Small Diameter Circumferential Weld Inspection

Weld assessment of difficult-to-access, small diameter pipes

In this article:

- Precision Inspection for Small-Diameter Welds: Waygate Technologies developed a solution for inspecting circumferential butt welds in small-diameter pipes (1.5”–3.5”), commonly found in boilers and other critical infrastructure

- PALM Scanner Enhances Accuracy and Accessibility: The PALM scanner, paired with phased array ultrasonic testing (PAUT), delivers high-resolution defect detection with a compact, lightweight design that fits into gaps as narrow as 12 mm

- Optimized Ultrasonic Beam Focus: The system uses laterally focused array probes with concave curvature to improve lateral resolution and surface focus, increasing the probability of defect detection

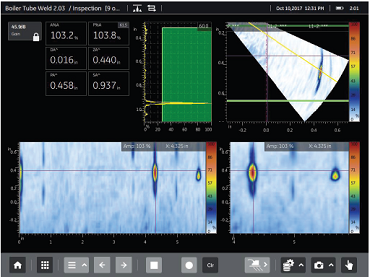

- Integrated Workflow with Mentor UT: The Mentor UT flaw detector and PALM scanner app streamline calibration, setup, and data analysis, reducing inspection time and standardizing results

- Versatile and Efficient for Industrial Use: Designed for both ferromagnetic and non-ferromagnetic pipes, the system supports fast, reliable inspections with minimal disruption to operations

Circumferential butt welds are found in various structures including small diameter tubes in boilers. Experts inspect the tubes to locate defects which could result in the failure of a component, possibly inducing a human or environmental hazard. When NDT inspection of circumferential butt welds are performed manually, it is difficult to meet the required standards on safety, measurement precision, reliability, and quality data management.

New or repaired welds are usually inspected by radiography however the technology requires evacuation of the workers on site and considerable time for developing the radiographic films.

Weld assessment of difficult-to-access, small diameter pipes.

BHGE Inspection Technologies field-proven PALM scanners can inspect pipes of diameters from 1.5” up to 3.5”. The scanners are easily adaptable with various wedges and phased array probes to meet inspection procedures regardless of tube thickness, material or acceptance criteria.

The PALM scanner uses laterally focused array probes with concave curvature in elevation; the probe design optimizes the ultrasonic beam focus on the surface and increases lateral defect resolution compared to unfocused probes.The wedges are designed with integrated irrigation channels for consistent couplant feed and all the curvatures are crafted to fit the PALM scanner.

Product Features

- Palm Scanner App on the Mentor UT provides a guided workflow to standardize and reduce time for calibration and set-up of inspection

- Touch screen operation for fast & easy interrogation of suspect areas

- Compact, rigid and lightweight with easy access for gaps as narrow as 12 mm (0.47 inches)

- Optimum spring-loaded open clamp system with no axial slip

- Fast and easy movement between measurements

- Suitable for ferromagnetic and non-ferromagnetic pipes

- Mentor UT Phased Array Flaw Detector - P/N 100N3883

- PALM 50 Package for pipe diameter 1.5” to 2.0” (38 mm to 50 mm) - P/N 0600392

- PALM 64 Package for pipe diameter 2.0” to 2.5” (50 mm to 64 mm) - P/N 0600393

- PALM 90 Package for pipe diameter 2.5” to 3.5” (64 mm to 90 mm) - P/N 0600394