Wendy Lam’s first studies were in engineering. Now she is a decarbonization thought leader working on strategic partnerships and commercialization for subsea applications at Baker Hughes. Based in Oslo, Wendy is a native of Hong Kong who grew up in Canada. We discuss why diverse thinking is at the core of her successful approach to collaboration.

I have a lead role in our systems and technology team working with customers and industry to identify needs, define our value propositions, and plan commercialization for the latest technology to drive the energy transition towards a secure and sustainable future. That tech is often built on tradition and expertise we have developed over decades and combined with completely new innovation driven by new applications. I work with customers and our product managers every day.

What’s really great about working in subsea and traditional oil & gas is that there is genuine will, leadership, and investment to drive a change. And that is drawing different kinds of customers, talent, partners, and perspectives.

One of the best examples of building on that past expertise is from our carbon capture utilization and storage (CCUS) projects.

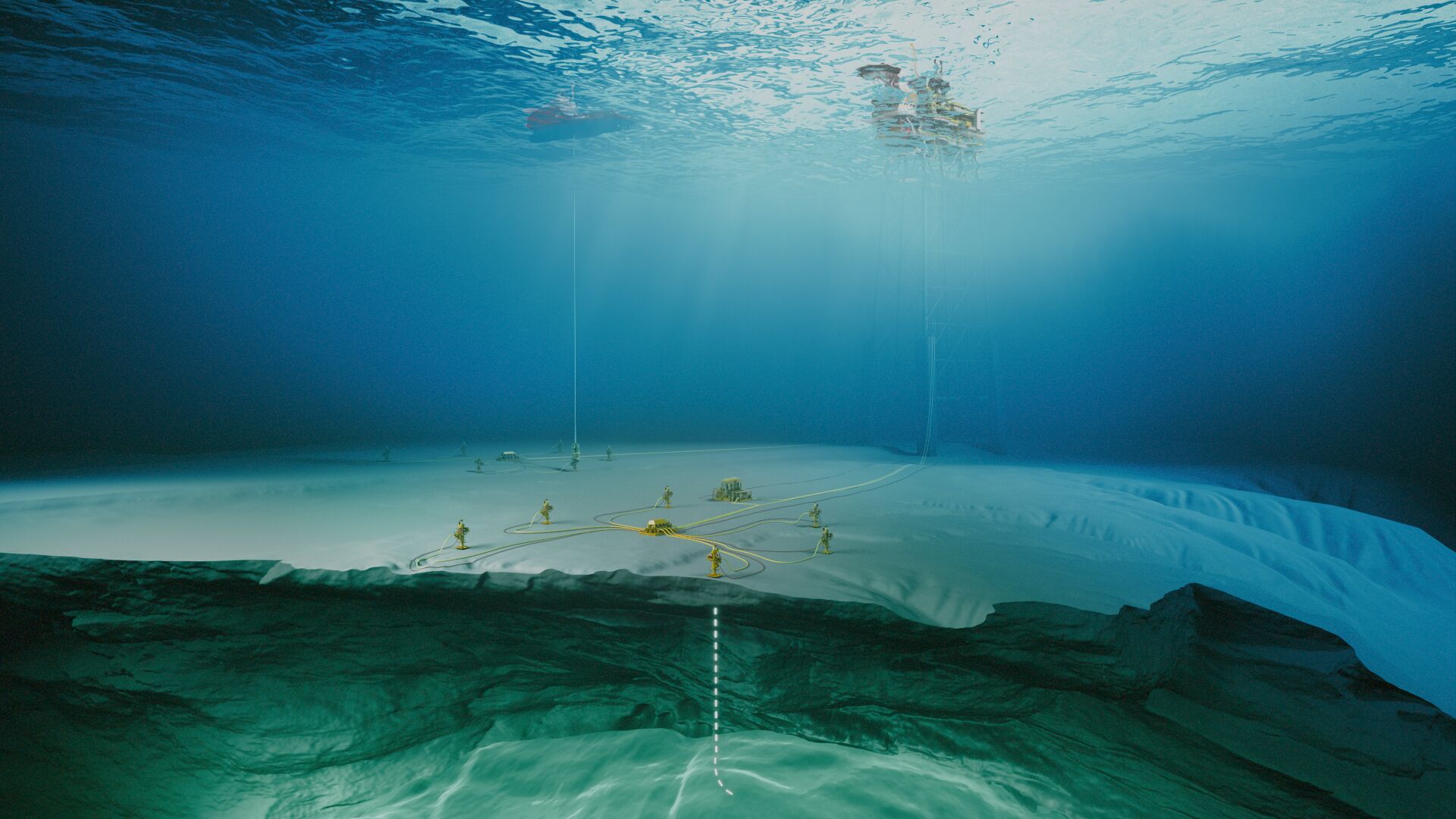

Everybody's talking about reaching net zero. But that's not going to happen unless there's some element of carbon capture and storage, and to do carbon storage at a large scale, you really need to look at some of these offshore subsea reservoirs. And that's exactly the type of project that builds on all the subsea technology experience that we have within Baker Hughes.

