Highlights

Benefits

- Eliminates wire connections/port plugs minimizing risk of misfires/NPT common in conventional systems

- Reduces ILT associated with assembling/verifying the system before each deployment between wellhead connections

- Enhances production efficiency – cluster per stage customization, type of charge used, shot-per-foot, phasing designs

- Enhances safety at the wellsite and is compliant with API RP67

- Graphical surface interface is fast and informative - quick pulling speed while perforating clusters and verifying initiation

Features

- Pre-assembled system ready for rapid connection

- Offers a simple, and minimalistic design

- Easier to navigate software

- Fully integrated cartridge design with non-sequential addressability

- Detonator/Igniter detection

- RF safe initiator, compliant with API RP67

- Enhances production efficiency through versatility

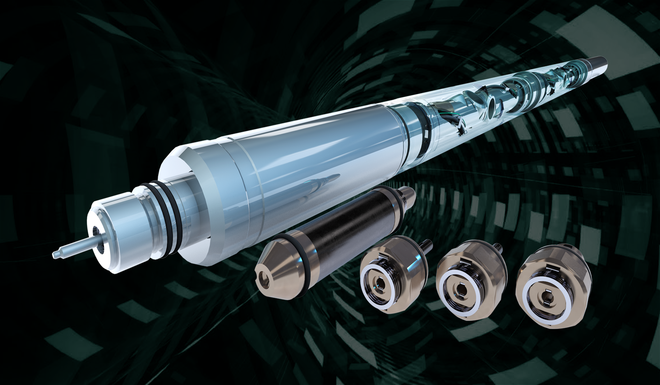

- Modular, plug-and-play gun system

- Reliable performance – top cartridge works as a voltage regulator

- Compatible with industrial standard shaped charges

Applications

- Pump down perforating in conventional and unconventional wells

- Plug-and-perf stage completion

The TrueSelect™ advanced pump down perforating system offers a quicker, smarter, and more versatile plug-and-play gun system for conventional and unconventional wells.

Quicker

The TrueSelect system features a fully disposable, pre-assembled gun ready for rapid connection at the wellsite to substantially reduce operational time. Because this pre-wired system has been quality confirmed –electrical connection in the field, nonproductive time, and misfire risk can all be eliminated. The simplicity of the assembly at the wellsite also helps to avoid some of the common challenges associated with conventional pump-down perforating systems. With this system, you can:

- Simplify workovers and eliminate post-run maintenance through fully disposable components

- Get the assurance of a pre-assembled, single-pressure bulkhead within each tandem sub, minimizing component failures and human errors

- Eliminate electrical connections reducing assembly time between deployments

- Reduce make-up length enabling more clusters in a single run – up to 30 guns

The TrueSelect system is also easier to navigate and incorporates software with a graphical interface that quickly guides the user through system check, addressable switch verification, and on-the-fly initiation of each perforation cluster.

Smarter

The TrueSelect system increases safety, reliability, and efficiency at the wellsite with a fully integrated cartridge design with non-sequential addressability. This means that:

- Address duplication on the rig site requiring delays to reprogram or swap guns is eliminated

- Each cartridge switch has its own unique address to individually identify each gun, igniter, release tool, and firing head

- Each unique address is used to identify the physical position in the gun string, allow shot validation, and provide the ability to skip guns if desired

This smart system also offers detonator detection in each cartridge to safely and instantaneously validate the connection of the detonator or igniter to the switch after the gun/plug is fully assembled. This validation can be checked on surface prior to and during deployment and is performed every time the gun is accessed. Validation can be continuously monitored at any point during the log with no interruption to operations.

Wellsite safety is enhanced through radio frequency (RF) safe compliance with API RP67, and an internal active detonator shunting system guarantees maximum safety during assembly and operation.

More versatile

The TrueSelect system offers one of the most versatile plug-and-play perforating systems on the market. Designed to enhance production efficiency through versatility, the system is highly customizable in terms of the number of clusters per stage, the type of charge used, and the shot-per-foot and phasing designs utilized.

This modular push-and-play gun system features a plug-in switch, and:

- Integrates the switch circuit board with the detonator in one cartridge

- Easily adapts to hardware changes with minimal intervention by the user

- Eliminates gun wiring and the use of wire connectors during assembly and arming

The top cartridge serves as a voltage regulator and functions as a safety switch compliant with API RP67 for enhanced reliability, while a fixed power output remains constant regardless of changes to its input voltage or load conditions. This makes it insensitive to high resistance/long wireline cables for enhanced signal reliability.

Versatility is further enhanced through consistent entry hole sizes in various penetration depths, shot phasing, and densities. Although designed to incorporate Baker Hughes TrueJet™ uniform-hole perforating charges, the system also offers compatibility with any industry standard consistent hole-shaped charges.