As the successor of the USIP 40 multi-channel flaw detector, the newly available Krautkrämer USIP|xs CV solves a growing need for easy, cost-effective integration. The improved multi-instrument architecture helps to optimize automation capabilities and provides more interfaces and flexibility. The USIP|xs CV can be integrated into any automated and semi-automated inspection system. With different T/R specifications and multitude of channel configurations, the instrument is scalable in performance as well as associated cost. As a result, it is well suited for a wide range of applications and system sized, such as Quality Assurance, Press Control and R&D.

Customer Benefits

Best automation capabilities

- Effective integration into automated systems of any complexity

- Integrated field bus connection enables for a single cable connection ton any PLC & significantly reduces wiring efforts when designing larger systems

Synergies of a scalable platform

- Perfectly fitted to the individual customer need

- Creates synergies concerning: technical infrastructures, Training/Integration know-how, Life cycle support, spare parts handling

Ease of use and operation

- Latest usability standards, vast integrated diagnostics features: reduced training, learning efforts, fast start up and maintenance

- Integrated box design superior to slot card design systems: widely reduces number of parts and interfaces, reduced probability of failure

- Plug and play - TÜV approved EMC and Safety: saves time, risk and cost compared to UT PCB suppliers

Benefits of the Krautkrämer USIP|xs CV

The plug-and-play instrument applies the latest usability standards and is equipped with a vast array of integrated diagnostic features. This allows a quick start-up and operation without excessive training of staff and learning efforts. The integrated box design of the USIP|xs CV makes the instrument extremely easy to maintain in comparison to slot card type electronics.

Industry-leading automation and integration capabilities allow for even the most complex systems to be built with less effort. Multiple interface standards – including field bus – make USIP|xs CV one of the best equipped instruments for effective integration into automated systems.

As one of the largest platforms of conventional ultrasonic instruments, the new Krautkrämer instrument offers UT performance and channel count perfectly fitted to individual inspection needs. In contrast to a “one-size-fits-all” solution, the USIP|xs CV creates synergies concerning technical infrastructure, instrument cost, and training and integration know-how, reducing the overall complexity of setting up and maintaining inspection systems.

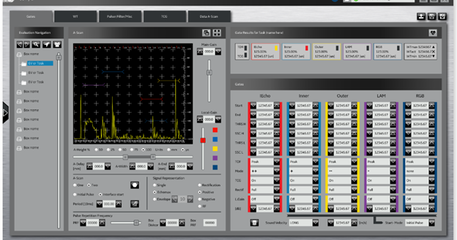

Software Highlights

- Fully refreshed GUI according to latest usability standards

- 5 gates per channel, up to 3 with its own amplifier -> flaw Evaluation and BWE by one channel

- Up to 8 parallel A-Scans

- All digital filters, pre-set and customizable

- TCG over the complete dynamic range; one curve for all probes or individual curves

- Remote Control for loading UT setups from L2 system

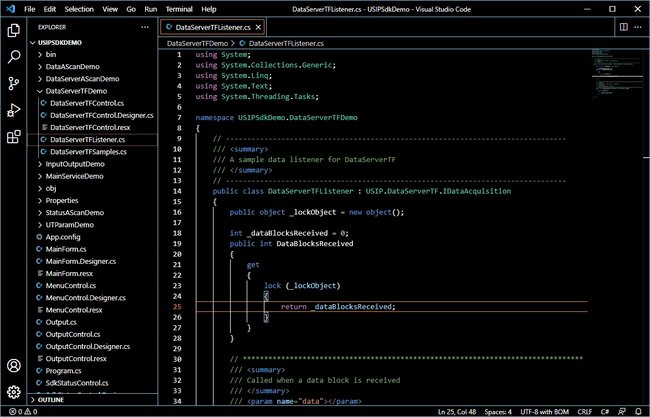

Create your own, customized Graphical User Interface (GUI) or integrate your GUI into another HMI environment. The instrument can be operated via the standard GUI and the customized GUI in parallel. All parameter changes are synchronized online through the SDK software.

Access all inspection raw data through the SDK:

- Collect gate data (amplitude, time of flight, gate events) for further processing in a customized inspection data display, evaluation, or recording

- Record digital Data-A-Scans in real time for a fully customized evaluation

Data A-Scan capabilities: Up to 4096 samples; configurable resolution per channel to reduce data size. Content per sample:

- 1x amplitude value (rectified amplitudes), resp. 2x (RF amplitudes)

- Encoder data x, y position (optional)

- Gate data: amplitude, time of flight (optional)

- Configurable amplitude resolution 16 bit or 24 bit (global parameter)

For eased communication within a system, the SDK unlocks additional digital I/O interfacing capabilities that can be used via the SDK-API, e.g., for PLC handshake, Inspection start/stop, Ready for testing, etc.:

- OUT: 3x via D-Sub, 12x via bus gateway; IN: 7x via D-Sub, 16x via bus gateway

- The SDK software supports C# / .ne

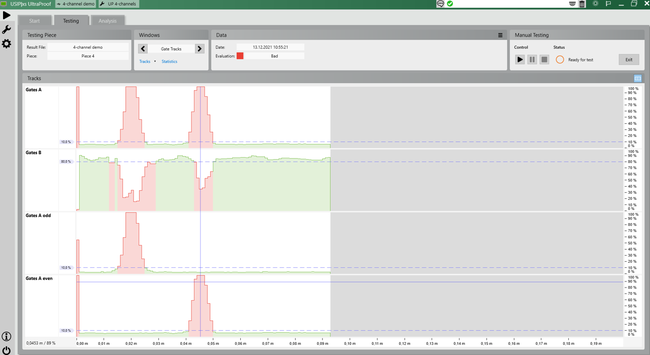

Digital strip chart recording software for installation on the USIP|xs system’s PC.

- Digital data interface to the USIP|xs single instrument or multi-instrument arrangements

- Records and displays the results of up to 160 gates per instrument

- Representation of event, amplitude and ToF [mm, inch] information

- All gate information can be grouped and assigned to suitable tracks according to the individual user requirements

- Strip chart display can be grouped into up to 8 configurable views containing up to 16 strip chart tracks each

- Max. 25000 length segments recordable per test piece (segment length configurable)

- Single piece or batch operation

- Start/pause/stop control via external test data release signals or manual

- “Ok” / “Not Ok” evaluation and interface signal

- Configurable statistics

- Report generator

- csv data export

- Viewer mode for review of stored inspection results