The potential hidden in battery production that drive this industry

In this article:

- Industrial CT and X-ray inspection technologies are critical for scaling battery production while maintaining high quality, especially in electric vehicle (EV) manufacturing.

- Waygate Technologies’ Phoenix Speed|scan HD system enables real-time, automated inspection of battery cells for defects like anode overhang and weld quality, reducing scrap and increasing throughput.

- Advanced inspection solutions support all major battery cell formats—cylindrical, prismatic, and pouch—ensuring consistent quality across diverse production lines.

- Performance-level inspections, including microCT, nanoCT®, and electron microscopy, allow for ultra-detailed analysis of battery structures, vital for R&D and high-stakes applications like aerospace.

- Integrating inspection into production lines enhances safety, efficiency, and competitiveness, making it a cornerstone of modern battery gigafactories and the future of electrified mobility.

Day by day, electrification is gaining importance in our everyday lives. As a result, batteries are becoming omnipresent and greater quantities need to be produced. For battery manufacturers, scaling up production volumes while maintaining high quality is a huge challenge. X-ray and CT inspection solutions by Waygate Technologies address these challenges and can lead to major competitive advantages.

One very significant growth driver for the battery industry are electric vehicles or EVs. Let’s take a closer look into the potential hidden in the production of the batteries which literally drive this industry.

Batteries used in EVs today can have a storage capacity of up to 100 kWh, can be charged within 30 minutes and are created for up to 1,000 loading cycles throughout their lifetime – all while being remarkably robust.

Regardless of type, these batteries are all produced during complex processes in so-called Gigafactories. This is where advanced industrial inspection can notably contribute to improve factory productivity and battery quality. Waygate Technologies offers solutions for all common cell types: cylindrical, prismatic and pouch.

To maintain stable production processes, every produced cell can be scanned by our CT inspection solution Phoenix Speedscan HD for common fault patterns such as anode overhang.

X-ray and CT are crucial for this safety relevant inspection and should be seamlessly integrated into the manufacturing process.

Another important check inspects the weld quality of tabs, current collectors, poles and foil or case. Thanks to superior image quality and automation, the Speed|scan HD brings offline tasks to the production line.

With these checks, advanced industrial inspection becomes a key technology for the safe and efficient electrification of the mobility sector worldwide: It helps to reduce scrap and to increase the output of battery cells which are subsequently delivered to EV manufacturers for final assembly - all while maintaining the highest production quality possible.

Performance Inspections to take battery technology to new levels

Some battery applications for example in aviation or space exploration or in research and development require even more detailed – so-called performance – inspections. Here, taking an even closer look becomes pivotal in successfully performing inspection tasks.

Waygate Technologies’ Phoenix V|tome|x M CT scanner is the ideal solution for industrial or scientific microCT and nanoCT® tasks.

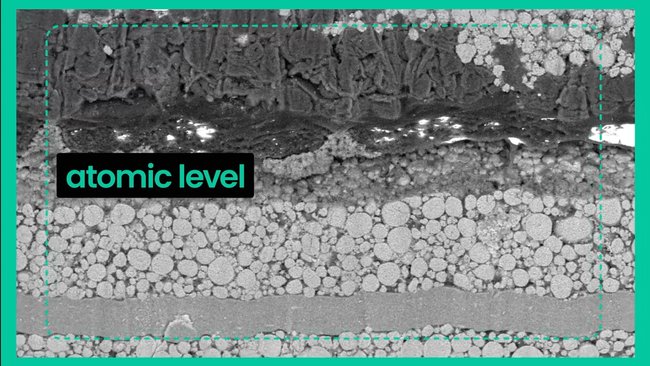

And with electron microscopy which takes analyses down to the atomic level, even the tiniest structures found in batteries are now subject to close inspection.

Illustration of V|tome|x M and Microscopy image at atomic level

Creating the future of mobility with battery inspection

Industrial X-ray and CT can accompany many critical steps within the production process of modern EV batteries. In doing so, it plays a vital part in making the future of mobility more sustainable. As a reliable and experienced partner for industry-leading corporations, Waygate Technologies is ready to help solve any inspection challenge which battery manufacturers may encounter along the way.

Principles of CT Operation: What is industrial cone beam computed tomography?