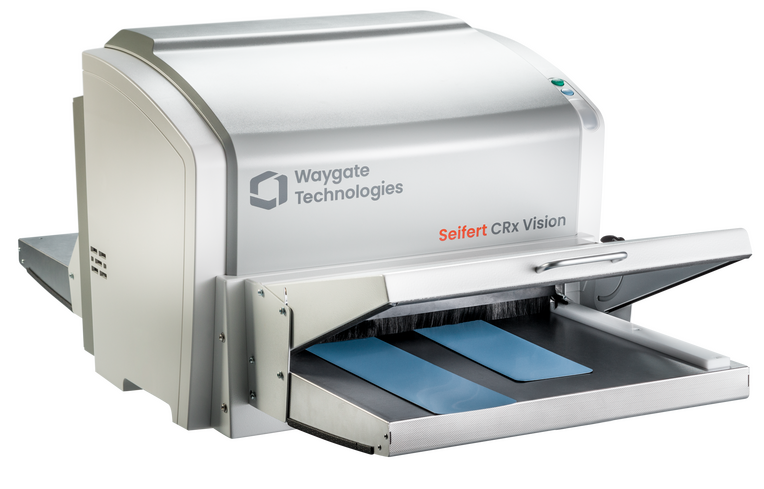

CRxVision

Versatile Computed Radiography (CR) tabletop Scanner

CRxVision is a high-resolution weld inspection and all-purpose computed radiography scanner from Waygate Technologies.

Offering a resolution between 70 and 35 micron, the scanner is developed to cover the stringent ISO 17636-2 Class A and B requirements, as well as ASTM, ASME and EN weld standards. Because of its versatility, it can also be used for many other applications across the NDT industry.

Computed radiography starts here

Packed with innovative features to increase throughput, extend plate life and provide excellent image quality, the CRxVision is designed specifically for the inspection of welds. Because of its versatility, it can also be used for many other applications across the NDT industry.

A new innovative imaging plate design now provides the CRxVision imaging plates with more flexibility. This new design allows each imaging plate the ability to return to a flat state after being constantly bent around pipes for the inspection of welds. This feature also helps improve productivity by allowing the imaging plates to be easily extracted and reinserted into cassettes.

Highlights

Benefits

Benefits of the CRxVision

- Compliant to ISO 17636-2 Class A and B, ASME, ASTM and EN weld inspection standards

- The CRxVision has an extremely wide latitude eliminating the need for multiple gain settings

- Exposure times for welds are equal or better than existing film exposure times

- The scanner allows multiple imaging plates to be scanned simultaneously

- Imaging plates can be exposed in any type of cassette, then simply removed and inserted directly into the scanner

- A new innovative imaging plate design now provides the CRxVision imaging plates with more flexibility

Features

CRxVision: the versatile, new tabletop scanner

- Flexible accepting a wide range of sizes, shapes and classes of imaging plates

- Intuitive no gain setting or photomultiplier adjustments required when exposing various thicknesses

- Fast multiple plate scanning option: side-by-side and back-to-back with a flat transport path

- High Resolution new laser optics for profound reading and higher data extraction

- Extended Plate Life no mechanical handling of the imaging plate during scanning and erasing

- ASTM DICONDE Compliant fully compatible with Waygate Technologies existing Rhythm Software Platform

- Ambient Operation cover protects the imaging plate from light exposure

- Direct Laser Contact the laser beam is in direct contact with the imaging plate (no glass to obscure data collection)

Applications

Even though the CRxVision was designed for the inspection of welds, it also has the ability to cover a wide range of industrial radiography applications

- Weld inspection

- Erosion/Corrosion inspection (CUI, FAC, etc.)

- Castings (In-process and final)

- Valve positioning

- Concrete and Structure inspection

- Government (Arsenals, National Laboratories, Proving Grounds)

- Military (in-service aircraft, ships, etc.)

Technical Specifications of CRxVision

The CRxVision is providing the best combination in NDT for Resolution - SRb (image sharpness) – Scan cycle time and ISO Speed (dose efficiency or short exposure times). With its unique magnetic transport mechanism, the CRxVision does not touch the sensitive and image-critical phosphor layer, resulting in no loss of sharpness while maintaining the highest Signal-to-Noise ratio(SNR).

The CRxVision provides a 35-micron pixel pitch, which results in NDT’s best-in-class SRb of 40 micron. This means that the CRxVision is able to visualize up to 40 micron defects with the IPU2 Phosphor Image plate!

With a selected scan resolution of 35 micron, the outcome is 40-micron SRb. This means that the file size for such images is extremely efficient (small). Compared to other CR scanners in NDT where a selected pixel pith of 17 micron only results in 40-micron SRb, or a selected pixel pitch of 50 micron only results in 80 micron SRb, the file size of the CRxVision images is approximately 2-3 times smaller. This becomes an important benefit when sharing or archiving such large file sizes. Imagine storing 10.000 images 14x17”: either requiring 2,34Tb @ 35micron or 9,93Tb @ 25 micron.

The CRxVision is faster than most CR scanners in NDT. When scanning multiple Image Plates, the scancycle even reduces with factor 2 up to 5. Scanning multiple images simultaneously will either result in one large image or in multiple separated images supported by a smart ROI (Region of Interest) algorithm, depending on the user selection.

The CRxVision has the highest ISO speed in NDT. This is a measure for dose efficiency (or exposure time) for the combination IP plate and CR Scanner. The higher the ISO speed, the shorter the exposure dose required to fulfill the image quality parameters (SRb and SNR) as required in the different International Standards. The ISO speed is highly influenced by the internal components used in a CR scanner: optic module, light collector and PMT but also by the Phosphor Imaging plates. Using highest quality components and made and assembled in Germany, Waygate Technologies’ CRxVision scanners provide the highest quality and finest long-term stability. CRxVision’ s dose efficiency is between factor 3 and 15 better than other available CR scanners in NDT!

There is always a compromise between the size and weight of a CR scanner, and its long-term stability and high-quality image performance. The CRxVision is designed with weld quality in mind, providing highest scan resolution and best-in-class spatial resolution (SRb). Using high quality and weighty optic module and light collector, a finetuned distance between the Image Plate surface and the light collector and finally optimal transport mechanism components, the CRxVision is offering best-in-class image quality and long-term stability. Waygate Technologies however also offers the so-called Mobile Kit, equipped with heavy-duty shock absorbers, for installing the CR scanner inside a van or container, allowing usage of this high-quality device for mobile operation.