Which chemicals do I need to process X-ray film?

In this article:

- X-ray Film Processing Requires Developer and Fixer Solutions: The two essential chemicals are a developer (e.g., STRUCTURIX G128 or G135) and a fixer (e.g., STRUCTURIX G328), both typically supplied as liquid concentrates for manual or automatic processing.

- Developer Preparation Depends on Application Type: For manual processing, G128 is diluted at a 1:4 ratio with water; for replenishment, a 1:3 ratio is used. Automatic systems use G135 developer with a 100-second cycle at 28°C

- Fixer Is Prepared Similarly to Developer: STRUCTURIX G328 fixer is also diluted with water and used to remove unexposed silver halides from the film, ensuring image permanence and clarity

- Consistent Temperature and Agitation Are Critical: Optimal development occurs at 20°C for manual processing (5 minutes) and 28°C for automatic systems. Films must be agitated during the first 30 seconds to prevent air bubbles and streaks

- Proper Chemical Handling Ensures Image Quality and Safety: Each chemical must be mixed in separate, dedicated containers, and the darkroom environment should be well-ventilated to avoid fume buildup and maintain safe working conditions

Making-up processing solutions

Nowadays, chemicals are supplied as a liquid concentrate, suitable for the particular

type of film used.

The processing solutions can be prepared either directly in the tanks or in plastic buc-

kets. In the latter case each type of solution must be prepared in a separate bucket,

which is never used for other chemicals.

Developer

Development fog, graininess and contrast are dependent on the type of developer,

which is preferably made up to suit the film used.

If a concentrated manual developer is used, for example G128 made by Agfa, and the

developer tank has a capacity of, say, 25 litres, then all to do is pour 5 litres of the con-

centrated developer into the tank and add 20 litres of water (ratio 1 part of concentra-

te to 4 parts of water). G128 developer is also used as a replenisher, in which case 3

parts of water are added to 1 part of concentrate.

Fixer

Fixer too is supplied as a concentrated liquid (G328). The same instructions as for pre-

paring developer apply here.

Developing times and bath temperatures

The film is clipped on or slipped into a frame, depending on the type of frame, and hung

in the developer tank. As soon as the film is submerged in the developer, the darkroom

timer is set for the required number of minutes. The optimal developing time is the time

at which the most favourable “contrast to fog ratio” is achieved. Minor deviations from

the correct exposure time may be compensated by adjusting the developing time.

The recommended developing time for Agfa films in G128- manual developer is

5 minutes at 20°C. In the automatic process using G135 developer, the developing time

is 100 seconds at 28°C. Deviating from the recommended developing times and

temperatures will almost always lead to reduced image quality (e.g. increased coarse-

graininess).

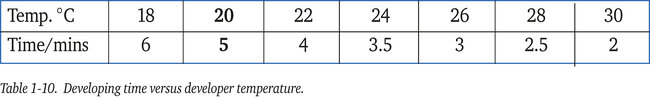

Raising the tank temperature will speed up the development process as table 1-10

shows, but the developer will oxidise more rapidly. Should it not be possible to achieve

a bath temperature of 20°C, the following developing times can be used at the

temperatures as indicated in table 1-10. This applies to all D-type films.

The temperature of the developer shall never be less than 10°C, but is preferably

higher than 18°C to obtain optimal image contrast. It is best to always maintain the

same developing conditions, so that the exposure technique can be matched to these

and uniform results obtained.

Film agitation

To prevent air bubbles from forming on the surface of the emulsion (which will cause

spots on the finished radiographs), and to make sure that the developer penetrates all

areas of the emulsion evenly, the films should be kept moving during their first 30

seconds in the developer. After that, it is recommended to move the film from time to

time to prevent film faults such as lines or streaks.

Replenishing

Up to 400 ml of liquid per square meter of film processed may be carried over to the next

tank. When developing frames used it is, therefore, preferable to hold the film

2-3 seconds over the developer tank to drip.

After each square meter of film developed, 600 ml of replenisher must be added to the

bath regardless of the quantity of developer lost from the tank. Up to about 4 litres of

replenisher can be added in this way, for every litre of the original developer in the tank.

The solution must be discarded and replaced with fresh developer when the total

quantity of replenisher added is three times the original total contents, but in any case

after eight weeks, irrespective of the number of X-ray films processed.

Stopbath

Before transferring the developed film to the fixer tank, it is placed in a stopbath

(consisting of 30 ml glacial acetic acid to 1 litre of water) for 30 seconds to prevent the

fixer solution from being neutralized too rapidly by the developer, and stripes or

dichroitic fog from forming on the film.

If a film is not passed through a stopbath, it must be rinsed in running water for a few

minutes immediately after leaving the developer.

Fixing

Fixing renders the image formed during development permanent, by removing unde-

veloped silver halide salts from the emulsion. When the film is taken from the stopbath

it still has a milky appearance; this changes in the fixer and the light areas of the film

become transparent.

As a rule the film is left in the fixer twice as long as it takes to “clear” or become trans-

parent. Fixing time (in a fresh solution approx. 3 minutes) is twice the clearing time

(1.5 min.). As soon as it takes double that time to “clear” a film in G328 fixer solution

at 20°C, it must be replaced.

For every liter of solution in the fixing tank, a square meter of film can be treated.

Films have to be kept moving during the first 30 seconds in the fixing bath.

Final wash

The final wash is intended to remove to remove the residual fixer and the soluble silver

compounds left behind in the emulsion, which if not flushed out, would reduce film

shelf life. Washing should preferably be done with running water, ensuring that all

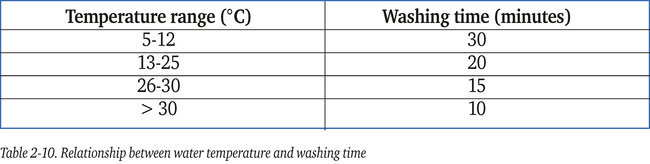

parts of the film are reached by fresh water. The duration of the final wash depends on

the temperature of the water. See table 2-10. Temperatures over 25°C must be avoided.

Drying in the drying cabinet

When the film is taken out of the water, the water on the film, as a result of its surface

tension, runs together to form droplets of varying size. The film will, therefore, dry une-

venly, causing “drying marks”. For this reason it is advisable to immerse the films in a

solution of 5-10 ml wetting agent to each litre of water. Wetting agent reduces the sur-

face tension of the water so that, after the film has drained, the surface will be evenly

wetted and will dry evenly with no risk of marks. Films should be hung to drain for

about 2 minutes before they are placed in the drying cabinet.

Drying should preferably be done in a drying cabinet, or alternatively in a dry and dust

free room. No drops of water must be allowed to fall on films that are already drying, as

this will cause marks. Wet films should, therefore, always be hung below already

drying films.

Drying time will depend on temperature, air circulation and relative humidity of the air

in the cabinet. Films will dry more quickly when they have first been put into a wetting

agent.

Before a film is taken out of the drying cabinet, it must be checked that the corners and

edges of the film are thoroughly dry. Air temperatures above 40°C should be avoided as

this may cause ugly drying marks. There must be free circulation of air between the

films in a cabinet; if they cannot dry evenly on both sides, they may curl or distort.

Roller dryers

Industrial dryers can be used to dry films quickly and uniformly after washing.

This mechanised drying process only takes minutes. Dryers and chemicals should

preferably be matched. There are compact roller dryers on the market which are

capable of developing approx. 15 cm of film per minute and take up far less space than

a drying cabinet.

Use of the characteristic (density) curve with an exposure chart