Computed Radiography or Direct Radiography?

In this article:

- CR and DR Differ in Image Acquisition and Workflow: Computed Radiography (CR) uses a two-step process with phosphor imaging plates, while Direct Radiography (DR) delivers near-instant digital images via flat panel detectors—ideal for high-speed, automated environments.

- DR Offers Higher Image Quality but Less Flexibility: DR systems provide superior image resolution and faster processing but are less suitable for field use due to their size, fragility, and higher cost compared to CR systems.

- CR Is More Portable and Cost-Effective: CR plates are lightweight, reusable, and significantly cheaper (approx. €750 vs. €150,000 for DR panels), making them ideal for field inspections and environments with limited access.

- Investment and ROI Should Guide Technology Choice: While DR offers productivity advantages, its high capital cost requires careful ROI analysis. CR remains a practical choice for many applications due to its lower upfront investment.

- Standardization and Industry Adoption Vary: CR is supported by established industrial standards, whereas DR lacks widespread standardization, which can limit its adoption despite its technical advantages.

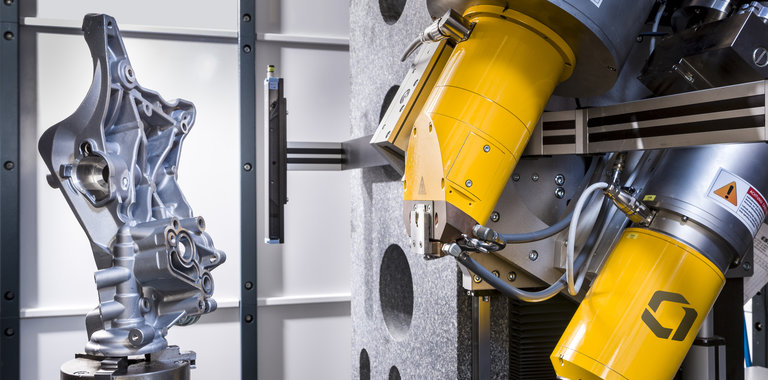

With storage phosphor based imaging plates for computed radiography, the conversion of radiation into an image is a two-step process. The DR-technique, however, immediately (instantly during exposure or within seconds following exposure) produces an image on the screen of the workstation (see figure 18-16). That makes DR extremely useful in automated, robotic, production processes.

Although DR, with the correct exposure parameters, offers a higher relative image quality than CR, flat panel detectors are less suitable for field use and for applications with difficult access requirements due to their physical size (thickness) and inflexibility/rigidness.

Moreover flat panel detectors require a considerable higher capital investment compared to the CR-method. Although the electronics needed for both methods, e.g. workstation, cost approximately the same, a flat panel detector however (~ 150,000 €) is roughly a 200 times more expensive than a phosphor plate (~ 750 €). Hence selection of a DR-solution requires careful considerations with regard to return of investment. (pay back period).

Another aspect which influences the selection between CR or DR is the availability (or lack) of industrial standards. Standards exist for CR, for DR they do not yet exist which hampers wider use of the strong potentials of the DR-method. Initiatives are deployed (2006) to work

on compilation of such standards for DR.

In summary: Numerous aspects with a great diversity such as: image quality, process speed, productivity, portability, robustness/fragility, (in)flexibility of plate or panel, available field space, logistics, environmental issues, capital investment, human investment, (non)existence of industrial standards etc. play a role in the ultimate choice between conventional film or CR or DR including type of DR plate (size and number of pixels) to be used.