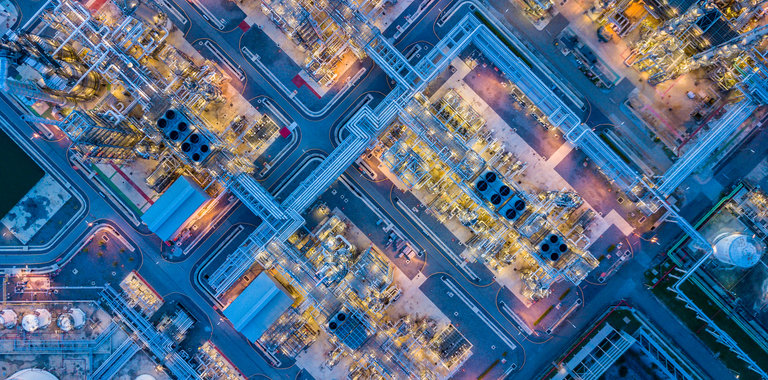

Advancing new energy frontiers with carbon capture technology

We are committed to driving growth in carbon capture technology through a combination of in-house research and development, partnerships, and new ventures.

We have already made a number of investments in carbon capture technologies to advance the decarbonization of energy and industry.

Technologies that meet the needs of your carbon emissions challenges

Different post-combustion technologies offer different benefits and can be applied to capture CO2 emitted by cement factories, gas turbines, waste-to-energy plants, reformers, and steel mills.

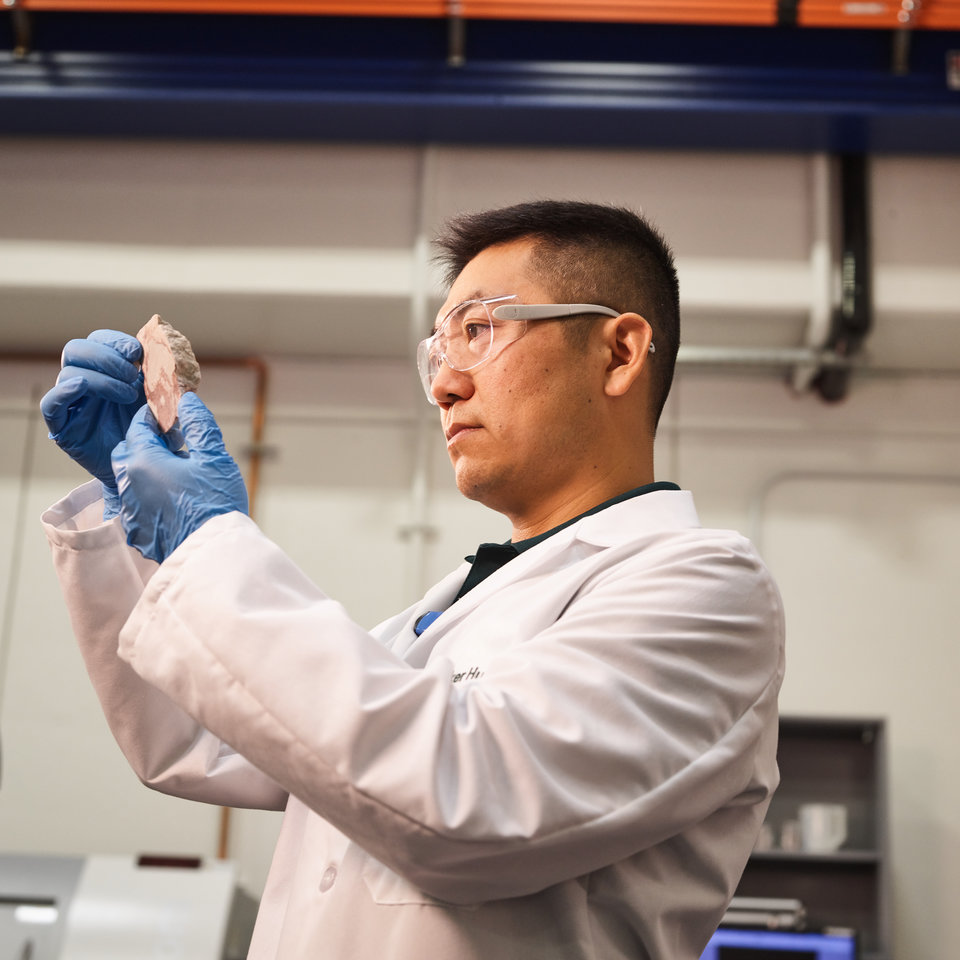

Our subject matter experts are committed to identifying the right solutions based on our customers' specific needs. And we offer a selection of commercially ready solutions, such as our chilled ammonia process (CAP).

Our evolving our carbon capture capabilities

CAP is a post-combustion carbon-capture process that uses a non-proprietary solvent formulation based on readily available ammonia. It has achieved technology readiness level 7 according to the H2020 definition.

-

High CO2 purity and delivery pressure

-

Tolerant to oxygen and flue gas impurities

-

No degradation + no emission of trace contaminants

-

Efficient capture of CO2 (90%)

-

Low-cost, globally available reagent

Our CCC technology uses centrifugal forces to distribute the solvent employed for capturing CO2—enabling more effective solvent distribution that enhances mass transfer.

CCC has achieved technology readiness level 4.

- Lower CAPEX vs. conventional systems

- Easy installation and retrofittable

- Compact and efficient

- Less solvent inventory vs. conventional systems

- Solvent agnostic

MSP is a post-combustion, carbon-capture process that uses a novel solvent formulation based on readily available potassium and ammonia. It has achieved technology readiness level (TRL) 4 and a pilot for demonstrating TRL 6 is under execution.

-

No solvent degradation

-

Reduced generation of by-products

-

Reduced water use

-

Reduced energy consumption

-

Lower emissions to atmosphere

As a leader in CCUS technology and project development, Baker Hughes is uniquely positioned to support our customers' complex project requirements and enable new types of partnerships.

- Flexible, modular solutions from discrete products to a project development partner

- Outcome-based solution models

- Joint industry partnership and consortia

- Pre-FEED/FEED surface facility design

- Project economics and regulatory support

News and resources

While significant progress is being made, the industry needs to see a strong business case for CCUS. In addition to developing policies that promote investment in CCUS, DOE is investigating new ways to extract an economic benefit or additional value from capture CO2.