Highlights

Highlights

Benefits

- Reduce coring trips with efficient core barrels

- Eliminate core sample milling and accommodate multiple jams

- Enhance coring efficiency with longer coring assemblies

Applications

- Fractured formations

- Slanted formation faults

- Interbedded shales and expanded clays

Overview

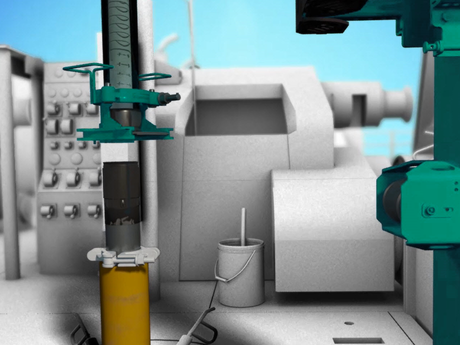

Minimize the costs and delays of core jamming with the JamBuster™ jam mitigation coring system from Baker Hughes. With its telescoping core barrel sleeves, the JamBuster system allows coring to continue after a core jam—letting you avoid the expense of unscheduled trips out of the hole.

Resolve jamming issues in the well

The JamBuster system’s concentric inner core barrel sleeves are incorporated into the Baker Hughes HT series™ heavy-duty core barrels. The sleeves are secured to the non-rotating inner barrel by shear pins, which are set with a shear strength according to the formation’s properties.

If a core becomes jammed in the core barrel, the increased weight-on-bit causes the inner pins to shear and telescope the first inner sleeve and jammed core up into the barrel. Coring continues and begins to fill the second sleeve. A second jam will shear the next set of pins, causing the second sleeve and its jammed core to telescope up the inner barrel.

The coring operation can continue again without interruption. Depending upon the barrel size, the JamBuster system can accommodate three to four successive jams before pulling out of the hole, reducing the number of coring trips required to recover the same amount of core.

Run the JamBuster coring system in your wellbores with new generation core bits to obtain core diameters of between 21/8-in. to 5¼ -in. with various barrel configurations. And to protect your core samples from contamination from drilling fluid filtrates, deploy the JamBuster system with the Baker Hughes CoreGard™ low-invasion coring system and gel coring technology.

With the JamBuster coring system as part of your reservoir analysis toolkit, you’re assured quality core samples acquired at lower cost and risk, maximizing efficiency at the wellsite and reducing nonproductive rig time.

Contact us today to learn more about how the JamBuster jam mitigation coring system can improve your coring efficiency in jamming-prone formations.