Highlights

Highlights

Benefits

- Maximize reliability and availability through customized solutions, optimized activities, and advanced technologies

- Direct access to vast OEM engineering knowledge, to anticipate and solve any support requests

- Take advantage of remote support capabilities without mobilizing personnel to site

Features

- In its 12 years so far, the TTA has conducted 600,000 hours of training in 2,300 sessions with 14,000 attendees

- Wide-ranging capabilities to adapt to any customer requirements, from task-specific experts to multi-skilled personnel

- Advanced technologies and innovative devices to optimize execution and further improve HSE and productivity

Applications

- Midstream and downstream oil and gas

- Planned/unplanned maintenance execution; troubleshooting

- Upgrade, installation, commissioning, start-up

Overview

The Baker Hughes Turbomachinery & Process Solutions (TPS) field service team has over 1,000 personnel across seven regions. Regional teams are fully autonomous to fulfill local customer requests. When additional support is needed for specific expertise or extra capacity during peak demand periods, additional Field Service Engineers can be mobilized from the Field Service Center of Excellence at our headquarters in Florence, Italy.

TPS Field Service Engineers

Our Field Service Engineers (FSEs) provide technical assistance to customers and/or subcontractor site personnel during the execution of field activities. They are responsible for supervising and executing field activities, ensuring that scope of work is performed in line with customer specifications and Baker Hughes standards, quality and HSE requirements. They're accountable for monitoring, recording, and reporting the work progress, and for documenting all non-conformance issues that may arise.

Field personnel skills and training

TPS Field Specialists and Field Supervisors competencies are mapped with a matrix by product and type of activity (eg: service and installation). For each product line, we've defined four seniority levels: FSII, FSIII, FSIV and Master Level. Each technical skill listed in the Competency Matrix is covered by a dedicated training program, and linked to a specific training path.

Technical Training Academy

The mission of our Technical Training Academy(TTA) is to provide TPS Field Specialists and Field Supervisors with the highest quality training on turbomachinery products and services. Our new, enlarged facility occupies approximately 2,200 square meters with nine classrooms/labs, videoconferencing facilities, a virtual reality lab, and a dedicated training workshop.

We've spent over a decade continually investing in and evolving this facility's capabilities:

2008-2009

- First dedicated training building opened

- Technical competency model adopted, and initial training program launched

2010-2012

- Launched the field engineer certification program

- Hands-on facility opened with a $2 million investment

- Heavy-duty gas turbine and centrifugal compressor capabilities

2012-2013

- Commissioning and start-up on real units

- Reciprocating compressor capabilities

2014

- Focus on downstream products, like steam turbines and centrifugal pumps

- Hands-on capabilities

- Enhanced training portfolio

2015

- Heavy-duty gas turbine consolidation, expanding to new different models

- Aeroderivative gas turbines hands-on capabilities

- Pilots for Virtual Reality applied to training

- Multi-skill and cross training program launched

2016

- Virtual Reality from pilot to stable operation in all courses

- Achieved more than 400,000 hours of training

- Created the first full immersive Virtual Reality training scenario

2017-2019

- First Power Transmission training delivered—increasing multi-skill and cross-product capabilities

- Integration of reciprocating compressors, Flow & Process Technologies (valves) and Power Transmission

- Virtual Reality into operation from outage preparation to the in-field execution

