Image

Image

Eyebrow

Blog

How do I carry out flash radiography?

In this article:

- Flash Radiography Enables Non-Invasive Pipe Inspection: Flash (or pulse) radiography is used to assess the outer surface condition of insulated pipes without removing insulation, making it ideal for rapid, non-destructive testing.

- Soft Radiation and Short Exposure Times Are Key: The method uses relatively low-energy (soft) radiation and extremely short exposure durations—fractions of a second—to penetrate only the insulation and cladding.

- Pulsed Radiation Captures High-Speed Images: A burst of pulsed radiation is sufficient to expose specialized film-screen combinations like the F8 + NDT 1200, producing clear images of surface conditions.

- Minimal Safety Measures Required for Manual Use: Because of the low radiation dose and brief exposure time, flash radiography can often be performed manually without additional shielding or complex safety setups.

- Ideal for Detecting Surface-Level Anomalies: This technique is particularly effective for identifying corrosion or damage on the outer pipe wall beneath insulation, supporting preventive maintenance strategies.

Flash radiography or pulse radiography can be carried out when information is required about the condition of the outer surface of an insulated pipe, without having to remove the insulation.

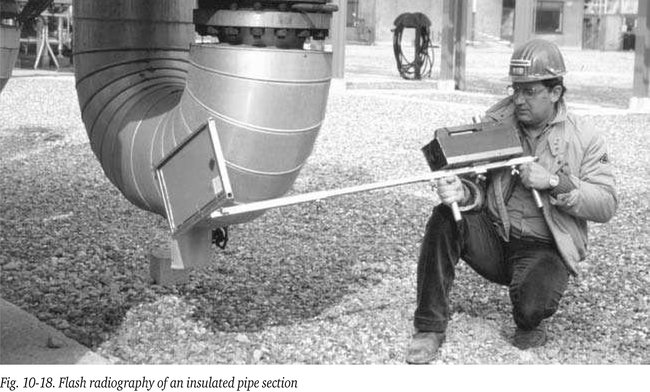

Figure 10-18 shows flash radiography in progress. Since only the aluminium cladding and insulation need to be penetrated, relatively soft radiation is applied, while exposure time is limited to only a fraction of a second. In that time sufficient “pulsed radiation” is generated to create an image on the superfast F8 + NDT 1200 (film+screen combination) see in the section about radiographic intensifying screens. It is safe to make radiographs manually without the need for additional safety arrangements.