Image

Image

Eyebrow

Blog

Determining Defect Depth Position in Radiographic Testing

In this article:

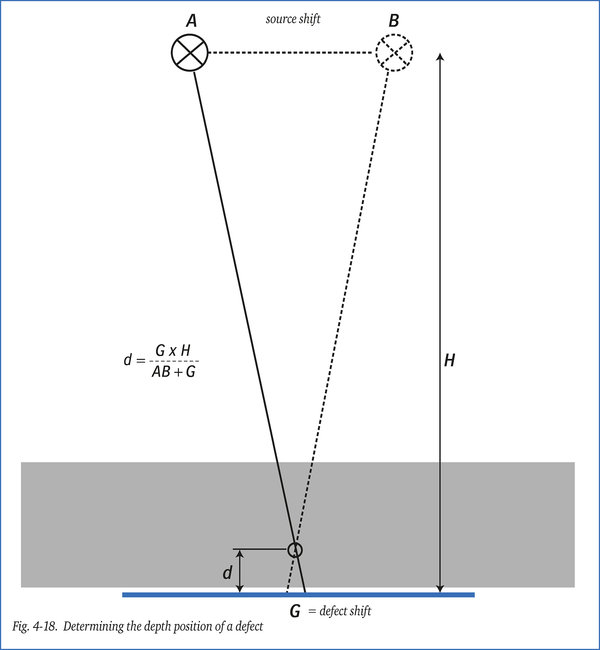

- Parallax Method Enables Accurate Defect Depth Measurement: The depth position of a defect is determined by exposing a radiograph from two different source positions and analyzing the shift in the defect’s image on the film.

- Single Film, Dual Exposure Technique Simplifies Setup: The method uses one film and two exposures from opposite angles, dividing the radiation dose equally between positions A and B to capture the necessary image displacement.

- Mathematical Formula Calculates Depth Precisely: The defect depth dd is calculated using the formula:

d=G×HAB+Gd=AB+GG×H

where GG is the image shift, ABAB is the source shift, and HH is the source-to-film distance. - Stereo-Radiography Offers an Alternative but Is Rarely Used: A more complex method involves using two separate films viewed via mirrors, but it is less common due to its complexity and equipment requirements.

- Ideal for Non-Destructive Testing in Industrial Applications: This radiographic technique is widely used in weld inspection, pipeline integrity checks, and structural evaluations where internal defect localization is critical.

The depth position (d) of a defect can be determined by the parallax-method, as shown in figure 4-18. The radiograph is exposed from two opposite angles. The required quantity of radiation is equally divided over positions A and B. Only one film is used. The shift in defect image on the film (G in mm) is a measure for the depth position; the shift of the source (A to B in mm) and the source-to-film distance (H in mm) are important data. The depth position is calculated with the formula: d = (GxH) / (AB+G).

Another, much more complex method of depth determination is stereo-radiography, by which two separate films are exposed which are viewed simultaneously via mirrors. However, this method is rarely used.