Types of transport- and exposure containers?

In this article:

- Transport and Exposure Containers Ensure Radiation Safety: These containers are designed to shield continuously emitting radioactive sources during transport and use, complying with strict international safety regulations

- Shielding Materials Include Lead, Tungsten, and Depleted Uranium: Lead is common, but newer sintered tungsten (97%) and depleted uranium offer higher radiation absorption in more compact designs—though uranium use is restricted in some countries

- Exposure Containers Must Be Fail-Safe and Durable: Also known as “cameras,” these containers must be impact-resistant, waterproof, and maintain shielding integrity even in extreme conditions like fire

- Two Common Designs: Rotating Cylinder and S-Channel: These mechanisms safely store and deploy the radioactive source, with the S-channel often paired with a flexible cable system (Teleflex) for remote operation

- Remote Handling Enhances Operator Safety: Flexible metal hoses and cables allow the source to be positioned several meters away from the container, minimizing radiation exposure to personnel

What are the types of transport- and exposure containers in industrial radiography?

Transportation and handling of sealed sources are subject to strict international safety

regulations, as a source is continuously emitting radiation in all directions, in contrast to an

X-ray tube which can be switched off. During transportation and use the source must be

surrounded by a volume of radiation absorbing material, which in turn is encapsulated in

a container. The level of radioactivity at the outside surface of the container shall not

exceed the legally established maximum limit.

Like the transport container, the exposure container needs to be robust and must function

safely at all times. The exposure container, also called camera, must be fail-safe and water-

and dirt proof. It must also not be effected by impact. Moreover, if the radiation-absorbing

material, for example lead, melts (in a fire) the radiation absorbing qualities must not be

lost. This requires a casing made of a material with a high melting point, for example steel.

Besides lead, increasingly a new sintered material with very high tungsten content (97%)

is used as shielding material. This material is easily worked and finished and not prone to

melting.

Also greatly depleted uranium (with the highest radiation absorption) is used for shielding,

resulting in very compact exposure containers. A disadvantage of this material, however, is that it has a certain minimal radioactivity, which is reason that in some countries the use of

depleted uranium is not allowed.

Regardless of the shielding material used, all containers have a considerable weight in

common.

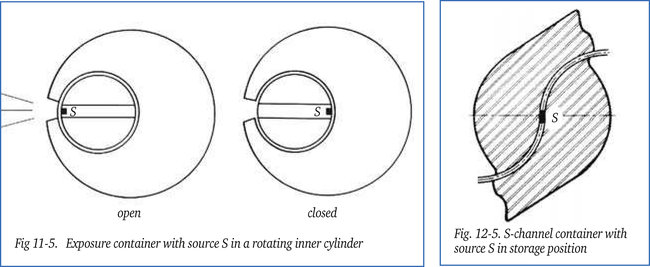

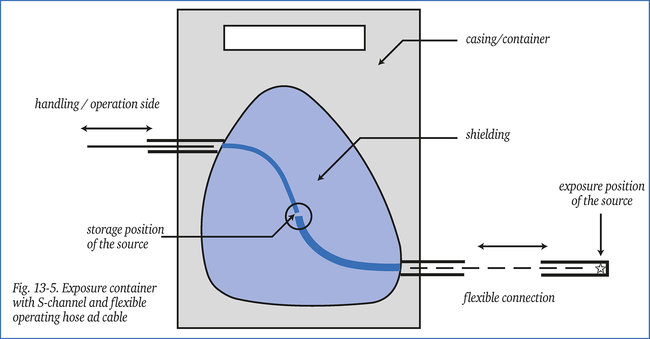

There are several solutions to the problem of safely storing a source on the one hand, and

of putting it in a simple but absolutely safe manner in its radiation position on the other

hand. Two regularly used constructions for this purpose are: source S is situated in a rota-

ting cylinder, as shown in figure 11-5, or in an S-channel container as shown in figure 12-5.

