What is the pulse-echo method in ultrasonic testing of materials?

In this article:

- Pulse-Echo Ultrasonic Testing Is a Foundational NDT Technique: This method uses a single transducer to emit and receive high-frequency sound waves, detecting internal flaws by analyzing reflected echoes from material boundaries or defects.

- Ideal for Thickness Measurement and Flaw Detection: Pulse-echo is widely used to measure wall thickness, detect corrosion, and locate cracks or inclusions in metals, composites, and other solid materials.

- Time-of-Flight and Amplitude Indicate Defect Characteristics: The time delay and strength of the returning echo help determine the location, size, and type of internal discontinuities.

- Portable and Cost-Effective for Field Inspections: Pulse-echo systems are compact, easy to use, and suitable for on-site inspections in industries like oil & gas, aerospace, and manufacturing.

- Waygate Technologies Offers Advanced Pulse-Echo Solutions: With instruments like the Krautkrämer USM series, Waygate delivers high-resolution, reliable ultrasonic testing tools for both routine and critical inspections.

What is the pulse-echo method in ultrasonic testing of materials?

How the Pulse-Echo Method Works

In ultrasonic testing , the pulse-echo method is one of the most commonly used techniques for checking the internal condition of a material. It allows defects, changes in thickness, and other irregularities to be detected without damaging the part being tested. Short sound pulses are sent into the material, and the reflected echoes are received and evaluated.

The pulse-echo method works reliably and efficiently — but only when all system components function together as intended. Whether it's a simple handheld device or a fully automated setup, the basic principle stays the same: sending in a sound pulse and measuring what comes back.

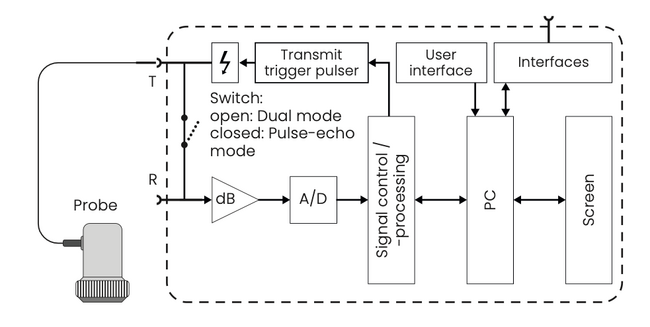

The purpose of ultrasonic equipment used in the pulse-echo technique is to make the difference between “sound Input” and “sound output” technically measurable i.e. so that it can be evaluated. Be it a simple battery-operated Instrument or a test Installation with automatic evaluation and control the same components are always used:

Key Components of a Pulse-Echo Ultrasonic System

1.Controlling unit

This unit determines the sequence of the testing cycle i.e. when to transmit and when to receive and evaluate.

2.Pulse generator

Generates the pulse which in- duces the probe to oscillate mechanically.

3.Probes

The probe transforms the electrical pulses into mechanical oscillations (ultrasound) and vice versa, converts sound oscillations into electrical ones. The transmitter and receiver probes can be identical (single-probe operation) or separate (TR-operation or dual mode, and tandem-operation).

4.Amplifier

The amplifier amplifies and filters the signal received and trans- formed by the probe. The gain can be either linear or logarithmic.

5.A/D converter

The analogue/digital converter digitises the analogue signals for further data processing.

6.Evaluation

Sometimes it has already been done by the gain characteristic. Normally the signals are classified into signals which are either lower or higher than a threshold level. The component which does this is known as the monitor gate.

7.Output

Here the converted and evaluated received signal can be processed further in accordance with a pre- selected program and can be either printed, displayed or stored.

Fig. 5: Block diagram: digital flaw detector

Signal Processing and Display

Fig. 5 shows the structure of an ultrasonic device that converts, amplifies and digitises the incoming signals and outputs them on a screen. In automatic systems, the screen is usually replaced by a suitable output unit. One or more monitor gates control specific time or distance ranges for automatic evaluation.

