Bond Seam Inspection

Glue line and seam inspection for automotive body panels

In this article:

- Non-Destructive Testing for Adhesive Bond Integrity: Waygate Technologies developed a bond seam inspection solution to evaluate adhesive joints in automotive body panels, replacing time-consuming destructive testing methods

- Innovative Bond Seam Scanner Technology: The Bond Seam Scanner uses a flexible 10 MHz phased array probe and a spring-loaded encoder to adapt to contoured surfaces and scan bond lines up to 32 mm wide

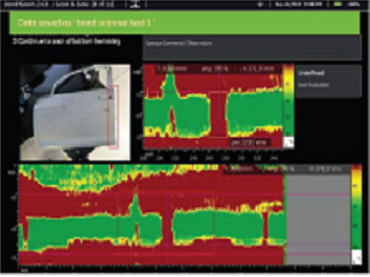

- Real-Time Visual Feedback for Quality Control: The system provides high-resolution imaging of adhesive distribution, enabling operators to detect misaligned seams or areas lacking adhesive in real time

- Streamlined Workflow with Mentor UT Integration: The Bond Scanner App on the Mentor UT flaw detector simplifies calibration and inspection setup, improving consistency and reducing inspection time

- Scalable for Automotive and Industrial Applications: Custom probe configurations and ergonomic design make the solution suitable for a wide range of adhesive bonding inspections across industries

Adhesives are increasingly being used as a joining technology for automotive body panels including edge and non-edge joints. Total accumulated length of glue lines can reach hundreds of meters per automobile body. Similar to other automotive joining processes, adhesive bonding may not provide 100% process reliability. Testing is required to identify areas with lack of adhesive as well as misaligned bond lines. Traditionally, this has been accompished only through time-consuming and costly destructive testing.

Glue line and seam inspection for automotive body panels

BHGE Inspection Technologies provides a non-destructive method for conducting bond seam inspections. The Bond Seam Scanner is easily clamped on body panels joined by a seam or other adhesive bonding process. The design enables the array to adopt to contoured parts commonly used in automobile designs. A spring-loaded encoder wheel provides a stable inspection platform and tracks the sensor position for bond lines up to 32 mm wide. A protection foil minimizes the need for couplant and facilitates manual scanning. The innovative Bond Seam Scanner linear array design ensures inspection spatial resolution and detection resulting in an easily interpreted visual image of the presence of adhesive allowing the operator to evaluate the overall width of his bond seam and identify where adhesive requirements are not met. Custom array probes can be developed to inspect similar adhesive applications in automotive and other industrial segments.

Product Features

• Bond Scanner App on the Mentor UT provides a guided workflow to standardize and reduce time for calibration and set-up of inspection

• Touch screen operation for fast and easy interrogation of suspect areas

• Flexible 10 MHz array to contour to body panel curvature

• Spring loaded and sealed encoder for optimal positioning

• Protective foil for reduced wear and couplant

• Ergonomic handling and a smooth scanning operation

• Silicone oil free

• Mentor UT Phased Array Flaw Detector - P/N 100N3883

• Probe, LA10-32 flex (BondScanner) - P/N 0600325 (includes frame, clamp, encoder)

• Bond Scanner Foil - P/N 0600199