CO2 storage on these projects offshore is dependent on traditional subsea systems technology for injection, pressure containment, and operational monitoring in safe, effective ways. There is no other available tech that can do this today. At the same time, we need to apply new thinking and standards to improve CO2 handling, enable longer step-out distances of storage wells from shore and lower costs. Electrification of subsea systems is a critical new technology that can fulfill these needs.

Electrifying the subsea system gets rid of the subsea hydraulic systems, so instead of pumping loads of hydraulic fluid down into the seabed to control the equipment, we’d have a simpler electric line to control it. With this simpler infrastructure, you may even enable removal of platforms and infrastructure offshore in a ‘subsea to beach’ concept. The end solution can be cheaper, cleaner, and safer.

I've never seen as much demand for measuring actual CO2 footprints or emissions as in the last 18 months.

It started with customers asking for specific measurements in the sourcing process. We had to submit our bid responses quantifying carbon footprint of our solutions. And now it’s just part of regular conversations.

We have Technology Advisory Boards with all our key customers where we align our technology strategies and roadmaps. They are asking us, “What are you doing to reduce emissions?” But you can't really talk about that unless you can measure emissions in a good way. So, what we do right now in all our R&D projects is use a lifecycle analysis (LCA) approach to measure the CO2 footprint of our supply chain – manufacturing, processing, and the delivery of the equipment to our customers. It's becoming a core part of all projects.

The LCA approach helps us understand not only our immediate emissions but also our upstream and downstream emissions impacts (Scope 3 – indirect emissions) that affect our customers. Our Scope 3 can impact greatly our customers’ Scope 1 and 2 emissions (from direct operations and electricity usage).

Learn more about Scope 3 (value chain) carbon emissions accountability.

In the past, emissions reporting was largely done because of compliance or because someone needed to submit a report. Although there is more demand today for CO2 footprint measurement and emissions management, it is not being done in a consistent manner. We need to agree within our industry on a broader standard of how we measure CO2 so we can facilitate more collaborative discussions and problem solving.

Another challenge has been getting measurements to a granular enough level that is accessible and useful for people – the engineers, the systems designers, the project leads – to be able to make decisions on projects that actually have some impact on the emissions.

Because of the varying standards and detail of CO2 studies traditionally, there is not a very big library of learning. The good thing is that we are building that right now at Baker Hughes. So, you could say one of the biggest challenges is actually pretty exciting for us because we get to build a whole knowledge base on CO2 lifecycle analysis.

Collaboration is one of these words that's overused. The way I like to think about collaboration in the energy transition is that it becomes a way of thinking that includes thoughts and ideas that may be radically different from before.

In subsea oil and gas, which is where I work, you have people with decades of experience, and who have built very deep expertise. The problem with having deep expertise in any field is that you start to build blinders. There are some things you cannot see.

So, when the industry is calling us to work in a different way, we need to have external connections with people who are not like us to see things a different way. This is where collaboration comes in. And for this to be successful, we need new models of leadership and teamwork.

A couple of other examples: One, we are applying subsea power technology for offshore wind developments where we have a completely different customer and partner base who have different timelines, expectations, and norms. We’ve built a concept that significantly simplifies and lowers cost for offshore wind, despite using ‘expensive oil and gas technology’.

Another, we are working with a Norwegian CCUS partner where we are allowing a diverse set of stakeholders with oil and gas, marine, renewable power generation, and gas transport expertise to openly develop a system solution, early on from the concept-select phase. It is forcing us to rethink how we apply existing standards and operational approaches to enable a cost-effective solution for offshore CO2 transportation and storage in Europe.

Dealing with diverse and conflicting points of view can be challenging – it is easier to work in a group who all think alike. But we cannot afford to do that now. We need to take the efforts to build new links and do some trailblazing into territories not so well-traveled. Learning to be what I call ambidextrous, working with both traditional and new ideas, as we think about the energy transition is going to be really important.

In oil and gas, we don't just get to turn it off one day and go green the next day. The future is not black and white, and you can't have just one or the other. You need to manage what can seem like conflicting ways of dealing with the energy challenge. I think the culture of diversity allows us to think a bit differently around that.

I strongly believe energy transition begins in the cultures of organizations. There's a lot of talk about equality, diversity, and inclusion. It’s not just some fuzzy corporate feel-good stuff. I truly believe it's a competitive advantage. Because if you have that mindset and culture, you can collaborate. This is the mindset for action to get to net-zero and more – it moves us beyond the ‘blah blah blah’.

And it's also an output: If we see a diverse group in a business, to me, that's an output of a culture that is mining for new ideas. At Baker Hughes, this is the way we work every day, and we’re getting better at it.

I know the energy transition makes a lot of people nervous because it's a big change. It’s happening right now and the great thing about Baker Hughes is that we're choosing to lead. And to be a leader in an organization that’s leading the energy transition is super exciting.

The priorities and goals set by our leadership, the investments we’re making, our global infrastructure, and the technical minds we have within the company – we are well-positioned to really have an impact…not only on our industry, but also on our planet. We’re building on what we already know and using that to shape our future.

Energy Forward Stories

Sign up to stay up to date on the latest innovations and people shaping the future of our industry.