Rami Qasem recalls growing up “next to the oil and gas industry” in Saudi Arabia, where his father and many of his extended family worked for the petroleum and natural gas giant Saudi Aramco. Although young Rami’s first choice was to study medicine, his passion for problem solving quickly drew him into an electrical and electronics engineering degree undertaken in that other great oil state — Texas. And because, “Everything potentially has to do with the energy sector,” he says, “that’s where I am today.”

The now Executive Vice President of Baker Hughes’ Digital Solutions business says, “I’m immensely proud to be celebrating a little over a year of our relaunch as an energy technology company.”

Since Qasem began working with industry-leading asset protection and conditioning monitoring company Bently Nevada in the 1990s, he has engineered or been party to many changes, mergers and acquisitions in the energy services sector. Bently Nevada was acquired by GE in 2002, and has now become a Baker Hughes company, and one of a complementary group of specialized digital technology providers that underscores Qasem’s all-roads-lead-to-energy point.

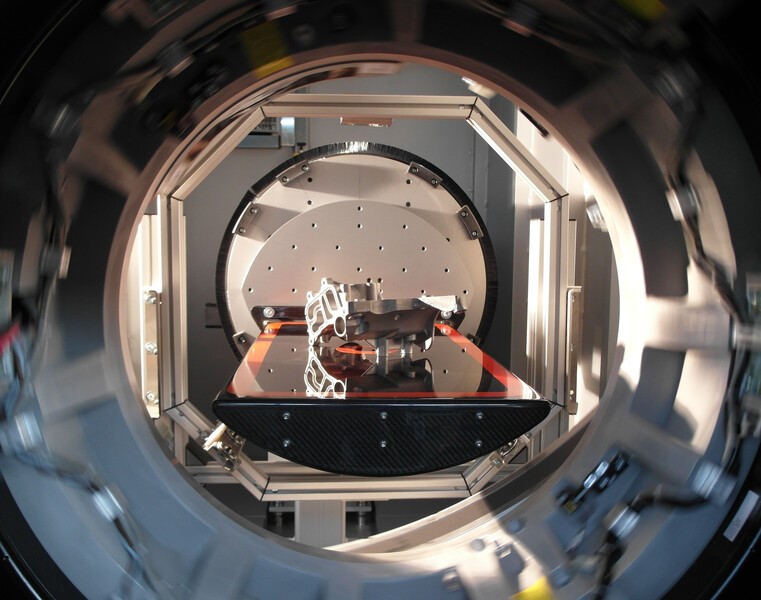

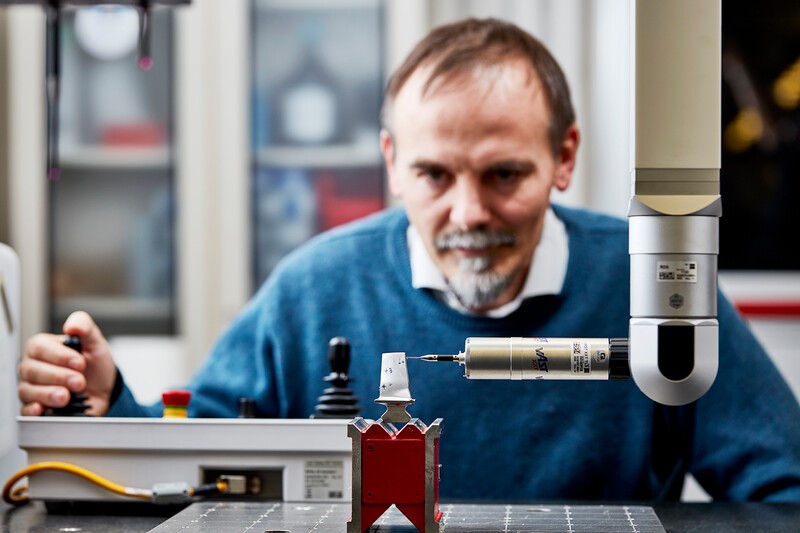

Another part of the portfolio he now oversees, draws on computed tomography (CT) scanning innovations and portable ultrasound technologies originally developed for medical applications, to test the reliability of parts used in all fields of energy production — from oils to renewables — as well as components critical to the safe operations of aerospace, automotive and infrastructure projects. One of these technologies was even used earlier this year to help with the COVID response.

