Rely on faster, more precise AXI inspections for even the smallest components

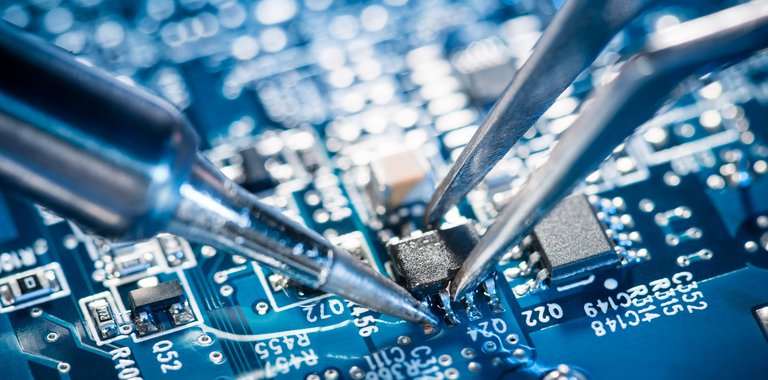

Microscopic electrical components are the hidden heroes in millions of different devices across a wide spectrum of industries. Though small, these components play an important role in the healthy functionality of everything from airplanes to smartphones. Ensuring the integrity of electrical components via industrial x-ray electronics inspection is vitally important not only for maintaining brand reputation – but also for public reliability and safety.

Waygate Technologies' family of high-performance industrial x-ray inspection machines and intuitive software tools introduce a new industry standard for efficient, reliable, and non-destructive testing (NDT) live inspections. Extreme high positioning accuracy make our systems an effective and reliable solution for a wide spectrum of 2D and 3D offline inspection tasks: R&D, failure analysis, process, and quality control.

As safety standards become more stringent while assembly complexity increases, precise X-ray inspections of microscopic electrical components during manufacturing and assembly in products like cables, switches, and circuit boards are more important than ever.

Automated X-ray inspection (AXI) is ideal for:

- Electronics inspection

- Solder inspection

- Printed Circuit Board Assembly (PCBA) inspection

- Printed Circuit Board (PCB) inspection

- Battery inspection

- Ball Grid Array (BGA) inspection

- Through Hole Technology (THT) inspection

Our radiographic testing and industrial CT equipment

The Phoenix Microme|x Neo and Nanome|x Neo provide high-resolution 2D X-ray technology, Planar|CT and 3D computed tomography (CT) scanning in one system. They are ideally suited for industrial X-ray electronics inspections in process and quality control for greater productivity, failure analysis, quality of your products, and R&D.

The Phoenix V|tome|x M is Waygate Technologies most versatile and precise X-ray microfocus CT cabinet system for 3D metrology and analysis. This highly productive Dual|tube scanner with its 300 kV microfocus and optional 180 kV nanofocus X-ray tubes delivers improved accuracy at unprecedented speed.

The Phoenix V|tome|x M Neo is a next-generation industrial CT system, building on the success of the widely-used Phoenix V|tome|x platform with over a thousand installations worldwide. It offers remarkable advancements, including improved image results, an expanded scanning area for larger and heavier samples, variable focus detector distance, and a new cabinet design for enhanced flexibility and accessibility.

The Phoenix V|tome|x C is a high performance compact industrial 450 kV Minifocus CT system for inspection and 3D metrology of a wide applications range such as large light metal castings, turbine blades, AM parts etc. The V|tome|x C450 is also available with Mesofocus tube for more resolution.

The combination of penetration power and our advanced CT features such as Scatter|correct technology make this CT system predestined to scan extremely large, heavy and high absorbing complex parts and assemblies with unmatched speed, precision, and ease of use — enabling faster, more precise inspections.