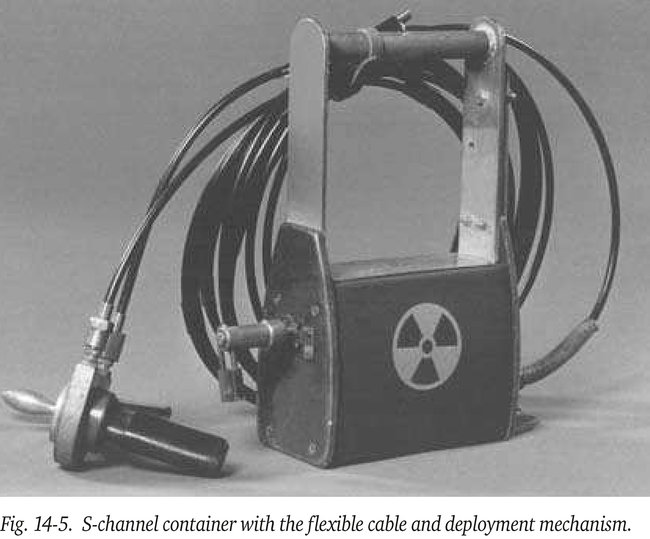

The S-channel container is usually provided with a means to move the source out from a

distance (after all, distance is the safest protection from radiation). This may be done by

means of a flexible cable in a hose (Teleflex design) as shown in figures 13-5 and 14-5.

With this construction it is possible to extend the flexible hose in such a way that the source

can safely be moved several metres out of the container to the most favourable exposure

position.

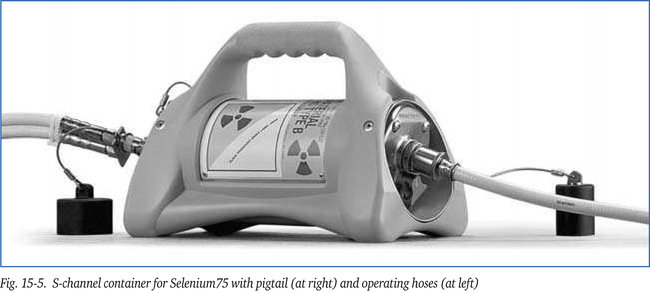

Figure 14-5 shows an S-channel container with a flexible (metal) hose and cable in rolled up (transport) position. Figure 15-5 shows a more recent (2006) S-channel Selenium75 container with operation hoses and pigtail. Selenium75 radio-isotope is becoming popular since new

production (enrichment) methods resulted in a much better k-factor. Thus for a certain activity (source strength) a much smaller source size (focus) is achieved. This results in a better/sharper image quality than could be achieved with the old Selenium75 production method. Due to its average energy level of 320 kV, Selenium75 increasingly replaces X-ray

equipment for a thickness range from 5 mm to 30 mm of steel. This eliminates the need for

electric power, very attractive in the field for reasons of electrical safety and more

convenient at remote- or work locations with difficult access (high, deep, offshore,

refineries, etc). Last but not least, a Selenium container is of much lower weigth than

needed for an Iridium192 container with the same source strength.

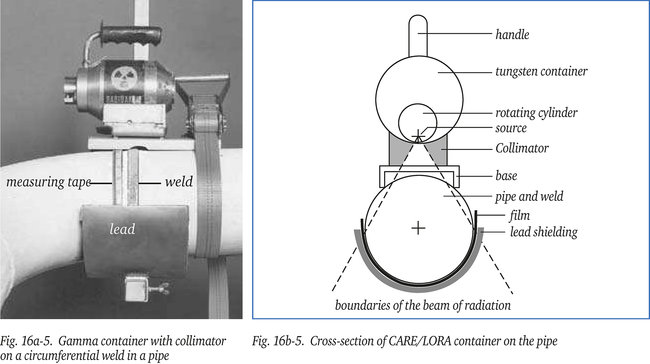

To enable radiography on work sites with (many) people in the vicinity, for example on offshore installations or in assembly halls, containers with rotating cylinders and collimators were developed so that only the beam of radiation required for the radiograph is emitted. The remainder of radiation is absorbed by the collimator material which allows people to work safely at a distance of a few metres while radiography is in progress. Such containers with collimators are known by the name of “CARE” (Confined Area Radiation Equipment) or “LORA” (Low Radiation) equipment.

Without collimating the minimum safety distance is considerably more than 10 metres (in all directions!).

Such containers with collimators are particularly suitable for frequent and identical repetitive NDT work, for example radiographic testing of welds in pipes of < 300 mm diameter. Figure 16a-5 shows such a special container with collimator set up for a double wall radiograph. The cross-section drawing of figure 16b-5 shows the boundaries of the beam of radiation. For bigger focus-to-film distances, longer collimators are used to restrict the beam of radiation.

This type of container is suitable for Iridium sources up to 1000 GBq and weighs “only” approx. 20 kg.

A sealed radioactive source (capsule) might start to leak and become an open source as a result of corrosion, mechanical damage, chemical reactions, fire, explosion etc. Regular mandatory “wipe-tests” by specialists serve to detect leakage at an early stage.