Working on a range of cutting-edge “sensors, control systems and software”, says Qasem, “gives us the ability to collaborate with companies outside our core verticals; to go beyond the oil and gas industry and lead our organization’s transformation into an energy technology company”.

Go Forward!

Industries across the world are experiencing the most disrupted of times, and Qasem says this requires engineering project teams to “double down on efforts in developing disruptive technology” to meet these challenges with radically effective solutions. “Technology is in our DNA. And I believe innovation thrives through collaboration. Industrial customers rely on us to help them move faster” he says, to get ahead of trends in the Fourth Industrial Revolution (4IR), which is characterized by a fusion of advances in the digital, physical and biological worlds. “I mention collaboration as a means to accelerate disruptive technologies through an innovation network of partners- be it from industry, academia, research and other,’’ he adds.

The energy industry has already made huge strides in adapting to COVID-19 conditions by embracing remote operations — such as remote performance monitoring and troubleshooting, remote plant start up and the highly digitized application of remote drilling. “Today,” says Qasem, “everybody wants to continue operating with less physical movement of people, driven by the pandemic.” Investments in capabilities such as virtual collaboration, and offsite virtual training are enabling onsite efficiency. Qasem says, “The adoption of these technologies is a great thing for the technology, as it enables a continuous shift into remote operation.” The use of drones and artificial intelligence for methane leak detection is another example of how technology is being deployed to reduce the need for humans to travel to industry assets and sites.

Like the energy sector, aviation has been becalmed by the pandemic. In this environment, Qasem says it is paramount to become far more than a leading supplier of advanced equipment — “Today you have to be a solution partner for your customers to succeed.” Despite what he sees as a temporary downturn in aviation and aerospace more broadly, Rami insists that many companies still want to invest and are looking into how they can commercialize space travel, for example. Working in tandem with its aerospace customers, unique companies like Baker Hughes are leveraging advanced oil and gas technologies to ensure that those who are shooting for the moon have the most reliable and efficiently engineered components. A recent example is the partnership announced for additive manufacturing services with Wurth Industry North America.

Additive manufacturing capabilities respond to the need for speed of development. Non-destructive testing validates the reliability of new components, as well as monitoring for wear in parts already in service and thereby allowing timely replacements and reduced downtime.

Cybersecurity can be built into remote monitoring and operations using sophisticated software, to safeguard assets from cyber threats. ‘’We are truly transforming our Digital Solutions business as the foundation to build a 4IR enterprise capability.’’ Qasem reflects.

A critical mass of R&D

Faster design and deployment will go hand in hand with lower development cost and repeatable solutions. Qasem describes his engineering team as ready to ‘’anticipate improved user experience for our customers, due to the iterative and feedback-based nature of the design process." He says, "Some of our legacy brands have been innovating for more than 120 years — spanning the previous industrial revolutions — and draw on a rich history for future development.” He adds that, “the right integration and embedding everybody in the same culture is key to advancing our customers’ ambitions”.

He observes that COVID-19 has given all business leaders pause to assess what they have and how their operations can become more efficient in order to pursue new opportunities. “I believe we are working in the right environment to drive the transformation of the sectors we serve,” says Qasem. “Just as a commitment to lower carbon emissions is now the norm, radical disruption is becoming the prevailing state. There is a clear need for energy industries and the entire industrial sector to perform more reliably, efficiently and digitally than we have ever seen before. The Fourth Industrial Revolution is our reality.”

For additional reading from Rami Qasem on the 4th Industrial Revolution, click here.

Energy Forward Stories

Sign up to stay up to date on the latest innovations and people shaping the future of our industry.