How to describe image quality in CT images?

In this article:

- Detail Detection Sensitivity (DDS) as a Key Metric: CT image quality in non-destructive testing (NDT) is often quantified by the smallest hole diameter that can be visually detected, known as DDS, typically assessed using a Disk Image Quality Indicator (IQI).

- Advanced Metrics for Deeper Insight: Beyond visual inspection, image quality can be described using Modulation Transfer Function (MTF), Contrast Discrimination Function (CDF), and Contrast Detail Diagram (CDD), as defined by ASTM E1695 and E1441 standards.

- Quantifying Image Resolution and Contrast: The intersection of MTF and CDD curves provides a numerical limit for DDS, offering a more objective and reproducible measure of CT system performance.

- Limitations of Standardized Metrics: While DDS and related functions offer valuable benchmarks, they may not fully account for application-specific artifacts, material inconsistencies, or complex geometries in real-world inspections.

- Visual and Analytical Evaluation Combined: The article emphasizes the importance of combining visual assessments with standardized analytical tools to ensure comprehensive evaluation of CT image quality in industrial applications.

Understanding Image Quality in CT for NDT

A common method of describing image quality in Non-Destructive Testing (NDT) is the diameter of the smallest hole that can be visually detected. This corresponds to the fact that most defects in classical NDT are a kind of empty holes such as porosities or cracks.

The diameter of the smallest visually detectable hole is the Detail Detection Sensitivity (DDS), which can be determined directly by examining a CT slice of a Disk Image Quality Indicator (IQI).

Indirectly, but more profoundly the image quality can be described by Modulation Transfer Function (MTF), Contrast Discrimination Function (CDF) and Contrast Detail Diagram (CDD) according to ASTM E1695 and E1441. The crossing point of MTF and CDD yields the numerical limit for DDS.

Both methods provide a DDS value for the IQI and therefore do not take into account application specific CT artifacts, material inhomogeneities, etc.

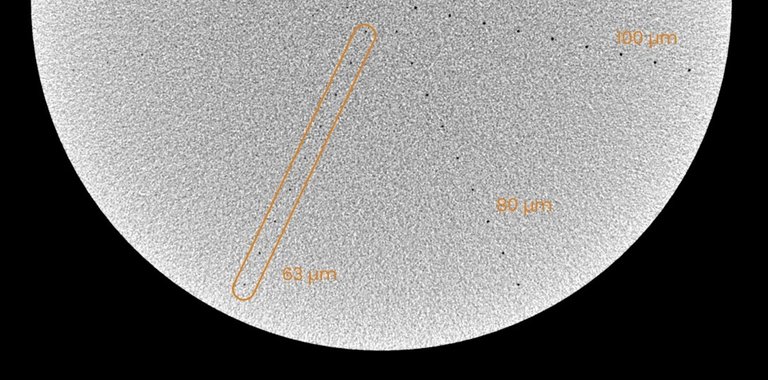

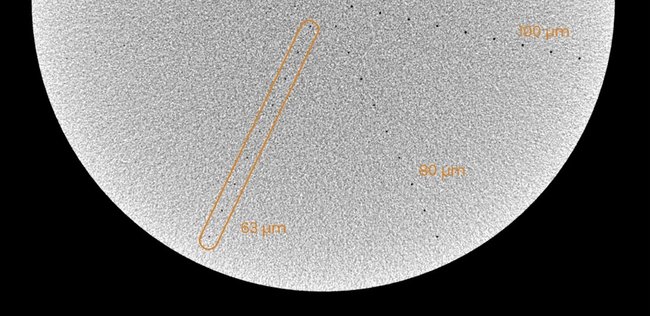

(slice image by courtesy of Dr Uwe Ewert)

Detail Detection Sensitivity - DDS

This is a section of a CT slice of a disk IQI. The disk IQI has rows of holes arranged in a star shape, each with 9 holes of different diameters. The smallest diameter of the holes for which all 9 holes are visible, is 63 µm. The the Detail Detection Sensitivity is therefore 63 µm.