Claudia Penarrieta’s most potent message to the energy industry is to “think ahead”. The virtually globetrotting Technical Lead for Condition Monitoring in Machinery Diagnostics Services at Bently Nevada, a Baker Hughes business, is referring to embracing digitalization, accelerating access to operational insights, and improving decision making in the new era of remote operations.

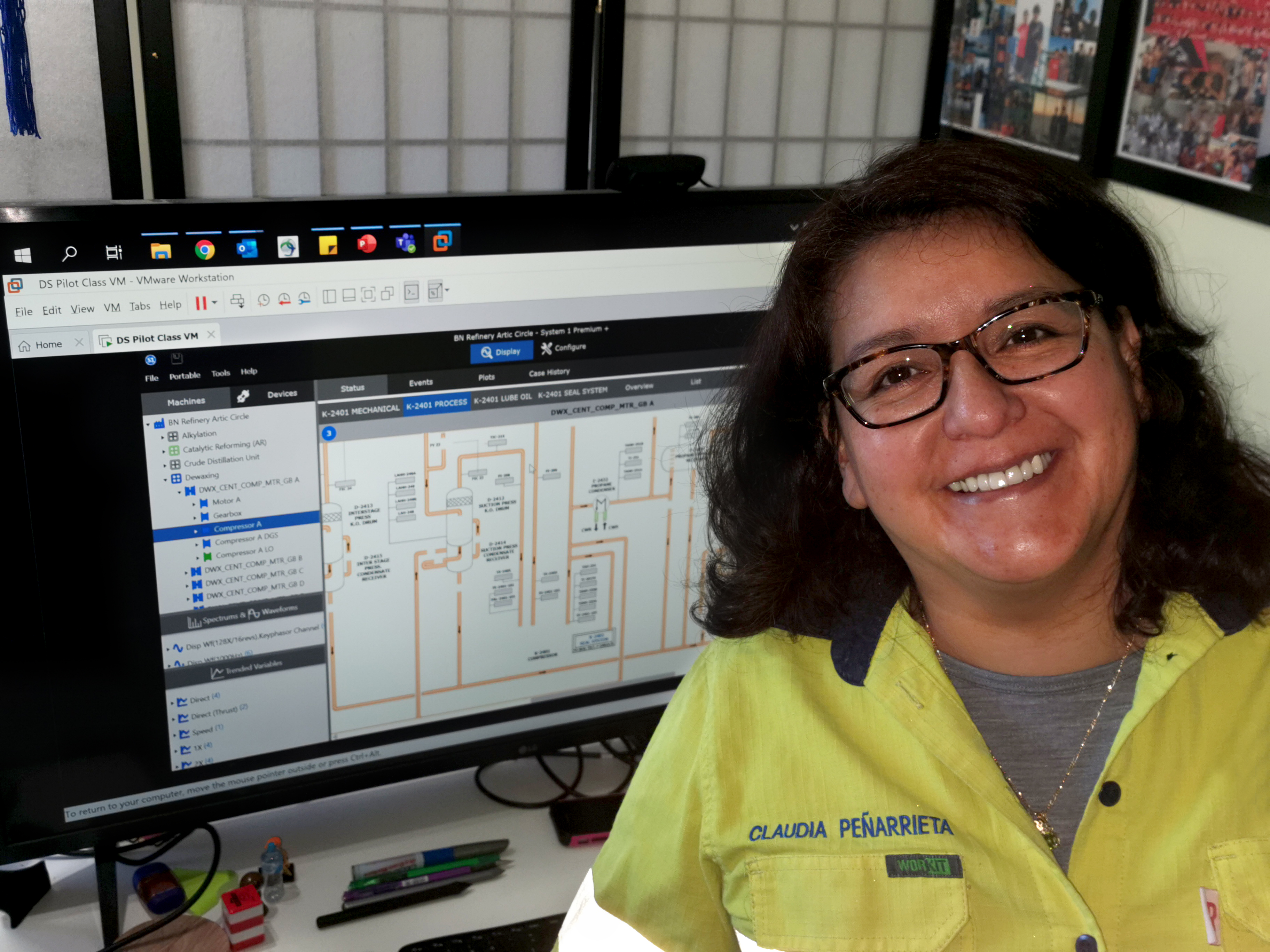

She models her own advice. On the one hand, she disseminates her knowledge of Bently Nevada software systems — which turn data from strategically deployed proximity probes into actionable information — to teams of service engineers to help them ramp up reliability of machinery on customer drilling and processing sites. From her home in Brisbane, Australia, she is on call day and night to support the efforts of Baker Hughes’ teams in the Asia-Pacific, China and South American regions. “I love troubleshooting and solving problems,” she says.

Then there’s her day job: Claudia leads education and integration sessions with teams who may be deploying, upgrading or tailoring sales pitches for condition-monitoring systems to customer needs. “This Friday” she says, “I have a meeting with two service engineers who are going to one of our customers in Malaysia to install a bunch of logical rules that we developed with another, Slovakia-based, engineer.”

At the same time, she’s also getting ahead of the software game, working with a global team to develop an extension of the System 1 condition monitoring platform that will use machine learning to aggregate performance information, and detect patterns of failure or malfunction across vast systems of equipment, enabling the next level in operational understanding and reliability.

