Revolutionizing Industrial CT – With Clarity, Speed, and Confidence

When it comes to inspecting complex and high-value components, industrial computed tomography (CT) is no longer just an option – it’s the gold standard. Whether you're dealing with intricate automotive castings, precision aerospace turbine blades, or cutting-edge 3D-printed parts with hidden internal features, CT delivers the insights you need.

But with increasing demands for speed and precision, traditional CT methods face a challenge: scattered radiation artifacts that compromise image quality and slow down inspection cycles.

That’s where our unique automatic correction technology steps in.

Designed for high-throughput environments, our solution eliminates scatter artifacts at the root – ensuring crystal-clear images, accurate measurements, and reliable results. It empowers manufacturers to meet tight cycle times without sacrificing inspection depth or quality.

Unlock the full potential of CT – with technology that’s as fast as it is precise.

Precision Starts with Clarity – and Clarity Starts with Scatter|correct and Scatter|reduce

In industrial computed tomography (CT), scattered radiation is the invisible disruptor: it creates artifacts, distorts grayscale values, and leads to inaccurate measurements – with potentially serious consequences for quality assurance. That’s exactly where our solutions come in.

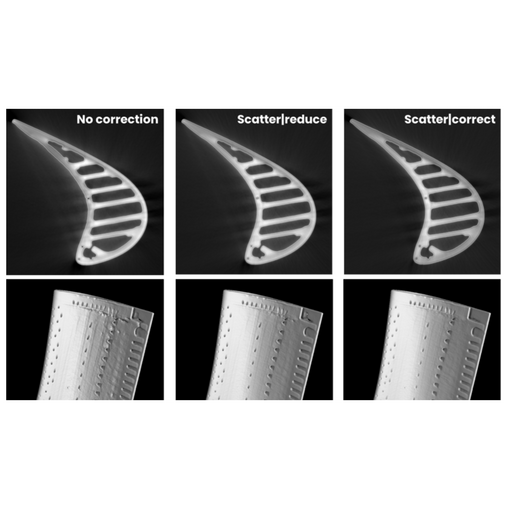

Scatter|correct by Waygate Technologies takes a bold step beyond conventional methods. While other systems merely simulate scatter, our patented technology measures it directly – voxel by voxel, tailored to each individual part. The result? Unprecedented image clarity, even in the most challenging materials.

This innovation combines the precision of traditional 2D fan beam CT with the speed of fully automated cone beam CT – delivering up to 100 times higher productivity. CT becomes not only faster, but also more cost-effective – ready for high-throughput production environments.

