TRIC

Wireless highly mobile remote controlled robot

In this article:

- TRIC: A Breakthrough in Robotic Inspection: The Three-Wheel Inspection Crawler (TRIC) is a highly mobile, wireless robot developed under the EU Horizon 2020 AEROARMS project to perform remote inspections in industrial environments

- Enhanced Safety and Cost Efficiency: TRIC reduces the need for human entry into hazardous areas, significantly lowering environmental, health, and safety (EHS) risks and cutting inspection preparation costs, which can account for over 90% of total inspection expenses

- Versatile Sensor Integration: The robot supports various inspection technologies—including ultrasonic testing (UT), eddy current (EC), and visual sensors—making it adaptable for diverse industrial applications

- Advanced Mobility and Autonomy: Equipped with magnetic wheels that steer and tilt, TRIC navigates complex surfaces like pipes and domes. It also features autonomous navigation capabilities and drone transport potential for hard-to-reach areas

- Reliable Wireless Operation: TRIC operates independently for over an hour and transmits high-bandwidth inspection data and control signals wirelessly up to 150 meters, ensuring flexibility and real-time monitoring

Industrial assets in oil & gas, power and other industries have to be inspected on a regular basis. While in recent years aerial inspection is more and more applied to get on overview of the plants situation, contact inspection methods, such as ultrasound (UT) or eddy current (EC) are still mandatory to reliably assess condition and safety of the critical components in the plants. The task preparation and the EHS (environmental, health and safety) part of such a contact inspection can make up for 90% or more of the overall cost. If these inspections could be performed remotely, i.e. the operator does not have to work in a dangerous situation, large cost savings could be achieved, even if the robotics system is slower than the human operator.

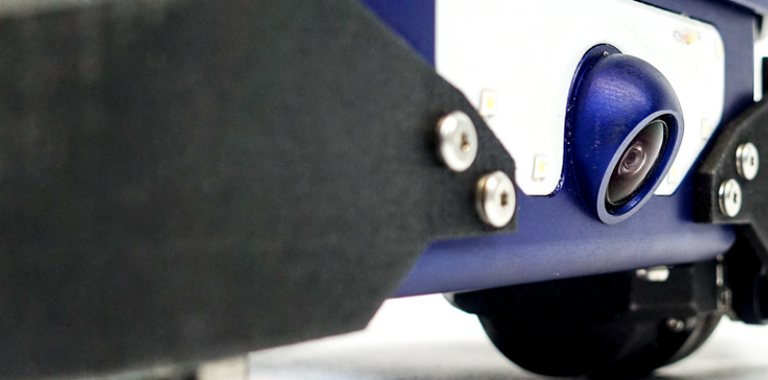

Within the EU H2020 (Horizon 2020) project AEROARMS, GE Inspection Robotics (GEIR) has developed the TRIC (Three Wheel Inspection Crawler). The intention was to provide a highly mobile remote-controlled robot that carries the inspection sensor of choice, e.g. UT, EC or visual sensors. The robot reaches the remote area of interest either by maneuvering from an easy to access deployment location or by transport by a drone. Once at the target, location the robot performs its inspection task automatically, a user assisted or remote controlled.

See it in Action

The high mobility, that allows the TRIC to move flexibly along the structures to be inspected (tubes, elbows, vessels, structural components, …), is provided by three special magnetic wheel drives. Each wheel can be steered actively and can tilt to conform with curved surfaces (tubes, elbows, vessels, domes). Three cameras provide navigation support as well as the capability for quick visual checks. The on-board batteries enable the robot to run independently from a power source for more than 1h, depending on the inspection task and the local geometry. Separate wireless links transmit the inspection data (high bandwidth) as well as the robot control data (high priority) to the base station that can be as far 150m away. In the center of the robot, a sensor bay provides sufficient space to mount the sensor system of interest.

Two TRIC’s with protection rating IP64 have been built and used extensively for tests on industrial structures. The next step in the AEROARMS project, the transport of the TRIC to and from the remote location by a drone will be tested in 2018. The autonomous navigation capabilities of the robot on the structures will be continuously increased until then.

Find out how our products and services can help in your business. Reach out to our sales representatives or ask questions to the technical experts.