Corrosion Mapping with Two-Axis Scanner

Two-axis X-Y scanner for efficient corrosion inspections

In this article:

- Two-Axis Scanner Enhances Corrosion Mapping Accuracy: Waygate Technologies developed a two-axis X-Y scanner system to deliver consistent, high-resolution corrosion maps for industrial assets like piping and storage tanks

- Guided Workflow with Mentor UT Integration: The customizable Corrosion DM App on the Mentor UT flaw detector standardizes setup and calibration, reducing technician variability and inspection time

- Optimized for Pitting Corrosion Detection: The system uses a DM Array probe designed for detecting pitting and wall loss, with modular components for cost-effective maintenance

- Consistent Coupling and Pressure Control: The 2-axis SwitchGear Scanner ensures uniform coupling pressure during scanning, improving data reliability and repeatability

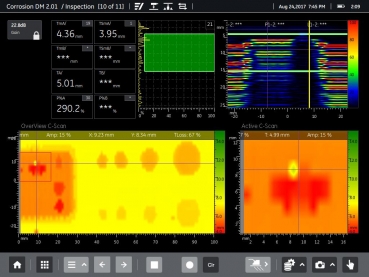

- Touchscreen Interface for Fast Data Review: Technicians can quickly interrogate suspect areas using an intuitive touchscreen interface, streamlining the inspection and reporting process

Customer Need

Industrial assets corrode and erode. Corrosion maps are an invaluable tool for locating suspect areas of corrosion as well as for comparison over time. However, currently available corrosion mapping systems are often difficult to set up consistently between operators and over time.

Application

Inspection of assets subject to internal corrosion and erosive wall loss such as piping, storage tanks, and other critical assets; requiring mapping and visual display of remaining wall thickness. Two-axis X-Y scanner for efficient corrosion inspections.

Customer Solution

By utilizing the workflow guided concept of Waygate Technologies's Mentor UT, technician set-up time can be minimized--enabling asset owners to consistently receive corrosion maps time and time again.

Product Features

- Customizable Corrosion DM App on the Mentor UT provides a guided workflow to standardize and reduce time for calibration and set-up of inspection

- Touch screen operation for fast and easy interrogation of suspect areas

- DM Array probe optimized for pitting corrosion detection - Modular probe design for cost effective replacement

- 2-axis SwitchGear Scanner for consistent coupling pressure during scanning

- Mentor UT Phased Array Flaw Detector - P/N 100N3883

- DM Acoustic Module (5 MHZ x 1.5 mm) - P/N DMARRAY_MOD1

- Probe Cable (3 m; Top Exit) - P/N DMCABLE_3M_TOP

- Two Axis Scanner - P/N MUT-SWGMAN300

- Encoder Cable (3 m) - P/N MUT-SWG-CBL3M