High-Resolution Computed Tomography (CT)

In this article:

- Computed Tomography (CT) Enables High-Resolution 3D Imaging: CT uses X-ray or gamma-ray beams and advanced computing to generate detailed cross-sectional and 3D images of internal structures, ideal for non-destructive testing (NDT).

- Objects Are Rotated and Scanned Section by Section: The object is rotated continuously or stepwise while a narrow radiation beam scans it, and a flat panel detector captures absorption data across each sectional plane.

- CT Detects Extremely Small Defects with High Accuracy: Modern CT systems can visualize density variations as small as 0.02% and detect flaws as small as 25 microns, making them suitable for inspecting complex components like austenitic welds.

- 3D-CT Requires Significant Computing Power: High-resolution 3D reconstructions demand large data storage and processing capabilities, with image reconstruction times ranging from 2 to 60 minutes depending on resolution.

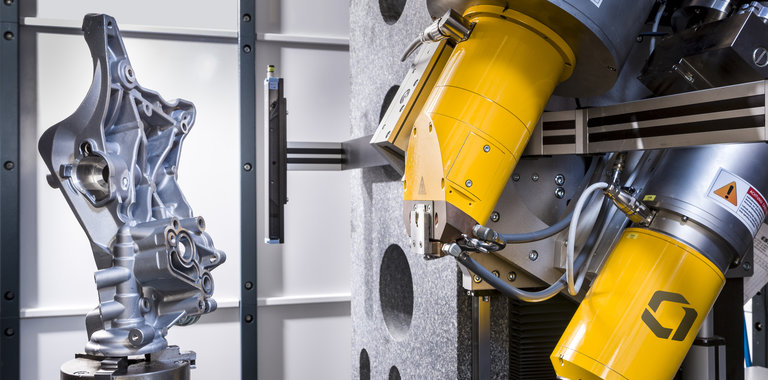

- Widely Used in Industrial and Medical Applications: Originally developed for medical diagnostics, CT is now essential in industries like aerospace, electronics, and additive manufacturing for quality control and defect analysis.

For medical diagnostic purposes, techniques have been developed to obtain a radiographic image with a resolution of approx. 0.5 mm. Powerful computers are used to transform all absorption variations that occur when irradiating with a moving source, into a comprehensive image. The technique is now also used in industry, e.g. for checking miniature electronic circuits as built into mobile telephones. Systems with a resolution of only a few micrometers have already been successfully applied.

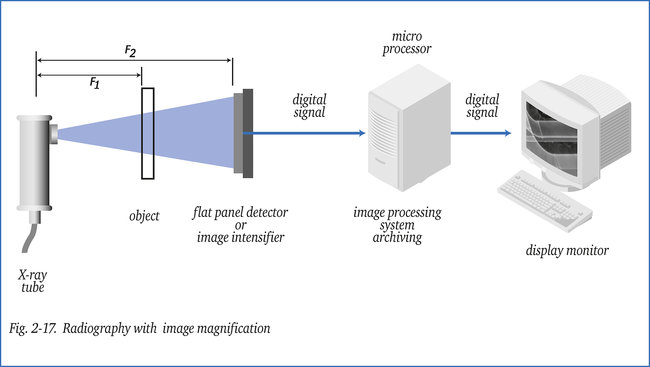

In the arrangement shown in figure 2-17, now the object to be checked rotates (continuously or stepwise by a robot) to obtain a CT-image. The object is scanned section by section with a very narrow beam of radiation (X- or gamma-ray). The receiver in this case is a flat panel detector.

Each individual detector element measures, during a short exposure period, the total absorption across a certain sectional plane of the object. A large amount of data has to be stored and processed, in particular when an image of high resolution is required. A three-dimensional representation (3D-CT) of the radiographic image requires vast computing capacity.

In CT, absorption values are determined with a very high degree of accuracy, which means that the contrast of an image can be varied over a extraordinary wide range. Absorption/density variations of 0.02 % can be displayed in a range of density 6 and over. This offers great possibilities for image processing.

With present day computers, depending on resolution required, the reconstruction-time of a 3D-image runs from 2 to 60 minutes. Increasingly, 3D-CT is used on high-quality castings, even with the extra facility of automatic object and defect identification. The subject of CT

is more elaborately described in the booklets (German) “Die Röntgenprüfung” and (English) “The X-ray Inspection”.

To analyse defects, 3D-CT systems exist which are able to accurately size random oriented cracks or other (planar) defects with a width of only > 25 micron. Such a system can be used to evaluate (flaws detected with other methods) in for example austenitic welds

(e.g. nuclear components) a task almost impossible to perform with ultrasonics.