“I think, as humans, we often look at a single problem, we fix it and we move on,” says Claudia on the importance of the new software. “We don’t step back and ask why something hasn’t been working, or whether this is the first time we’ve seen this problem or make a connection to other equipment failures on a site.” These are relationships that machine learning, given the right information, can readily identify, and Claudia is helping formulate the basic logic, the rules that set the conditions for investigation by the system and for notifying operators that there’s a recurring fault, or a commonality between breakdowns.

Where home life and home working meet

Her three KPI (Key Performance Indicators) streams require fairly strict time management, given she is also coordinating a family life. She shares a work room at home with her son Christopher, 20, who’s studying veterinary science at university. It looks out on a typical Queensland suburban landscape with beautiful old ‘Queenslander’ timber homes; and her virtual meetings with colleagues are often conducted against the background noise of flocks of cockatoos shrieking around the neighborhood. Claudia’s younger son Quinn’s talents tend more towards the arts, and for his recent, 11th birthday, she crocheted Star Wars characters for the guest goodie bags, channeling the popular Japanese pursuit known as amigurumi — knitting or crocheting small stuffed figures from pop culture. “I’m still an amateur, but the kids loved it,” she says. Although neither of her sons is interested in engineering, she says, “They know I deal with rotating equipment, and that I help people with highly technical issues — they tune me out when I get on the phone.”

The value of remote monitoring and remotely accessed expert assistance was most powerfully brought into focus during COVID-19 lockdowns and now ongoing disruption to onsite operations. But some operators were ahead of the pandemic curve, says Claudia. She gives two regional predictive-maintenance leaders at Chevron — Scott McKay in Australia and Thanasin Prasertsintu in Thailand — as examples of people who identified where they wanted to get to in terms of advanced monitoring and remote operations and started implementing the tools that could take them there.

She says they identified System 1 as a platform that aggregates, visualizes and analyses the data generated by wireless proximity probes, to digitally transform reliability programs through accurate remote decision making.

“It is Chevron’s mission to have the least number of people on site, and more people crunching the numbers,” she says.

The Chevron offshore monitoring experience

At Baker Hughes’ 2021 virtual Annual Meeting, Claudia and Thanasin participated in a panel titled Driving plant wide performance and enhanced outcomes through remote services. Thanasin outlined how in recent years Chevron Thailand has taken vibration data on its offshore rotating equipment in person, with monthly planned maintenance readings sometimes doubled by unplanned maintenance needs. Data collectors would chopper in to gather data and compile it into reports that were sent to Bangkok for engineers to decide whether to continue to run machinery and maintain production; or to halt production in favor of repair or maintenance of critical machinery. Resolutions frequently took days.

Claudia Penarrieta says it is quite common in the energy industry for centralized diagnostics experts not to have immediate access to data that can support their decision making, but that digital remote monitoring can accelerate and significantly improve outcomes.

Chevron Thailand invested in System 1 condition monitoring system, such that engineers in Bangkok get a direct feed of frequency and amplitude from offshore equipment, which is visualized in the software. “We recently received an alert on the platform that the engine was experiencing high vibration,” says Thanasin. “Using System 1 we could determine right away that the vibration was not due to the process chain, but that the vibration was coming from the rotor.” Being able to quickly decide to replace the compressor rotor saved visiting the platform to gather more data, potentially investigating the wrong equipment, and perhaps unnecessarily restarting the compressor. Thanasin estimates that on this occasion alone instant digitally enabled remote analysis saved two days of production. He adds that as part of the project, an initial 100 wireless Bently Nevada proximity probes that transmit data via the Ranger Pro online have also been installed on reciprocating compressors and piping, to help prevent shutdowns or premature failures.

Software champion

Claudia has made it her mission to drive a greater understanding of the applications of System 1, both within Baker Hughes and among the company’s customers. She says its capabilities in remote monitoring of both rotating and stationary equipment is underutilized. “You can monitor anything you want to; you can put alarms on anything you choose; you can make your view screen as versatile as you want, and you can create rules that make your life easier.”

At Chevron, Thanasin Prasertsintu looks forward to tying the data from critical and less critical machinery into the System 1 platform, and, he says, “As early adopters of the wireless technology, we now have the opportunity to leverage this solution across our business unit. We have a chance to learn and apply this to other sites.” He gives credit to his management team, for their leadership and support in the region.

''As early adopters of the wireless technology, we now have the opportunity to leverage this solution across our business unit.''

Thanasin Prasertsintu, Predictive Maintenance Leader at Chevron in Thailand

Says Claudia, “It takes a certain kind of people to have that vision.”

She anticipates that the machine-learning extension to System 1 will take another year or two of testing and development by her far-flung team but looks forward to working with the visionaries at Chevron and in other organizations to bring its promise to fruition.

It was pre-COVID physical globetrotting — travelling to sites and customer facilities — that piqued her passion for amigurumi: “I became tired of watching TV in hotel rooms during my time off each day.” Post-COVID, she’s still hooked on crochet, but remote working has unexpectedly expanded her work horizons, to encompass not only the leadership and sophisticated “help desk” service she provides her colleagues, but to focus on creating technologies that will transform the near future.

Energy Forward Stories

Sign up to stay up to date on the latest innovations and people shaping the future of our industry.