Waygate launches Krautkrämer ROWA™ Ux 400 mini

In this article:

- Waygate Technologies Introduces ROWA™ UX 400 mini for Small-Diameter Metal Bars: The new phased array ultrasonic testing (PAUT) system is designed for inspecting metal bars and wires as small as 6 mm in diameter, addressing growing demands in automotive and precision manufacturing

- Compact, Maintenance-Free Design Boosts Uptime: Unlike traditional rotary systems, the ROWA™ UX 400 mini features stationary phased array probes mounted on a stainless steel block—eliminating moving parts and reducing maintenance needs

- Software-Driven Setup Enhances Flexibility: Operators can adjust probe settings electronically without manual changes to incidence angles or water paths, streamlining setup and improving inspection consistency

- Optimized for High-Strength, Lightweight Materials: The system supports the inspection of pre-materials used in lightweight, high-strength steel components, making it ideal for automotive, mechanical engineering, and medical sectors

- Built on 20+ Years of Phased Array Expertise: The UX 400 mini combines decades of ultrasonic testing innovation with proven ROWA system reliability, offering a robust, low-cost solution for high-throughput environments

Waygate Technologies launches its first phased array ultrasonic testing solution for small diameter metal bars and wire:

Krautkrämer ROWA™ Ux 400 mini

Huerth, Germany, March 30, 2021. Waygate Technologies, a Baker Hughes business (formerly GE Inspection Technologies) and a world leader in industrial non-destructive testing (NDT) solutions, today announced the market introduction of its first phased array ultrasonic testing machine for small diameter metal bars and wire in the 6-25mm diameter range. By driving the inspectable diameter down by 40%, the new Krautkrämer ROWA™ Ux 400 mini meets the increasing demand for the inspection of pre-material for ever more lightweight, high-strength steel parts. The new inspection solution specifically targets the automotive industry but similarly suits the requirements for the inspection of steel bars and other materials for the mechanical engineering, power generation, chemicals, and medical sectors.

The ROWA™ Ux 400 mini combines 20+ years of experience in phased array technology with Waygate Technologies’ robust, low-maintenance design of the ROWA inspection system which is trusted by manufacturers, certifiers, and auditors alike for proven reliability and detection performance.

Less maintenance, more productivity

The ROWA™ Ux 400 mini features the most simplified yet robust test mechanics on the market which allow for an easy handling and a maximum of uptime while still safeguarding consistent quality. In contrast to conventional mechanical rotary systems, the new solution relies on industry-leading phased array technology for more efficient testing of metal bars.

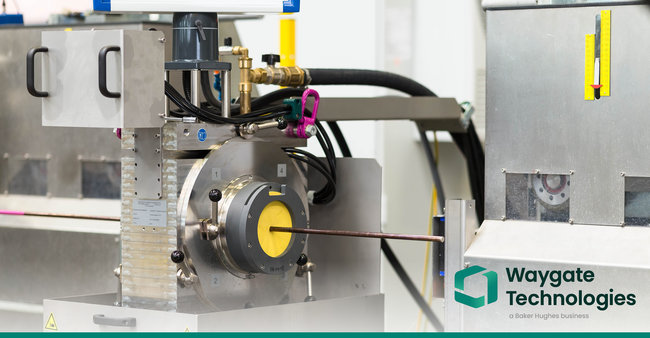

The ultrasonic testing device employs a simplistic design with the phased array probes securely mounted on a stationary stainless steel block and without any rotating parts like probe holder mechanisms, seals, and bearings which typically need regular manual adjustment, care, and service.

The stationary mounted phased array probes can easily be set up for each diameter via software and electronics, without the need to set the incidence angle and change the water path of probes or probe modules manually.

The ROWA™ Ux 400 mini thereby not only increases productivity and reduces operational costs through ease-of-use and high uptimes, it also requires lower maintenance and costs for spare parts. It is also superior to other phased array inspection solutions for bars and wire available on the market due to its extremely compact and unique design.

“We are excited that we can now offer our unique high-end ROWA™ Ux solution also for much smaller metal bars with a diameter starting from 6mm,” said Stephan Schmitz, Product Manager for Ultrasonic Testing Machines at Waygate Technologies. “Especially the automotive industry and its suppliers are constantly facing pressure to save costs and streamline production processes. Our ROWA™UX 400 mini is addressing this challenge for them and other manufacturing sectors while still delivering our long-established NDT technology that is trusted by our customers and end users.”

The new ROWA™ Ux 400 mini is now available globally. It is the latest addition to the robust Krautkrämer ROWATM Ux product series that provides industry-leading metal bar inspection at a low total cost per inspected part. While the new ROWA™ Ux 400 mini allows for the inspection of small diameter metal bars, the ROWA™ Ux can inspect round metal bars up to 260mm in diameter and square or hexagonal bars with a width up to 50mm. Learn more and contact Waygate Technologies:

- Waygate Technologies metal bar inspection