Exploring Diverse Special Applications of Radiography in NDT

In this article:

- Effective Focal Spot Size Is Critical for Image Sharpness: The effective focal spot of an X-ray tube directly influences radiographic resolution and is a key parameter in non-destructive testing (NDT) image quality.

- EN 12543-1 Standard Defines a Precision Measurement Method: This method uses a scintillation counter and double collimator with a 10 μm aperture to scan the X-ray beam, generating a 3D intensity profile to determine the focal spot size—ideal for spots <0.2 mm.

- Pinhole (Camera Obscura) Method Remains Widely Used: A traditional and simpler approach involves projecting the X-ray focus through a small hole in a lead or tungsten plate onto film, then measuring the spot size with a magnifier.

- Film-Based Methods Yield Slightly Smaller Spot Sizes: While still compliant with EN standards, the pinhole method may produce marginally smaller focal spot measurements compared to the EN 12543-1 technique.

- Panoramic Tube Spot Measurement Is More Complex: For panoramic X-ray tubes, direct focal spot measurement is difficult; instead, radiographic image quality indicators (IQIs) are used to verify compliance with resolution standards.

There are many special applications of radiography in NDT. This chapter describes a limited number of different examples to illustrate this diversity. Apart from the use of radiation in image forming radiography, it is also used in, for instance, measuring instruments such as metal alloy analysing instruments (Positive Material Identification, PMI). This type of non-image forming instruments and applications are outside the sphere of this book.

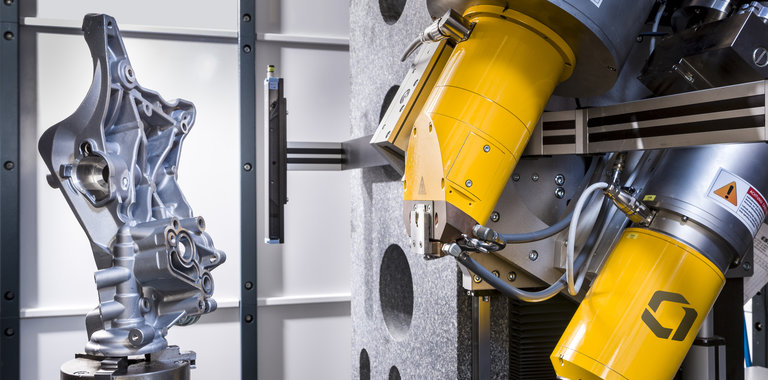

Measuring the effective focal spot

The effective focal spot is an important feature of an X-ray tube and is specified by the manufacturer. In general it can be said; “the smaller the better”. As focal spot size is also a critical exposure parameter (see section), the accuracy of the manufacturer’s information is of vital importance. Until recently, the film or pinhole method was commonly used. Since 1999, EN 12543-1 prescribes a standardized method which, however, does not have the general support of suppliers, as it requires expensive instrumentation and is time-consuming. The EN-method, suitable for effective foci <0.2 mm, involves scanning the X-ray tube radiation beam with a scintillation counter through a double collimator with an extremely small opening of 10 μm. The resulting intensity values are then represented in a three-dimensional (isometric) diagram from which the effective focal spot can be deduced. The film or pinhole method is still used by X-ray tube operators, to verify the equipment manufacturer’s data. Following the “camera obscura” principle, the X-ray tube projects its focus through a very small hole in a lead plate onto a film. The lead plate is positioned exactly halfway between focus and film. To prevent scattered radiation, sometimes the hole is made in a tungsten plug which forms part of the lead plate. After development, the effective focal spot size can be measured on the film, with the aid of a magnifying glass. The latter method, still allowed and accepted by EN, results in marginally smaller effective focal spot sizes. Establishing the effective focal spot size of a panoramic X-ray tube is considerably more complicated. It is therefore recommended to just make a radiograph of the object with the right IQIs and check the results for compliance with the quality requirements specified.