- New competency model designed and piloting for Field Service Engineers

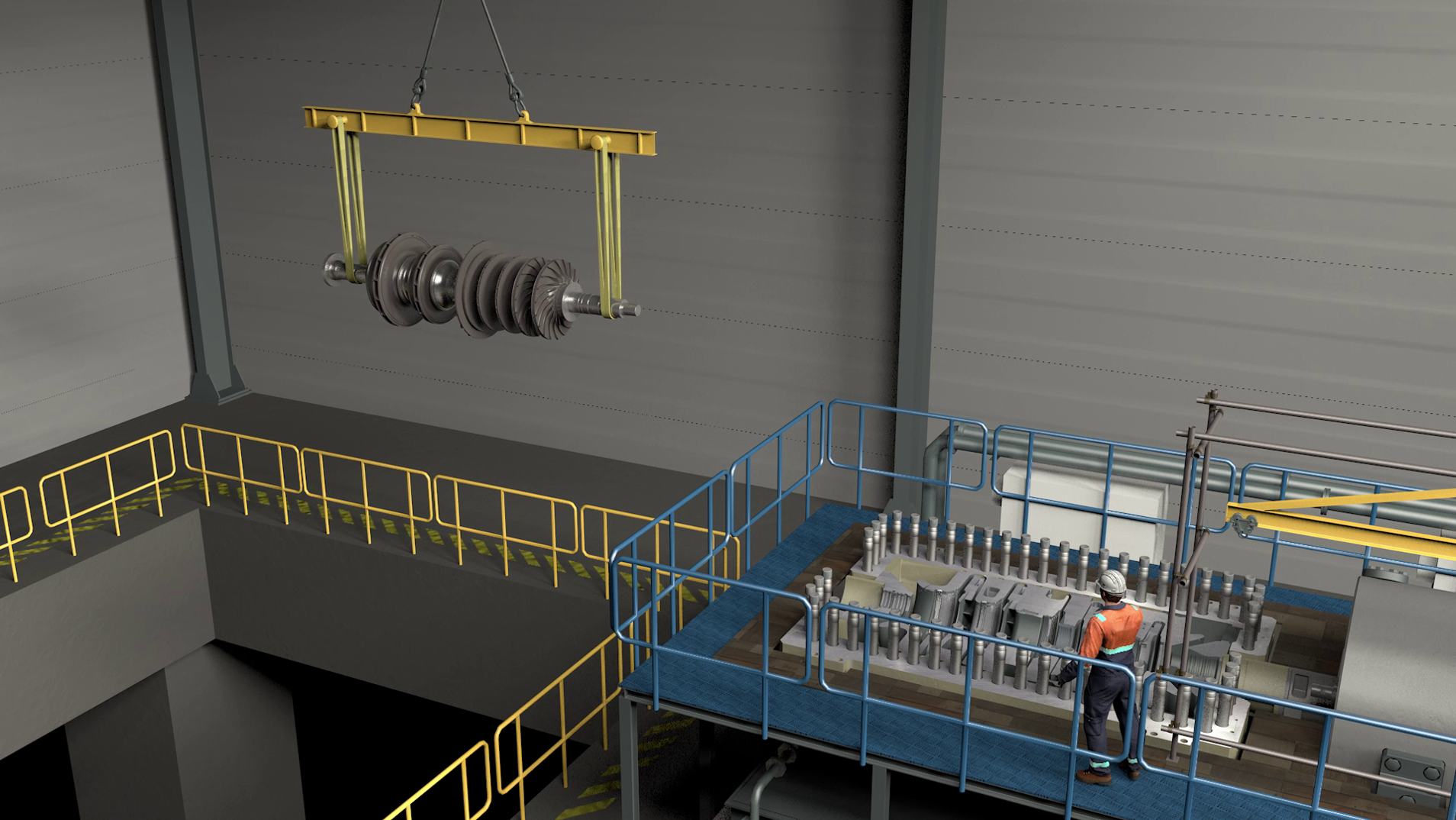

3D digital outage simulation

From laser scanning to outage simulation

We use 3D laser scanners and 3D modeling to build an accurate digital twin of any plant site and equipment in order to plan optimized maintenance activities. The many advantages include:

- Reduced HSE risk (lifting plan, clash and handling analysis)

- Reduced outage duration (lower cost, increased productivity)

- Smart-tools service

- VR technical briefing for workers/operators during outage preparation

- 4D sequence, integrating Gantt schedule