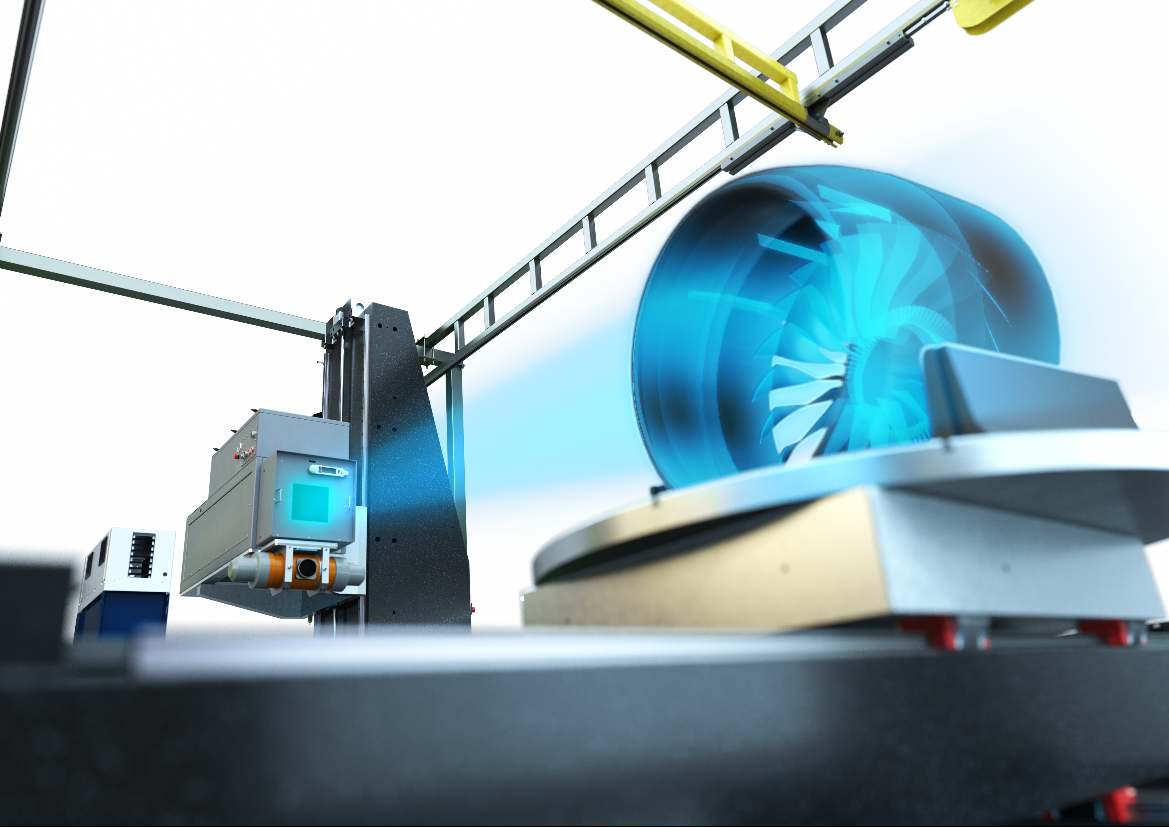

Scan large, complex parts with ease: 9 MeV High Energy CT Scanner

The combination of penetration power and Waygate Technologies' advanced CT features such as Scatter|reduce software make this CT system predestined to scan extremely large, heavy and high absorbing complex parts and assemblies with unmatched speed, precision, and ease of use — enabling faster, more precise inspections than ever before.

High Energy CT Inspection starts here

As global technological demands require increased productivity while tightening regulations require ultimate precision to ensure the highest levels of quality and safety, your inspection technologies need to work harder than ever to keep up.

As the leader in CT technology, Waygate Technologies' inspection systems and services meet those challenges with relentless innovation. The very first of its kind, our 9 MeV linear acceleration CT scanner (LINAC) called Phoenix Power|scan HE leverages cutting-edge software advancements like Scatter|reduce software to scan large, complex parts and assemblies with unmatched speed, precision, and ease of use - enabling faster, more precise inspections than ever before.

Now you can get on-demand access to this powerful CT technology and expertise, without having to maintain any inspection equipment. Our experts are poised and ready to help you take an in-depth look into the internal features you could never see before, so you can understand how to better protect them from failure.

Bring new possibilities to your manufacturing process when you experience the expert-backed inspection system on your own production floor.

When it comes to fast and powerful, but precise and reliable high-quality CT with maximum flexibility, Power|scan HE is the ultimate solution.

