InspectionWorks

InspectionWorks goes beyond NDT data storage.

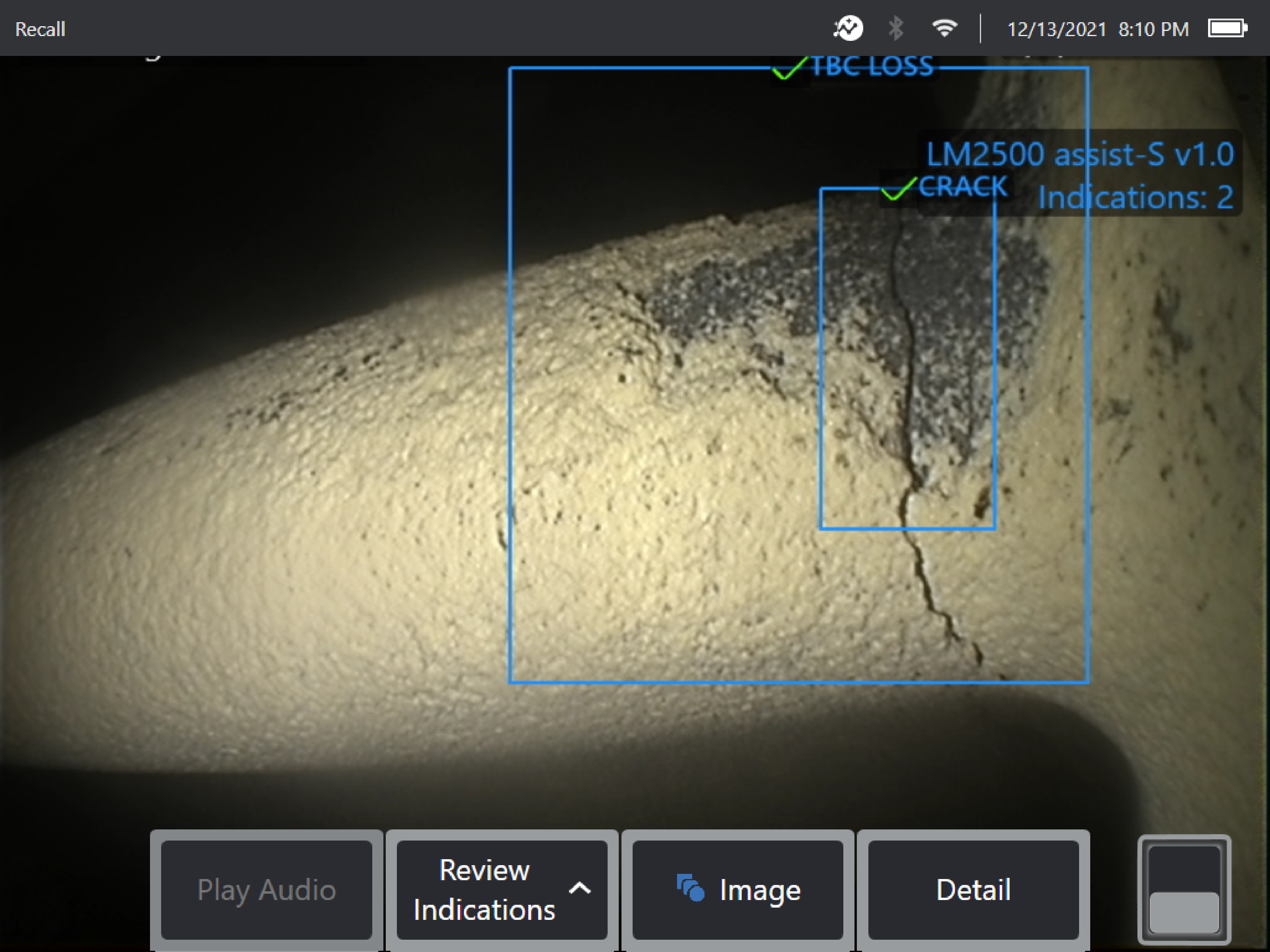

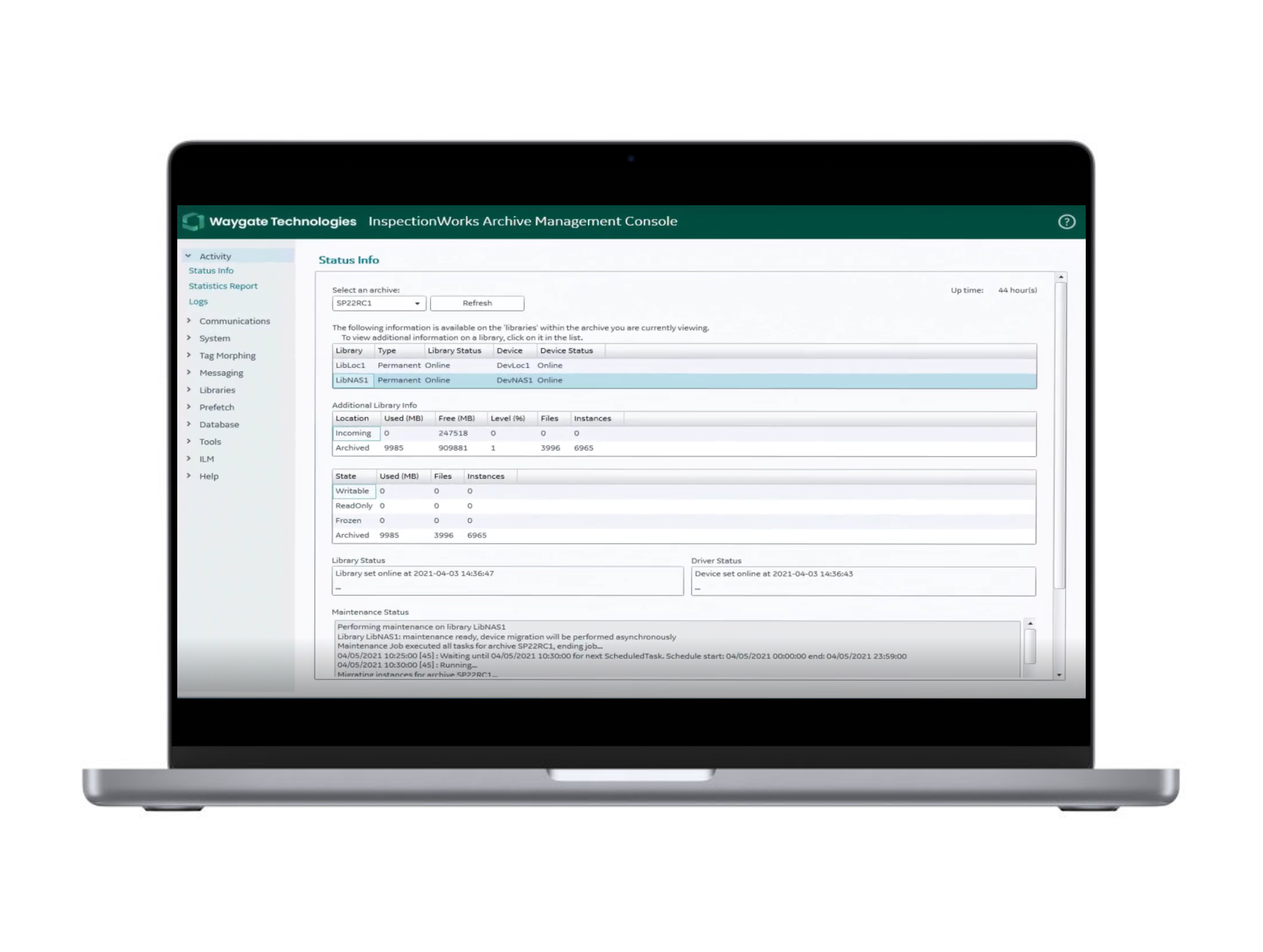

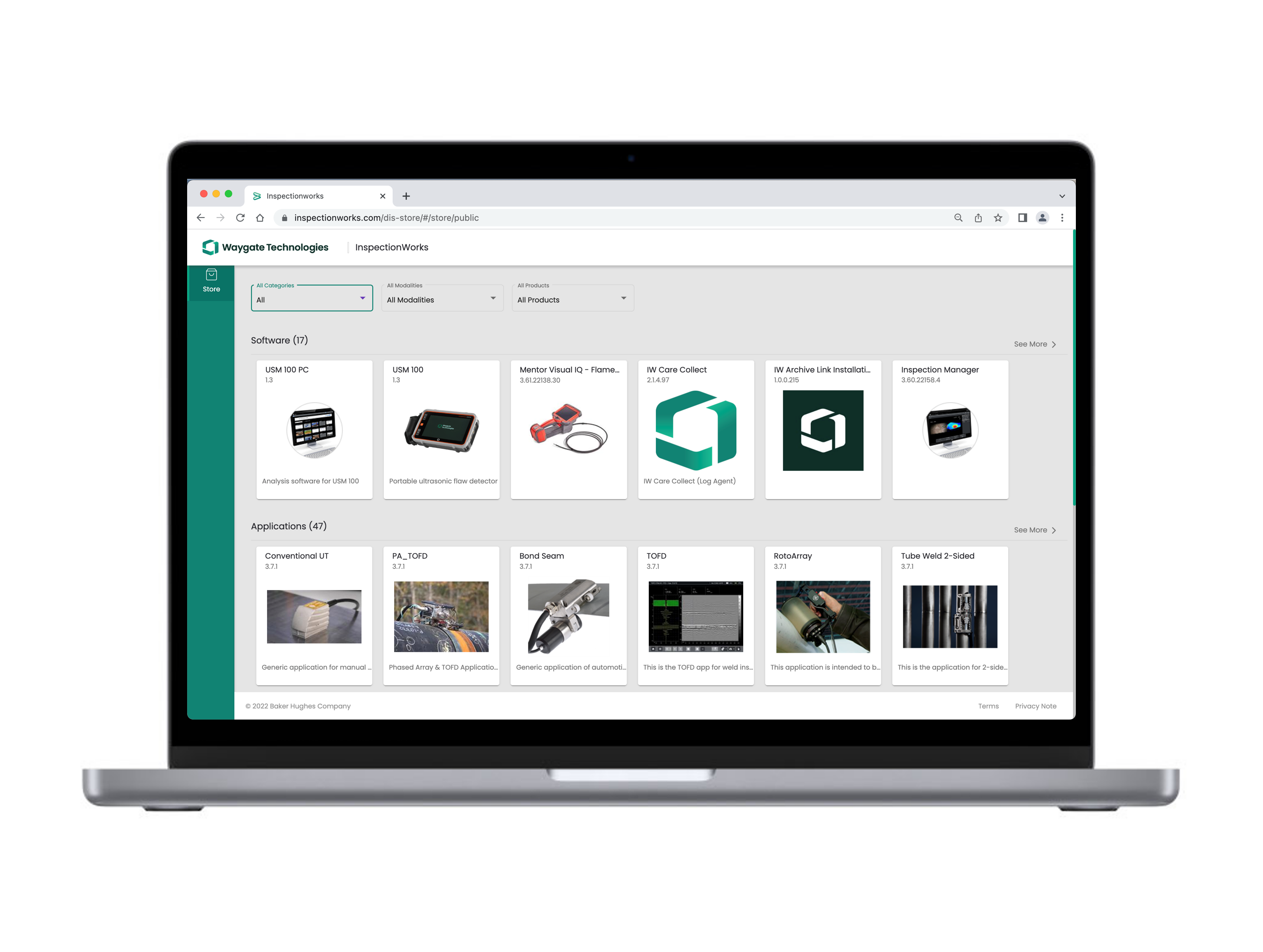

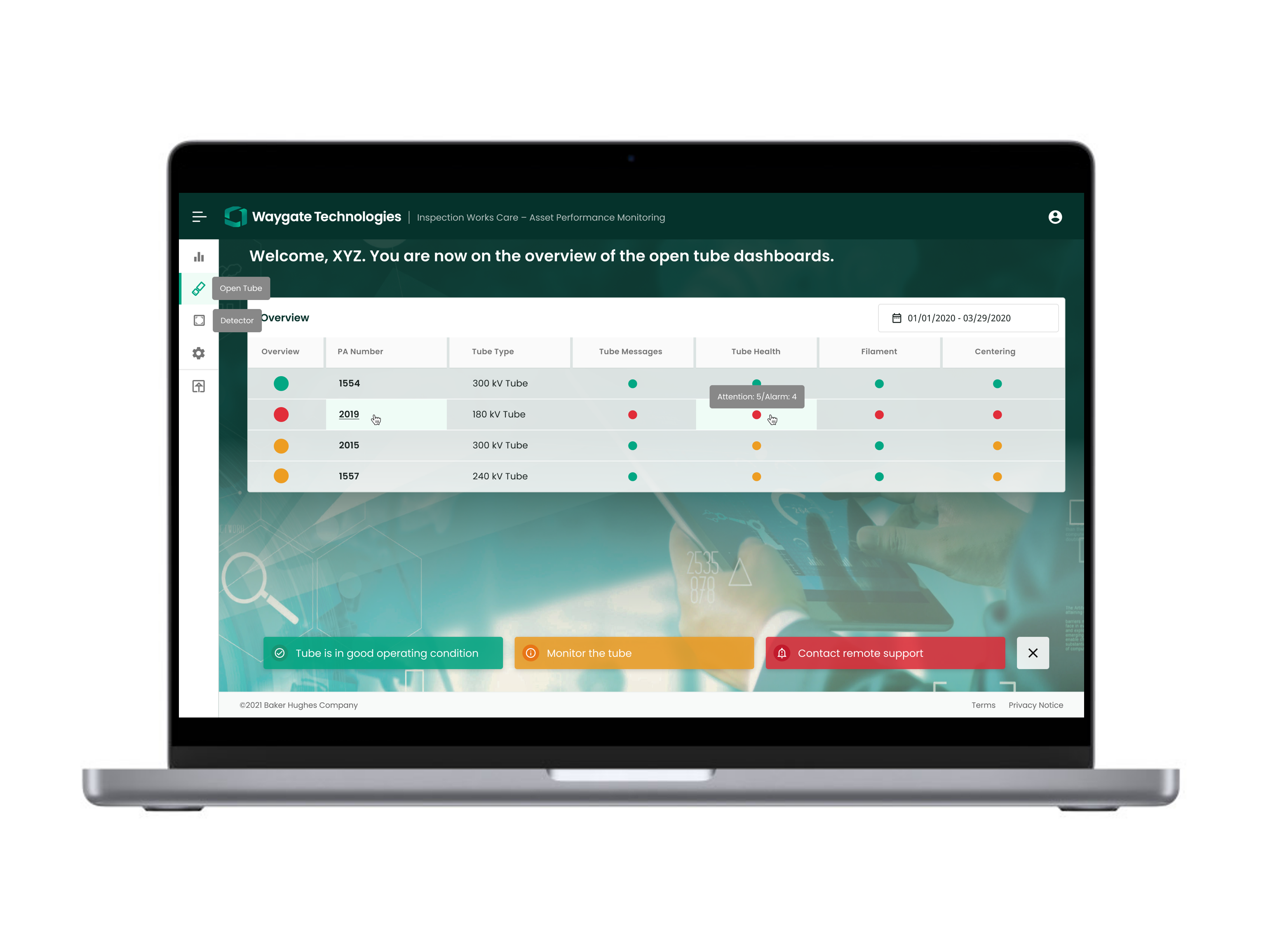

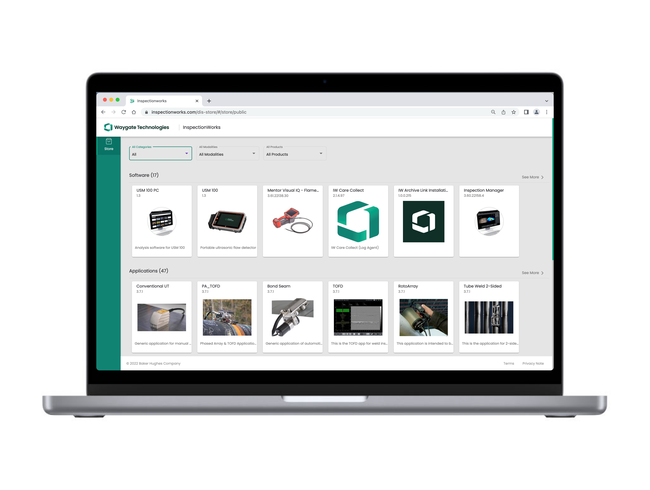

InspectionWorks is a nondestructive testing (NDT) software platform designed to simplify and standardize industrial inspections, without sacrificing quality. It streamlines inspection processes, enhances accuracy, standardizes reports, improves collaboration across key stakeholders, and much more. InspectionWorks is a complete solution that truly was built with inspectors and engineers in mind.

To set up your free account, click HERE.

Simplify your Inspection Process with InspectionWorks

Product Resources

3

Case Study

InspectionWorks Insights for the Space Exploration Industry Case Study

InspectionWorks Insights for the Space Exploration Industry Case Study

English

Case Study

InspectionWorks Insight for the Aerospace Industry Case Study English

InspectionWorks Insight for the Aerospace Industry Case Study English

English

Case Study

InspectionWorks Archive for the Aerospace Industry Case Study English

InspectionWorks Archive for the Aerospace Industry Case Study English

English