Highlights

Benefits

- Modern gas turbine energy source with 44% turbine mechanical efficiency, 56% in electrical power cogeneration

- Higher availability thanks to long maintenance intervals, and modular technology package allowing 24-hour engine swap

- Pressurized LNG compressor startup capability without a helper motor

Features

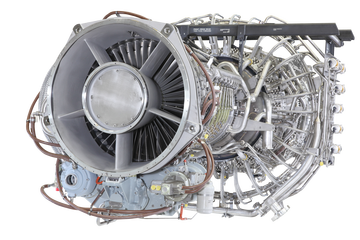

- Powerful and efficient gas turbine engine with high thermal efficiency derived from the GE90-115B — used on Boeing 777s since 2004

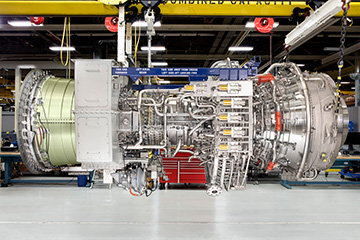

- Compact, modular package for fast installation and lower costs than field-erected units; ideal for stringent space requirements

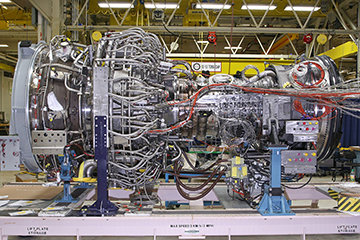

- Designed for easy inspection and condition-based maintenance — delivering high reliability, baseload power output, and maintainability

Applications

- Onshore and offshore LNG projects and gas imports

- LNG export terminals, LNG export facilities, and storage tanks

- Natural gas, natural gas pipelines, renewable energy

- Industrial gas turbine

- Combined cycle power plants

Featured Video

Featured Video

Overview

Overview

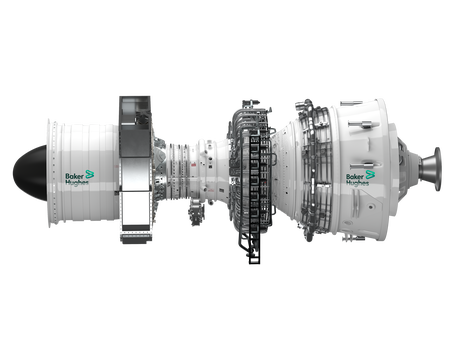

The LM9000 aeroderivative gas turbine has the highest availability, and best-in-class total cost of ownership in its power class. Its DLE technology capability, reduces NOx emissions from exhaust gases while eliminating water use in fossil fuel emissions abatement.

Specification

Mechanical drive

Power (MW/HP)

73.5/98,575

Efficiency (%)

44

NOx emissions (ppm)

15

Exhaust temperature (ºC/ºF)

455/851

Speed (rpm)

3,429

Borescope inspection (hours)

12,000

Hot section inspection (hours)

36,000

Major inspection (hours)

72,000

Package dimensions (m/ft)

13.3x5x18.2/43.6x16.4x59.7 (LxWxH)

At ISO conditions with natural gas fuel, ambient temperature 15ºC, no inlet or exhaust losses, sea level, 60% relative humidity. Package dimensions exclude driven equipment.

Specification

Power generation (50/60 Hz)

Power (MW)

73/97,985

Efficiency (%)

43 to 43.5

NOx emissions (ppm)

15

Exhaust temperature (ºC/ºF)

456/852.8

Speed (rpm)

3,000 to 3,600

Borescope inspection (hours)

12,000

Hot section inspection (hours)

36,000

Major inspection (hours)

72,000

Package dimensions (m/ft)

13.3x5x18.2/43.6x16.4x59.7 (LxWxH)

At ISO conditions with natural gas fuel, ambient temperature 15ºC, no inlet or exhaust losses, sea level, 60% relative humidity. Package dimensions include driven equipment.

Power and speed flexibility

A key design feature is its free power turbine—enabling high-efficiency power and speeds over a wide range of ambient conditions.

Optimized package design

The LM9000 aeroderivative gas turbine‘s modular package design enables shorter manufacturing cycles and faster installation; and its compact footprint helps meet stringent space requirements.

Maintenance and cost advantages

This gas turbine helps reduce CAPEX in the LNG industry because it doesn’t need a helper motor, and the longer maintenance intervals help reduce OPEX.