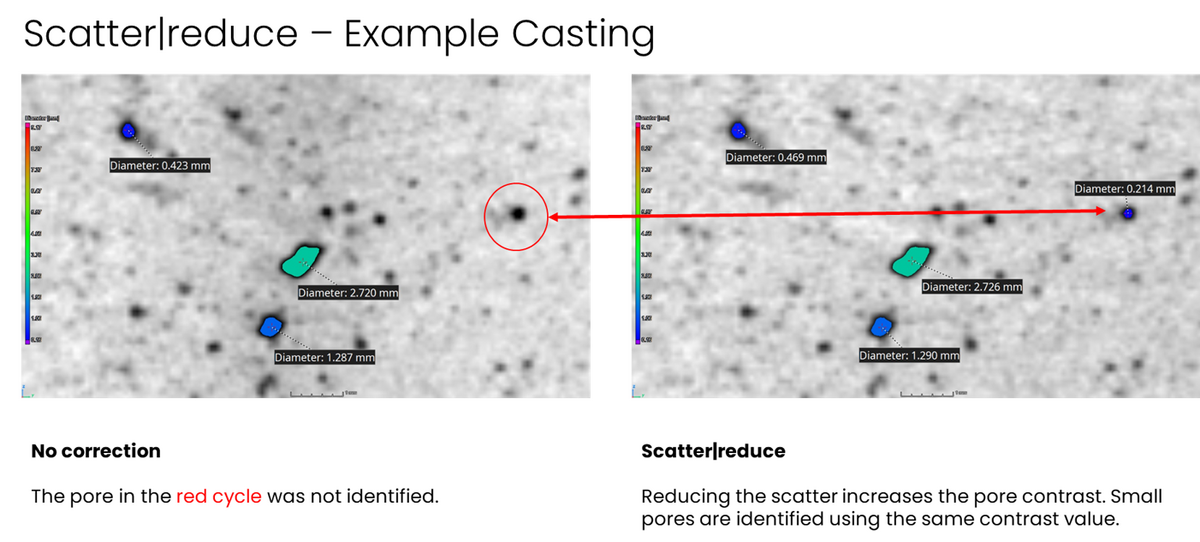

And for those who prefer a software-only approach, Scatter|reduce offers a powerful alternative: it reduces scatter artifacts, enhances surface clarity, and improves measurement accuracy – all without the need for additional hardware.

Scatter|correct and Scatter|reduce – because every detail matters.

Scatter|correct technology is exclusively available as an option for following Waygate Technologies industrial CT scanner:

Scatter|reduce software feature is available for all Nanotom, V|tome|x and Power|scan systems

Scatter|correct starts here

Scattering of X-rays is the main factor for such artifacts in CT. While state of the art scatter reduction simulates scatter based on CAD data or sample’s material properties, Waygate Technologies's proprietary Scatter|correct technology is really measuring the scatter portion of that specific sample in the CT scanner and minimizes it from the CT result for every individual voxel. The new patented method drives inspection throughput and precision of high energy CT applications to scan difficult to penetrate samples with a relatively high atomic number such as metals which are actually performed with highly collimated classical 2D fan beam CT. It allows customers to gain CT quality never before reached with industrial flat panel based cone beam CT. By combining high precision fan beam CT quality with the up to 100 times higher throughput of fully automated cone beam CT, the significantly increased inspection productivity allows CT to migrate from R&D applications to serial inspection on the production floor. The new method is not only substituting slower fan beam minifocus CT in many application cases: in many application cases, 300 kV microCT scans can now be applied for inspection tasks were normally the investment in more expensive 450 kV high energy CT equipment would be required.

