Revolutionizing Brewery Tank Inspections with the Ca-Zoom HD Camera

In the brewing industry, maintaining the integrity and cleanliness of stainless-steel fermentation tanks is essential for product quality and safety. However, traditional inspection methods—requiring confined space entry and scaffolding—pose significant safety risks and operational challenges. That’s why one brewery turned to Waygate Technologies for a smarter, safer solution using the Ca-Zoom HD remote visual inspection (RVI) system.

The Challenge: Confined Space Entry and Costly Scaffolding

The brewery needed to inspect its fermentation tanks using only a 3-inch nozzle located at the top of each vessel. Previously, inspections required human entry through a bottom manhole and the erection of internal scaffolding—both time-consuming and hazardous.

Their goals were clear:

- Eliminate confined space entry

- Avoid scaffolding and work at height

- Maintain high data quality for asset integrity and cleanliness

- Reduce downtime and inspection costs

The Solution: Ca-Zoom HD PTZ Inspection Camera

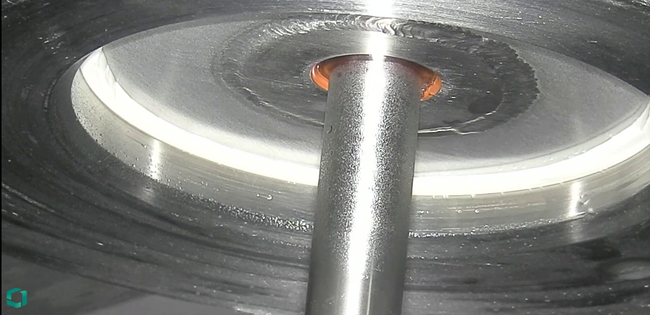

Waygate Technologies delivered a tailored solution using the Ca-Zoom HD camera, a PTZ (Pan-Tilt-Zoom) a "small" camera inspection camera designed for non-entry tank inspections and visual NDT in confined spaces.

Key Features:

- 10x Optical Zoom: Enables close-up inspection of welds, spray balls, and nozzles.

- Full HD Imaging: Provides high-definition visuals for accurate defect detection and cleanliness assessment.

- Pan-Tilt Functionality: Allows full internal coverage from a single access point.

- Fiber Pole Deployment: The camera was mounted on extendable poles and inserted through the 3-inch nozzle—no tank entry required.

- Cable-Lowering Option: Available for higher tanks or alternative configurations.

This setup allowed inspectors to remain safely outside the tank while accessing all critical internal areas.

The Results: Safer, Faster, and More Efficient Inspections

The entire inspection process—including setup—was completed in under an hour. The Ca-Zoom HD system enabled the brewery to:

- Avoid confined space entry and scaffolding

- Reduce administrative overhead (permits, safety planning, tank opening)

- Minimize downtime

- Collect high-quality data for routine preventative maintenance

The client confirmed that this approach not only met but exceeded their expectations, offering a viable alternative to traditional inspection methods.

Why This Matters for the Food and Beverage Industry

For breweries and other food-grade production facilities, the Ca-Zoom HD camera offers a powerful combination of:

- Improved safety

- Operational efficiency

- Cost savings

- Reliable asset integrity data

Whether you're inspecting fermentation tanks, pressure vessels, or internal spray systems, this remote visual inspection camera is a game-changer.