What skills do I need to obtain as a film-interpreter?

In this article:

- Thorough Knowledge of Manufacturing Processes Is Essential: A film interpreter must understand how the inspected object is made, as different processes (e.g., casting vs. welding) produce distinct types of defects.

- Familiarity with Defect Types Across Materials and Methods: Interpreters must recognize characteristic flaws specific to various welding techniques and casting methods to accurately evaluate radiographic images.

- Training and Standards Vary by Region and Industry: While formal training programs for film interpretation are not yet standardized globally, many follow ASNT (American Society for Nondestructive Testing) or similar qualification frameworks.

- Reference Materials and Visual Libraries Support Learning: Tools like the IIW weld defect collection and ASTM casting defect sets are commonly used alongside instructor-curated radiograph examples for hands-on training.

- Viewing Conditions and Equipment Must Meet Professional Standards: Proper lighting, calibrated viewing devices, and controlled environments are critical to ensure accurate and consistent film interpretation.

What skills do I need to obtain as a film-interpreter?

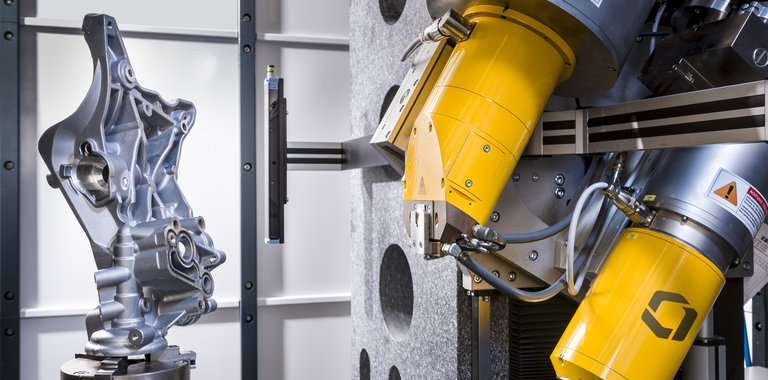

Apart from the requirements regarding “viewing conditions” and “viewing equipment” the film-interpreter (film viewer) shall have thorough knowledge of the manufacturing process of the object being examined and of any defects it may contain. The type of defects that may occur in castings, obviously, differs from those in welded constructions. Different welding processes have their own characteristic defects which the film interpreter must know to be able to interpret the radiograph.

To become a qualified NDT operator, various training courses, course materials and leaflets specifying the requirements they need to comply with, exist. The European NDT industry conforms to the qualification standards of the American ASNT organisation.

So far, a training programme for film-interpreter has not been established in similar fashion. Textbooks for example are not uniform. Sometimes, the IIW-weld defect reference collection is used, beside which the instructor usually has his own collection of typical examples, supplemented with process-specific radiographs.

ASTM has a reference set of defects in castings available.

There are incidental initiatives to introduce classification of film-interpreters by level, in a system comparable to the qualification of NDT-personnel. Some countries have already implemented such a system.