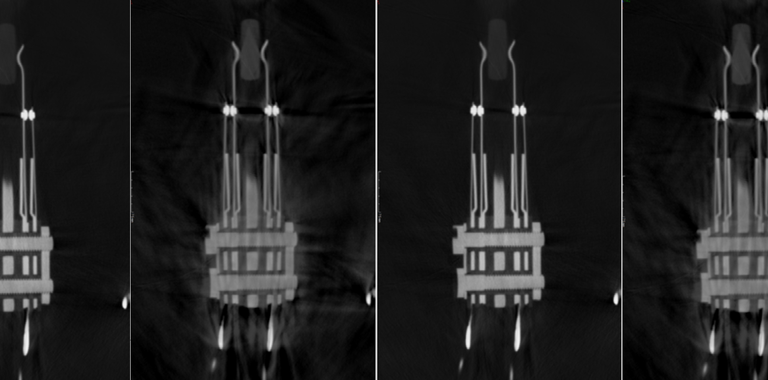

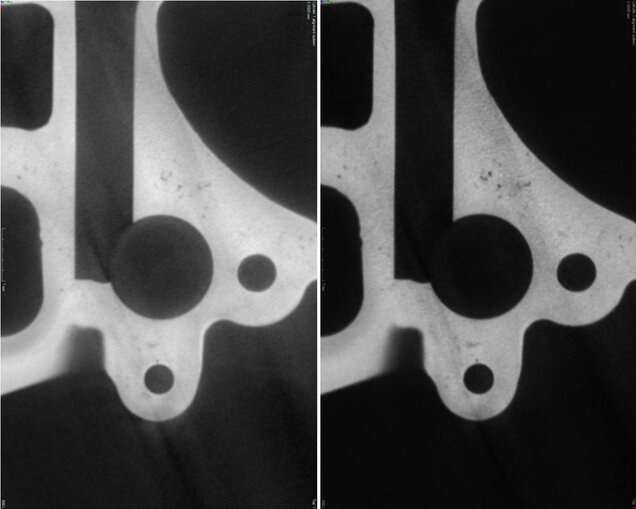

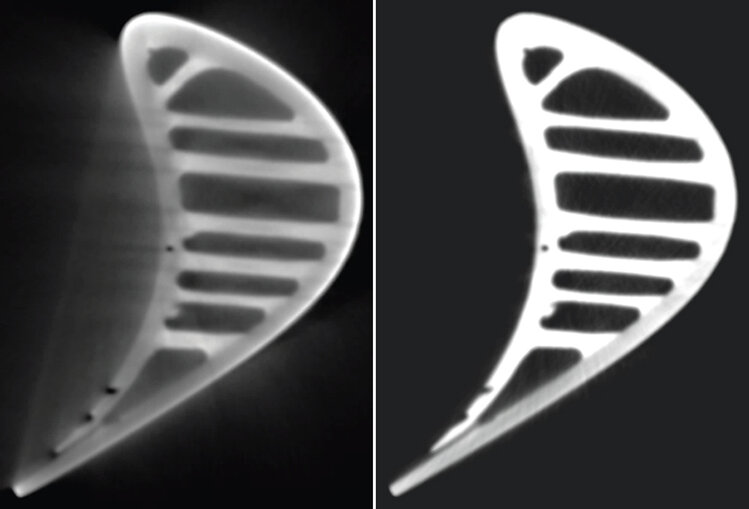

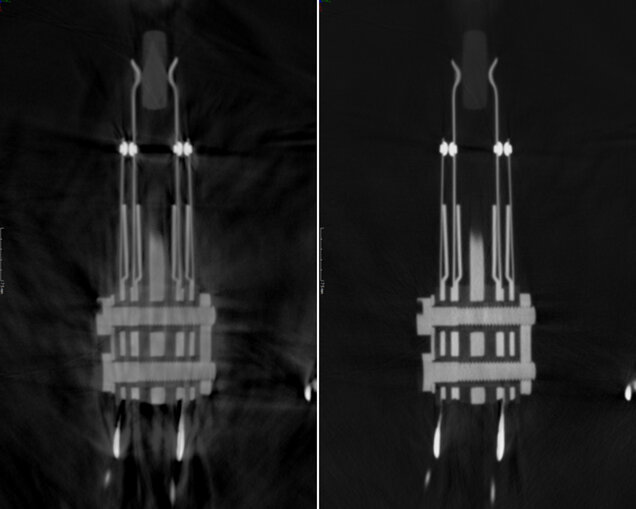

Before and After: Enhanced Image Quality

What Our Customers Are Saying?

Advanced scatter correction

Advanced scatter correction technology also increases measurement precision: 3D metrology with CT always uses automatic surface detection algorithms to determine the surface of the 3D volume to measure. Compared to conventional cone beam CT, the new method allows more material penetration (up to 30%) at the same scan parameters to still determine the exact surface. At same material penetration length, the new scatter correction method allows a more precise surface detection due to less artifacts negatively affecting the metrology results.

Product Highlights

- CT scans can be performed with less energy reducing the need for more expensive higher energy tubes and systems

- Many application cases can be performed with 300 kV microCT scans were others need to invest in more expensive 450 kV high energy CT equipment

- While a typical fan beam CT scan of 1000 slices requires 1 minute per slice = 1000 minutes, a cone beam CT scan requires only 10 minutes

Benefits

- Low artifact high precision performance of fan beam CT combined with up to 100 times faster inspection speed of cone beam CT

- Provides significant quality improvement for high scattering materials like steel and aluminium, and for composites and multi-material samples

- Clearly improved quantitative volume evaluation, e.g. automatic defect recognition (ADR) or precise 3D metrology

- Proprietary patented technology also as an upgrade package for already installed CT systems