Corrosion Scanning with Handheld DM Array Probe

Inspection of internal corrosion and erosive wall loss

In this article:

- Handheld DM Array Probe Revolutionizes Corrosion Scanning: Waygate Technologies introduced a handheld DM Array Probe to replace traditional point-by-point ultrasonic inspections, enabling full-area corrosion mapping for more accurate asset evaluation

- 100% Area Coverage for Critical Assets: The solution allows complete scanning of suspect areas on piping, storage tanks, and other infrastructure, identifying true minimum wall thickness and detecting random pitting or erosion

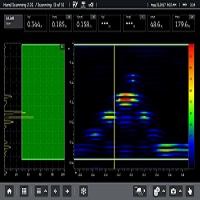

- Enhanced Visualization and Data Accuracy: The probe delivers high-resolution imaging and real-time visual confirmation of wall loss, improving inspection reliability and decision-making

- Improved Efficiency Over Legacy Methods: Compared to grid-based point measurements, the handheld array significantly reduces inspection time while increasing the probability of flaw detection

- Ideal for Internal Corrosion and Erosive Wear: Designed for industrial environments, the system supports proactive maintenance strategies by providing detailed, actionable insights into asset integrity

Customer Need

Historically, ultrasonic corrosion surveys have been conducted with point measurement probes taking a grid of points over a given area. Unfortunately, this method provides an incomplete picture which makes it likely that the true minimum of a given inspection area is never detected.

Application

Inspection of assets subject to internal corrosion and erosive wall loss such as piping, storage tanks, and other critical assets; requiring visual display and confirmation of remaining wall thickness.

Customer Solution

By using Waygate Technologies's handheld DM Array Probe, the suspect area can be 100% scanned to locate the true minimum thicknesses--as well as any random pitting or damage that may exist. This provides a much more accurate assessment.

Product Features

• Customizable Palm Scanner App on the Mentor UT provides a guided workflow to standardize and reduce time for calibration and set-up of inspection

• Touch screen operation for fast and easy interrogation

of suspect areas

• DM Array probe optimized for pitting corrosion detection

- Modular probe design for cost effective replacement

• Mentor UT Phased Array Flaw Detector - P/N 100N3883

• DM Acoustic Module (5 MHZ x 1.5 mm) - P/N DMARRAY_MOD1

• Probe Cable (3 m; Side Exit) - P/N DMCABLE_3M_RT