Image

Image

Eyebrow

Blog

New release of Phoenix Nanome|x and microme|x Neo

2 min read

In this article:

- Next-Gen X-ray and CT for Electronics Inspection: Waygate Technologies launched the updated Phoenix Nanomex and Micromex Neo systems, setting a new standard in microfocus and nanofocus X-ray and computed tomography (CT) for electronics quality assurance

- Enhanced Imaging with Ultra-High-Resolution Detectors: The systems offer detector options with pixel sizes as small as 85 µm, enabling precise inspection of small components like semiconductors and PCBs

- Smart X-ray Tube for Component Protection: A redesigned X-ray tube with dose control minimizes radiation exposure to sensitive electronics, preserving component integrity during inspection

- Streamlined Workflow with Automation and MES Integration: Features like automatic inspection reports, CAD file import, and Manufacturing Execution System (MES) connectivity improve efficiency and traceability

- Ideal for R&D, Quality Control, and Failure Analysis: The systems support a wide range of applications across electronics manufacturing, from process optimization to defect detection and product development

Earlier this year, Waygate Technologies launched a new release of our Phoenix Nanome|x and Microme|x Neo product, introducing the latest industry standard for microfocus and Nanofocus X-ray and CT—including Planar CT--inspection capability with a focus on electronics inspection applications. The new release provides:

- More detector options to better suit multiple applications

- An optimized X-ray tube to protect X-ray-sensitive components

- Enhanced software features for increased efficiency and ease of use

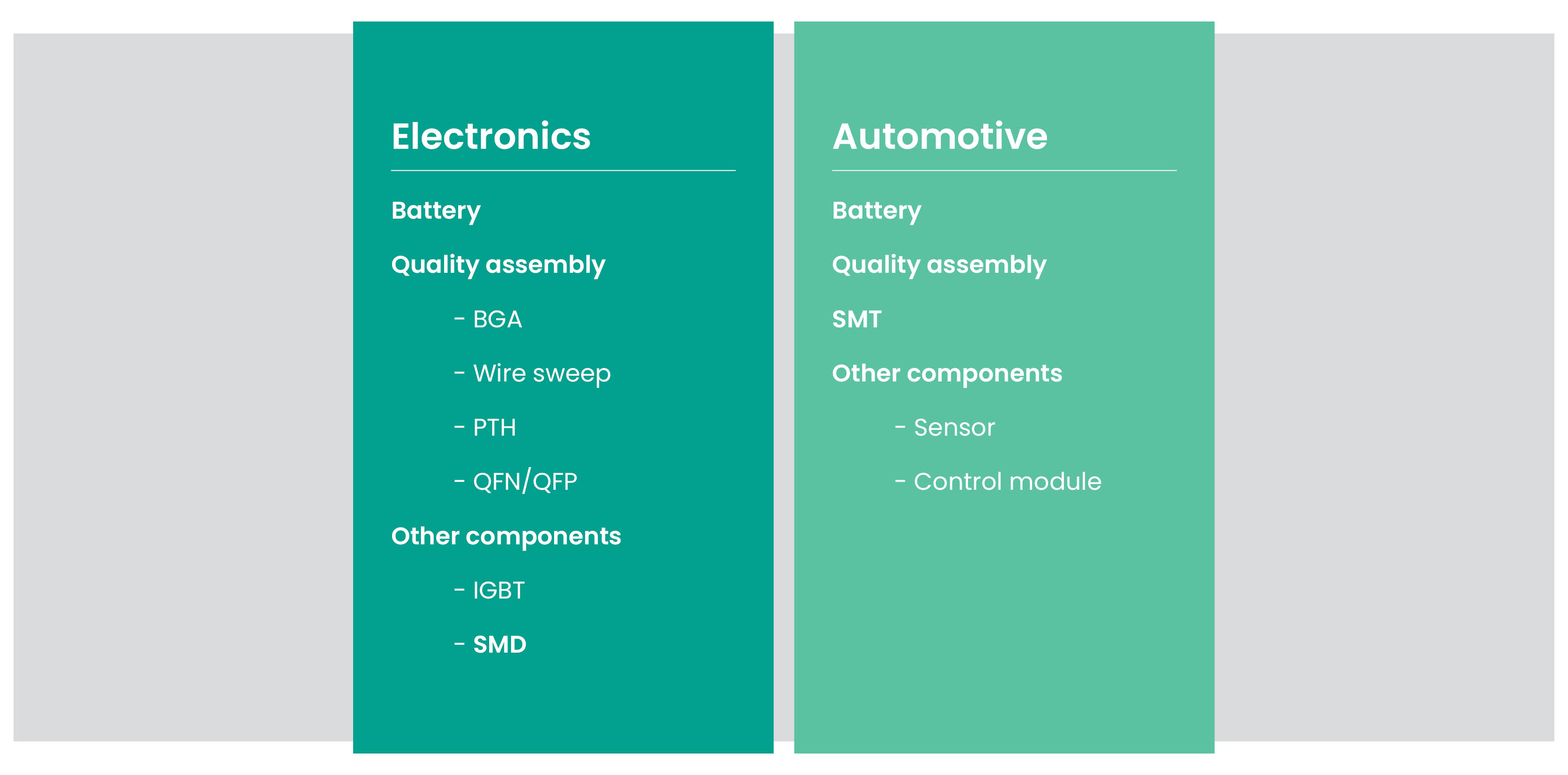

Applications: The updated product offers a broad array of applications across two key industry verticals displayed above.

Key features and benefits:

- Ultra-high-resolution detector option with 100/85μm pixel size for small sized components and semiconductors

- Smart X-ray tube and dose measurement protects (inspected) components from prolonged X-ray radiation

- Automatic inspection reports are generated for enhanced efficiency and ease of use

- Manufacturing Execution System (MES) interface and CAD file import option increase system interconnectivity

Waygate Technologies

As the global leader in non-destructive testing (NDT), we obsess over the little things, so you don't have to. We ensure safety, quality and productivity for major industries around the world.