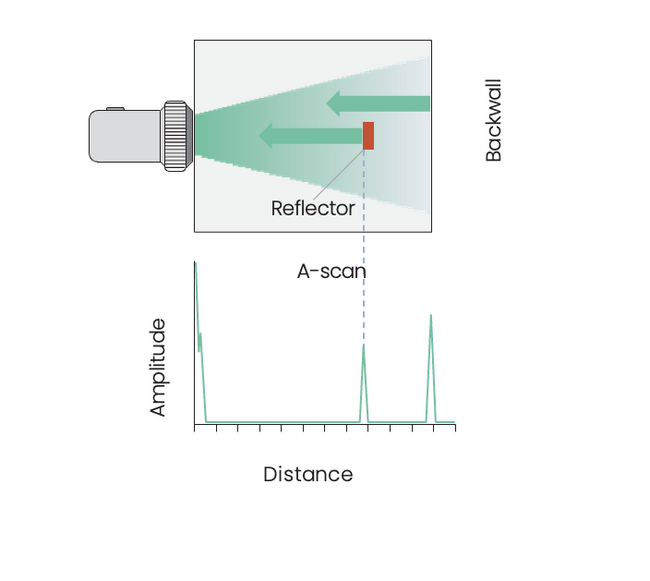

In devices for manual testing, the signal amplitude is displayed on a screen over the transit time (distance): the A-scan (fig. 6).

Fig. 6: Pulse-echo Method with A-scan

Testing Accuracy and Synchronization

When testing it is very important to observe the relationship between the pulse repetition frequency and test cycles (movement of the probe and/or test specimen etc.) If this temporal relationship is not observed, this can lead to considerable errors in the test results, even though all system components function perfectly and the results are reproducible (overlooking of reflectors in the material or multiple counting of reflectors).

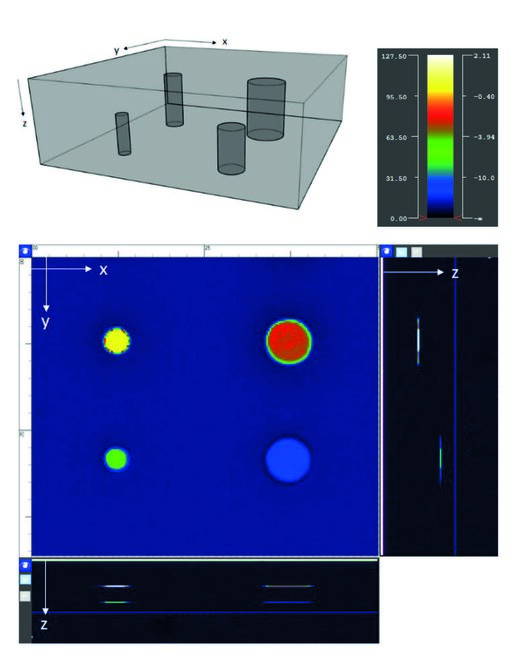

Documenting and Visualizing Test Results

The documentation of the test results is as varied as there are different test problems. If the location of reflectors is displayed on the screen in a two-dimensional top view, a C-scan is obtained.

The B-scan is the view of the ‘transparent’ work- piece from both sides. Echo amplitudes or reflector depths are displayed in colour-coded form with the corresponding colour palette.

These images are widely used as information carriers for inspection findings (fig. 7), especially as inspection results for automated applications.

Conclusion

The pulse-echo method remains one of the most versatile and widely used techniques in ultrasonic testing. Its ability to detect internal flaws, measure thickness, and evaluate material integrity — all without causing damage — makes it an essential tool across many industries.

Whether in manual testing with A-scans or automated inspections with C- and B-scans, the method offers high reliability and adaptability. As ultrasonic equipment continues to evolve, so too does the potential of the pulse-echo technique to deliver fast, accurate, and reproducible results in even the most demanding testing environments.

Information on signal generation and signal evaluation when testing ultrasonically is given in:

- H. Wüstenberg, E. Mundry: Consid- eration of the ultrasonic testing method as an information trans- fer system. Br. J. Non-Destr, Test- ing 15 (1973) no 3, 36—42

- U. Schlengermann: Die automa- tische Ultraschallprüfung mit der Impuls-Echo-Methode alsInformationssystem — Daten- gewinnung, Datenauswertung, Zuverlässigkeit (The automatic ultrasonic test using the pulse- echo-method as an information system—obtaining data, data evaluation andreliability.), Mate- rialprüfung 16 (1974) no 10, 326