabled easy transition from lean-lean to premix combustion without interruption—and successful start-up of both units.

Get the full story in PDF