Highlights

Highlights

Benefits

- Modular designs enable extensive customization to project-specific needs

- Top efficiency over a wide range of operating conditions

Features

- Inlet sections have progressive temperature capabilities up to 565°C (1,050°F) to satisfy any power output requirement

- Turbine exhaust options include a wide range of backpressure and condensing modules with radial or axial configuration

- Low pressure stages can be variable or fixed-speed, and intermediate pressure portion has sub-modules for customization

Applications

- Oil and gas: including urea, ammonia, ethylene, methanol, refinery, syn-fuels, process air, GTL, and LNG/FLNG

- Power generation: including combined cycles, cogeneration, waste-to-energy, and biomass, geothermal, and solar

Overview

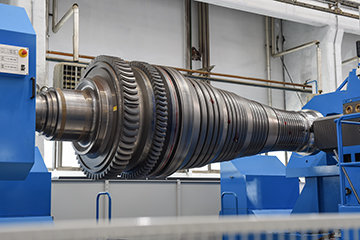

Our reaction steam turbines are based on a modular design to ensure reliability with highest performance. The machines are customized using pre-engineered, field-proven stator and rotor components, optimized and tailored to the thermal cycle requirements to provide higher efficiency over the entire operating range.

As a result, they are an excellent fit in a wide range of oil and gas applications, including urea, ammonia, ethylene, methanol, refinery, syn-fuels, process air, GTL, and LNG/FLNG. They also cover a variety of power generation applications, including combined cycles, cogeneration, waste-to-energy, and biomass, geothermal, and solar.

SC/SAC Series

These single-flow turbines use both impulse and reaction blades for top efficiency over a wide range of operating conditions. Used in condensing configurations, they can have sliding and/or fixed pressure control, up to two controlled or six uncontrolled extractions, axial or radial (up/down) exhaust, and can be base or foundation mounted.

SNC/SANC Series

These turbines have the same features as the SC/SAC series, but are designed for backpressure configurations with dedicated exhaust modules.

A5/A9 Series

These single-casing steam turbines provide the most effective solution for small reheat, very compact design applications. They are configured with a central admission and back-to-back flow path to reduce temperature gradients and minimize thermal stress. Other features include bleeds and an extraction IP section, axial exhaust, sliding and/or fixed pressure control.

SG Series

SG series turbines, in single or double flow configuration, feature a unique design and materials to withstand direct geothermal steam conditions such as saturated or slightly superheated steam, corrosive contaminants, and low pressure. Options include, governing impulse or reaction blades, steam chest partializing system to deal with well depletion, inlet pipe mounted trip and control valves, and axial or radial (up/down/lateral) exhaust.

SDF Series

SDF double flow turbines have impulse and reaction blades designed to accommodate low pressure steam. They can be used like the low pressure body of a two casing turbine, or like a stand-alone turbine for low pressure steam conditions. Used in condensing configuration, they have sliding and/or fixed pressure control, and radial (up/down) exhaust and are typically used as a revamp option.