Click here to get in touch with a specialist and learn more about purchasing our High Energy CT equipment or utilizing our rental program.

Product Highlights

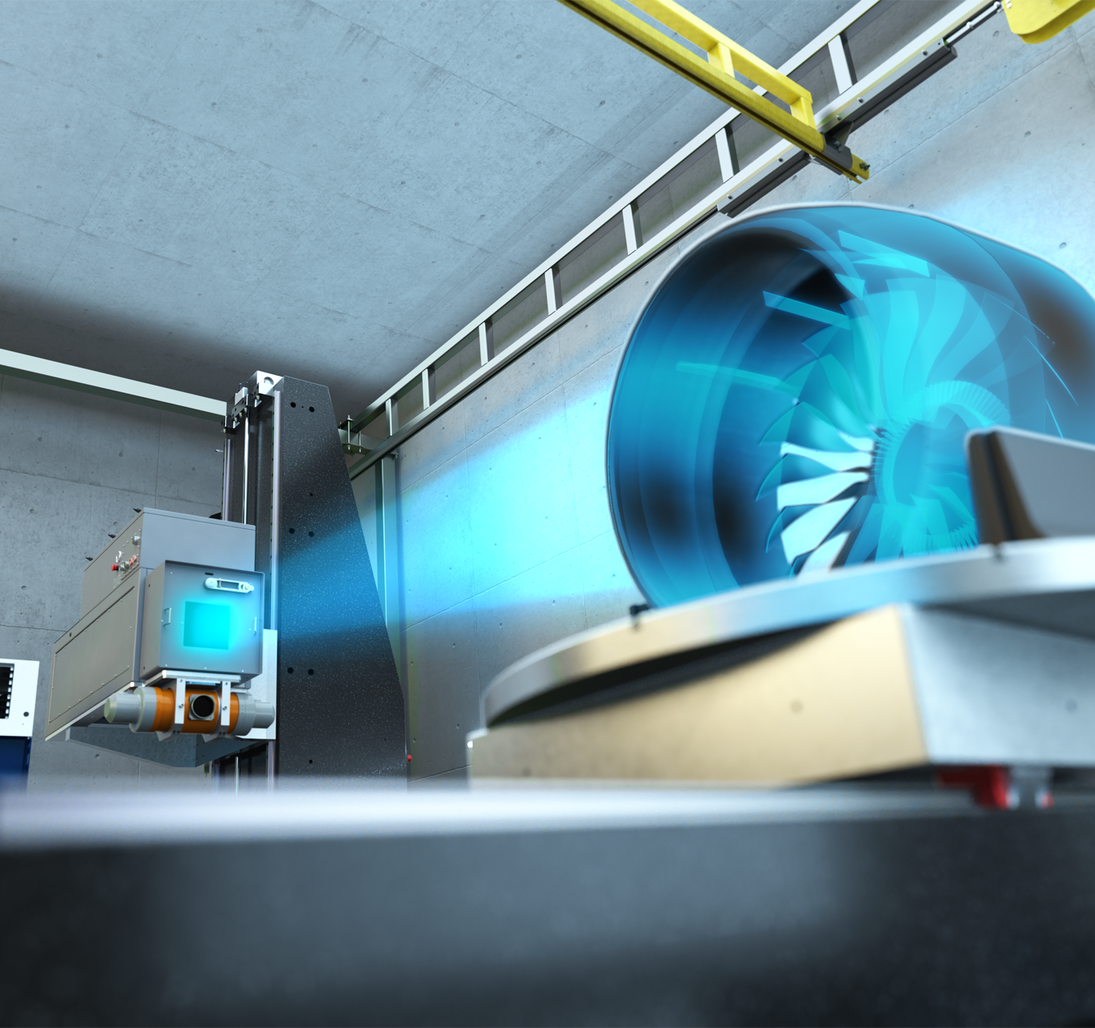

9 MeV LINAC source, 20 times more powerful than the optional 450 kV minifocus X-ray tube

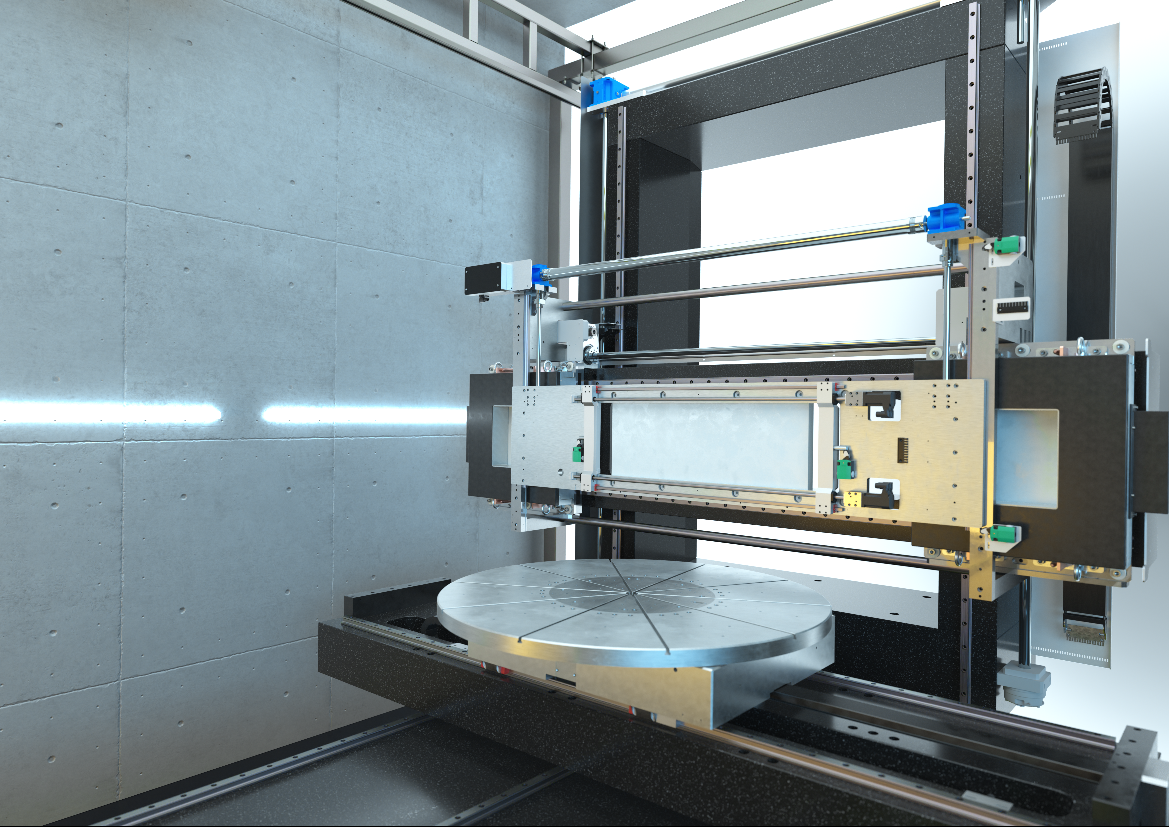

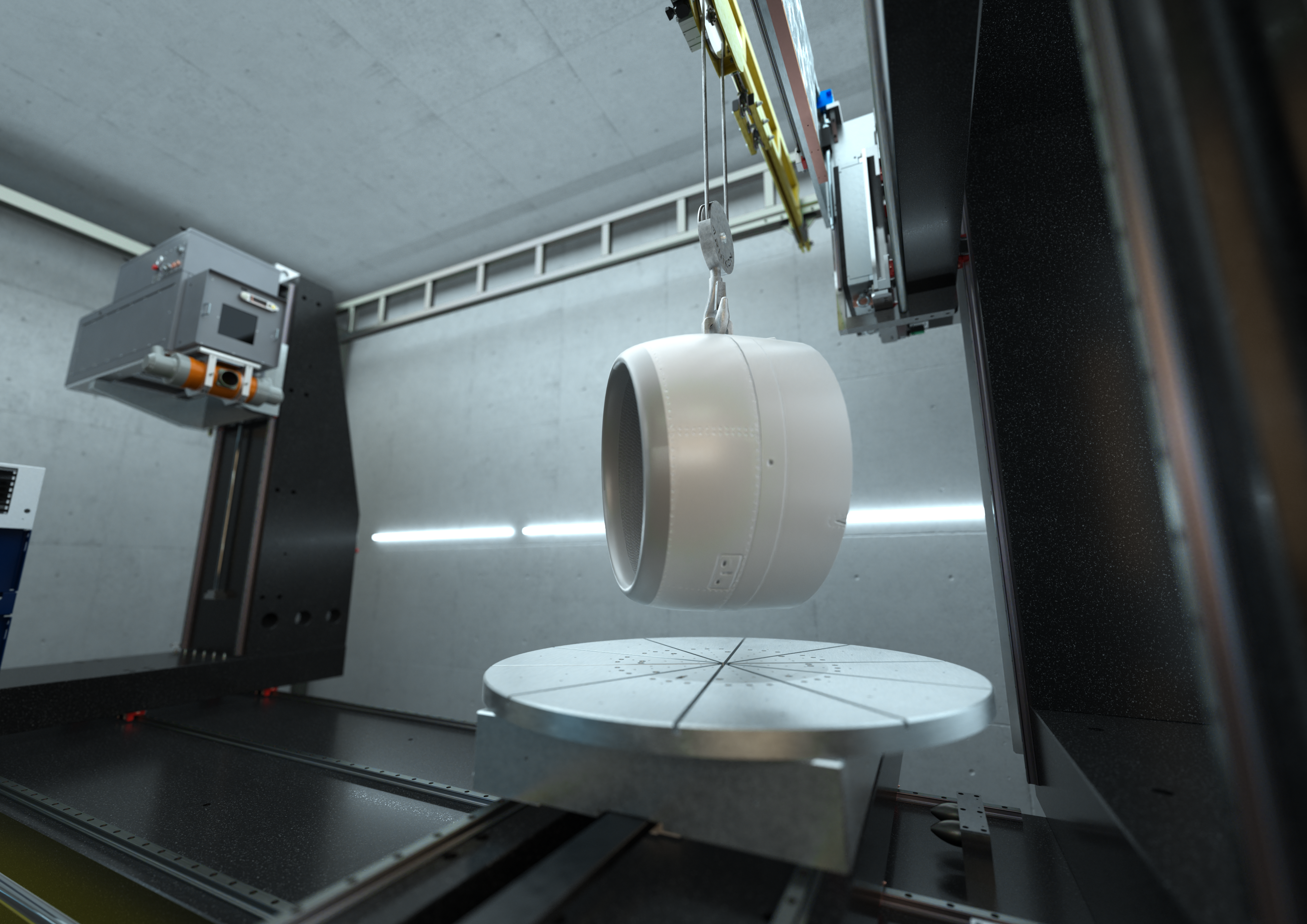

Part weight up to 1000 kg and part size up to 1920 mm in diameter x 2000 mm tall

Flat panel detector with up to 4x detector shift, combined with advanced scatter correction technology ensure high through put

Flexibility to add additional features such as metrology

This system is capable of analyzing these types of components with significant scan time reduction at highest image quality

Benefits

Our system delivers imaging results up to 66% faster, so you can make smarter decisions, maximize profitability, and reduce production time

It takes advantage of flat panel speed and combines it with scatter reducing technologies to create premium image quality at production speeds

