How do I set up a darkroom to process X-ray film?

In this article:

- Darkroom Location and Lightproofing Are Critical: The darkroom should be located near the exposure area but shielded from radiation. It must be completely lightproof, ideally using a labyrinth-style entrance to prevent light leaks

- Interior Design Enhances Functionality and Safety: Walls inside the darkroom should be painted in light colors for better visibility and cleanliness, while the entrance corridor should be matte black with a white guide stripe at eye level

- Use Safe Lighting for Film Handling: Orange-red (R1) or green (D7) darkroom lights are recommended. Light safety should be tested using pre-exposed film to ensure it doesn’t cause fogging or density shifts beyond 0.1

- Divide the Room into Wet and Dry Zones: The dry side is for handling unprocessed film and cassettes, while the wet side is for chemical processing. This separation helps prevent contamination and ensures workflow efficiency

- Test and Monitor Lighting Conditions Regularly: Perform safety tests by partially covering film under darkroom lights to verify exposure limits and ensure consistent image quality during processing

Processing and storage of X-ray films

Film developing is the process by which a latent image, see section 7.2, is converted into a visible image. The crystals in the emulsion - carriers of the silver traces forming the latent image - are transformed into metallic silver by selective reduction as a result of which the visible image is created. The development procedure must be carried out carefully to achieve this and guarantee successful archiving over a longer period. Manual developing is a laborious process that must be carried out meticulously in order to get the high quality results. For increased efficiency and uniform quality, X-ray films are more commonly processed processed automatically. The manual process is, however, still frequently applied. It will therefore be useful to describe manual processing in this chapter and so become familiar with the developing process.

How do I set up a darkroom to process X-ray film?

Entrance and colour

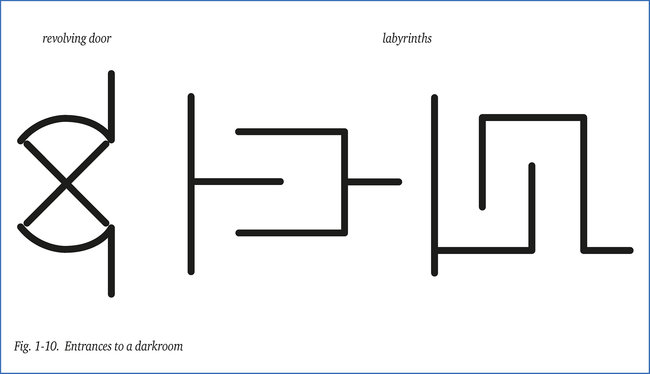

For practical reasons the darkroom needs to be as close as possible to the place where the exposures are made, although naturally out of reach of radiation. The darkroom needs to be completely lightproof, so the entrance must be a “light-trap” usually in the form of two doors, (one after the other), a revolving door or a labyrinth, see figure 1-10.

In practice the labyrinth is found to be the best arrangement, although it does take up a comparatively large space. The walls of the passage are painted matt black, and a white stripe about 10 cm wide running along its walls at eye-level is enough as a guide. Inside the darkroom itself, the walls should preferably be painted in a light colour; light walls reflect the little light there is and are easier to keep clean.

Darkroom lighting

X-ray films are best-processed in normal orange-red (R1) or green (D7) darkroom lights. The distance between film and darkroom lighting needs to be considered, depending on the sensitivity of the film and the duration of the development process.

The “light safety” of the darkroom lighting can be tested by covering half of a pre-exposed film (density 2) lengthways, leave it for 5 minutes and then process it as usual. The difference in density may not exceed 0.1.

Another method is to place an unexposed film on the workbench and cover part of it up with a sheet of cardboard, which is then gradually removed so as to produce a series of different exposures. By developing the film in the usual way, it will then be possible to see how “safe” the light is, and how long a film can be exposed to it before it exceeds the maximum acceptable difference in density of 0.1.

What are recommendations for the dark room to process X-ray film?

The darkroom should preferably be divided into a dry side and a wet side. The dry side will be used for loading and emptying cassettes, fitting films into developing frames and so on - in short, for all the work that does not allow dampness.

On the wet side, the films will be processed in the various tanks of chemical solution. For efficient working, and to ensure uniform quality, there should be automatic control of the temperature of the solutions.

In processing tanks used in the manual process, films are held vertically in their frames. These tanks can be made of stainless steel or plastic. The dimensions of the tank must be suited to the size and number of films to be processed. There must be a space of at least 1.5 cm between films. The top edge of the films must be approx. 2 cm below the surface of the solution.

The wet side of the darkroom will have five tanks, arranged in the following sequence:

- developer tank

- stopbath or rinse tank

- fixer tank

- final wash tank

- tank for wetting solution