Shana Telesz: Potential of the new Phoenix Power|scan HE

In this article:

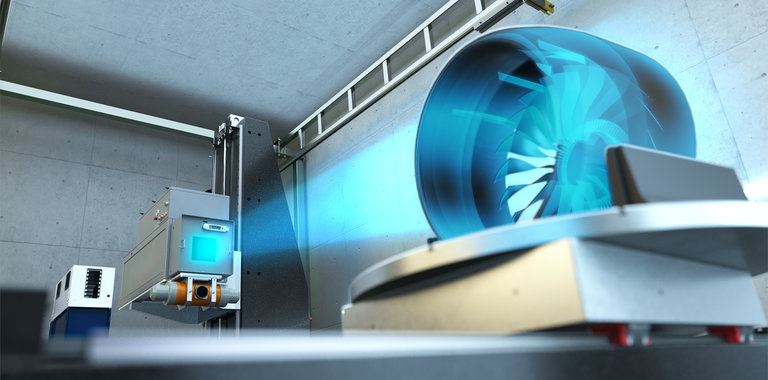

- Phoenix Power|scan HE Unlocks High-Energy CT for Industry: Waygate Technologies introduces the Phoenix Power|scan HE, a high-energy computed tomography (CT) system designed to inspect large, dense, and complex components with unprecedented precision

- Targeting Advanced Manufacturing Sectors: The system is tailored for industries like aerospace, automotive, and additive manufacturing, where intricate designs and dense materials demand deep-penetration imaging

- Solving Accessibility and Scalability Challenges: Unlike custom-built or limited-access high-energy CT systems, Power|scan HE offers a commercially viable, scalable solution for broader industrial use

- Enabling Innovation in Product Design: By providing detailed internal imaging of components like electric motors and jet engines, the system supports faster development cycles and higher-quality manufacturing

- Expert Insight from Shana Telesz: Industrial Radiography Technology Expert Shana Telesz shares how the system was developed to meet growing demands for inspection capabilities in next-generation manufacturing

As Industrial Radiography Technology Expert Shana Telesz has been supervising the development of Phoenix Power|scan HE since day one. Before that, she spent several years in product management and mainly worked with clients from the aviation and space, automotive, batteries and a few other industries. In this interview Shana explains which potential Waygate Technologies saw in the new technology and how it was developed.

Question: Looking at the state of industrial CT, can you give us a broader overview of the capabilities that are out there and for which reasons?

Shana Telesz: Industrial CT or industrial radiography technology in general is used to an ever-increasing extent: By now, the traditional use in a quality control and failure assessment function is a standard and for many of our customers just the beginning. Companies use it to optimize production processes, for metrology tasks and it’s very common that research and development of new products is heavily aided by industrial CT.

That being said, we realized in our daily work with clients from around the world and across multiple industries that at the top end of capabilities, options for industrial inspection can be limited. The technology to scan very large, dense and complex parts with deep penetration might be out there but it’s not really commercialized: You either have to construct your own individual – and of course very expensive – solution or you would have to calculate with a lot of time to get a slot in one of the very few scanners out there. For an increasing number of companies that want to transform their manufacturing standards or bring new categories of products to the market, this situation is not optimal. We wanted to change this and make high energy CT available to those companies. Power|scan HE is the result of this.

Question: What industries are you mainly targeting with the new product?

Shana Telesz: As I just mentioned, the number of use cases for Power|scan HE is increasing constantly. At this point in time, we believe that the system is most interesting for industries such as aviation, space and automotive. But everywhere where manufacturing complexity is high or rising to reach new levels, Power|scan HE can enable leaps in product design. As such, we see it also for example in additive manufacturing where it can help to create ever more complex and intricate structures. When we take a look at transportation, it gives us the ability to inspect entire electric car motors in one part, saving time and money. The same goes for example for jet engines or large components that comprise modern turbines. It really opens up new possibilities that until now were reserved only to a small user base.

Question: So Power|scan HE is Waygate Technologies’ high-energy CT solution for the inspection of large parts or of those that are difficult to penetrate due to their material properties: Can you give us a rundown of the system’s main characteristics?

Shana Telesz: Power|scan HE is housed in a bunker which weighs almost 1,200 metric tons and uses a 9 MeV linear acceleration CT scanner. Due to its power and our own technologies such as Scatter|correct we are able to produce very clear and precise images of complex parts and assemblies – in a recent scan for example, we were able to capture loose powder particles of smallest size within a heat exchanger module which was produced in additive manufacturing.

Inspected parts can weigh up to 1,000 kg and be as large as two meters in diameter. In terms of penetration of materials, Power|scan HE is about 20 times as powerful as our next largest system V|tome|x L and is able to penetrate down to 15 to 17 centimeters of steel.

Question: Please tell us more about the development and maybe also the challenges you encountered along the way.

Shana Telesz: When you develop such a powerful system, control over this enormous amount of energy is key – Power|scan HE is basically built around a 9 MeV linear acceleration CT scanner, which generates an incredibly high amount of energy. Even with more than 125 years of experience in commercial x-ray this is no easy task.

Our main challenge was to figure out how to deal with this power and it guided most of the development process. Finding answers to this question of ‘power containment’ required efforts within our team but of course also with our suppliers and partners which also did not previously work on such a large installation. It took quite a lot of pioneering work but ultimately, we succeeded.

When we look beyond the actual system development, the COVID pandemic posed a major challenge. Waygate Technologies is a global organization with teams situated in many countries. In this case, most of the design work was done in Wunstorf, Germany, while construction took place in Cincinnati in the US. In normal times this would have meant many miles flown and visits back and forth between the teams involved. Switching most of this to virtual meetings and limiting travel to only an absolute minimum required us to always remain flexible and be open to new ways of working together.

In the end, development and construction of Power|scan HE took about three years. While not as fast as originally planned, I believe that given the COVID-induced delays, this is still something that the team can be proud of.

Question: Assuming I am a potential user, what would be the next step for me? How can I make use of Power|scan HE and how long do I have to wait to have my parts scanned?

Shana Telesz: We are happy that one third of the capacity of our Cincinnati site is booked even before we even started marketing the new product. It shows that we are on a good track and that there really is a market. Prospective customers should get in touch with their local Waygate Technologies representative to assess what exactly they require and receive a quote. We of course also offer demonstrations of the system in our Customer Solutions Center in Cincinnati. After that it is really a matter of aligning with our application engineers and experts on site to get the inspection quality that is required for the individual task.

As things stand right now, the turnaround from the first contact with our sales team until the inspection can take place is just a few weeks but we expect this to become longer as interest in Power|scan HE becomes better known among industry experts. So my advice would be to get in touch rather sooner than later – which also applies if you are looking to construct your own Power|scan bunker which is of course also an option!