Reduce risk and improve confidence with full penetration for crisp image quality

- Scan large castings, additive parts and composites with complex internal structures

The system’s larger manipulator allows for objects of nearly 2 meters in diameter and height to be scanned with both 450 kV and 9 MeV. This enables optimized scan resolution throughout both thick and thin sections of large complex components

What Our Customers Are Saying

Product Specifications

Detail

Data

Primary X-ray source

9 MeV Linear accelerator

Optional additional X-ray source for higher resolution

450 kV / 1500 W Minifocus

Max. CT scanning volume (Ø x height) *

1920 mm Ø x 2000 mm

Max. sample weight *

1000 kg

Min. focal spot (F) / Max. detail detectability (D)

F <1.5mm @ 20 Gy/min/m, optional 1 mm @ 1500 W with Minifocus tube

Geometric magnification

4.5x

Granite based Manipulation

11 axes

Focus detector distance (FDD)

1500 – 5000 mm

Cabinet dimensions (W x H x D) in mm)

Manipulator 8000 x 4300 x 3800 mm (without bunker, console & switch cabinet)

Flat panel detector shift

4x

Weight approx. without / with cabinet *

~48 t / bunker required

Our unique Scatter|reduce software delivers premium imaging results up to 66% faster and with unmatched artifact free quality.

Ideal for high-density industrial CT, the system’s 20x more powerful penetration energy can scan high absorbing metal alloys used for additive components and structure castings.

Scan large, complex assemblies and components that weigh up to 1000 kg, for applications in electric motors, aviation composites, metal space parts, and more. An integrated crane makes loading and unloading parts simple.

At our global Customer Solutions Centers (CSC), we provide you on-demand use of our proven, state-of-the-art, non-destructive X-ray 2D and 3D Computed Tomography (CT) scanning X-ray inspection technologies services and access to our staff on experienced experts. The Phoenix|Power|scan HE system is available for inspection services at Waygate Technologies´ Customer Solutions Center in Cincinnati (USA).