Image

Image

Eyebrow

Blog

What influcences the speed of film in radiography?

In this article:

- Film Speed in Radiography Reflects Exposure Efficiency: Film speed refers to the amount of radiation exposure required to achieve a specific image density (typically 2.0 above base and fog), with faster films needing less exposure

- No Universal Speed Ratings in Industrial Radiography: Unlike consumer photography, industrial radiographic films do not use standardized speed ratings like ASA or DIN; instead, speed is determined through exposure-to-density testing

- Processing Conditions Significantly Impact Speed: Factors such as developer type, temperature, and processing time directly influence film sensitivity and must be controlled for consistent results

- Film Type and Emulsion Characteristics Matter: Different film types (e.g., Agfa D2 vs. D8) have varying grain structures and emulsion thicknesses, which affect their relative speed and image resolution

- Characteristic Curves Help Visualize Film Performance: The density curve (or H&D curve) illustrates how film responds to exposure, helping technicians select the right film and settings for optimal radiographic quality

In radiography the relationship between exposure (in C/kg) and resulting density is commonly referred to as film speed. Other than in normal photography where film speed is indicated by a DIN or ASA number, films for industrial radiography do not carry an internationally recognized speed number.

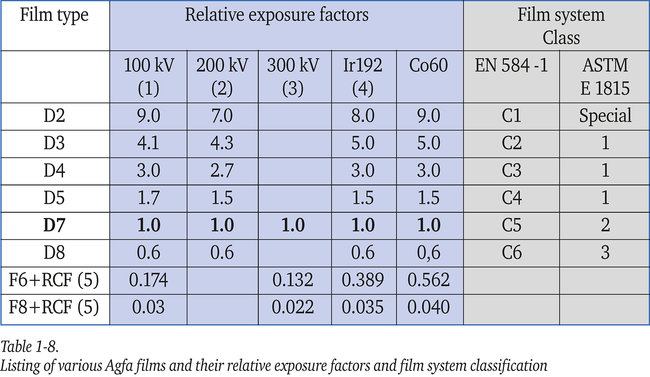

The generally accepted method of measuring the film speed of radiographic films is to measure the exposure required to achieve a density of 2.0 above base and fog, using a specific processing technique. The various relative exposure values are shown in table 1-8.

What does the characteristic curve or density curve indicate?