ROBINS

Filling the technology and regulatory gaps that today still represent a barrier to the adoption of Robotics and Autonomous Systems

In this article:

- ROBINS Project Enhances Ship Inspection with Robotics: The ROBINS (ROBotics technology for INspection of Ships) initiative, co-funded by the EU Horizon 2020 program, aims to overcome technological and regulatory barriers in robotic ship inspections

- Advanced Robotic Platforms for Confined Spaces: The project develops aerial and crawler-based robotic systems capable of navigating complex ship environments like ballast tanks and remote compartments

- Sensor-Driven Navigation and Control: ROBINS integrates multiple sensor types—including odometry, gyros, cameras, and edge detection—to enable precise, semi-autonomous navigation and inspection

- Innovative Probe Handling for Remote UT: A new articulated probe handling tool allows ultrasonic testing (UT) probes to access hard-to-reach areas, such as welds and corners, improving inspection coverage and flexibility

- Unified Virtual Inspection Environment: The system combines real-time data acquisition with image-processing algorithms to create a virtual inspection interface, streamlining analysis and reporting for ship maintenance teams

ROBINS (ROBotics technology for INspection of Ships) is a collaborative project co-funded by the Research DG of the European Commission within the activities of the Horizon 2020 EU Research and Innovation program. The ROBINS project aims at filling the technology and regulatory gaps that today still represent a barrier to the adoption of Robotics and Autonomous Systems (RAS) in activities related to inspection of ships, understanding end user’s actual needs and expectations and analyzing how existing or near-future technology can meet them.

Aerial Platforms

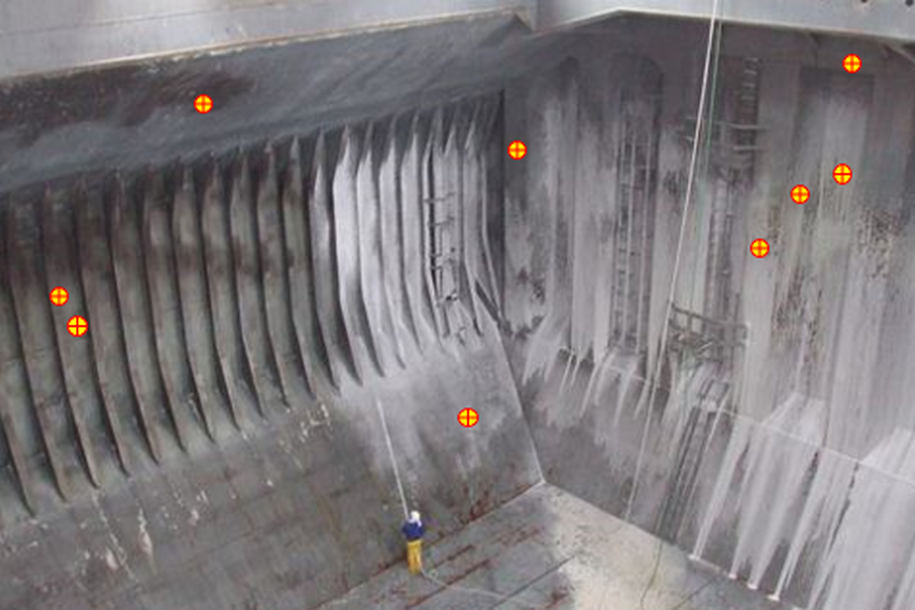

Aerial platforms for highly autonomous unsupervised navigation, able to explore efficiently wide spaces and flying platforms to be employed in highly “irregular” confined spaces like ship ballast tanks.

Robotic Crawlers

Crucial for a commercially attractive robotic inspection of ships is the ability to reach remote, not directly accessible location, be it due to height or in confined spaces. ROBINS shall develop control strategies based on multiple sensor inputs to support the operator.

Data Processing

Integrating image-processing algorithms specifically developed for the recognition of ship hull’s critical or suspect areas in the software dedicated to virtual tours, thus creating a unified environment for virtual inspection.

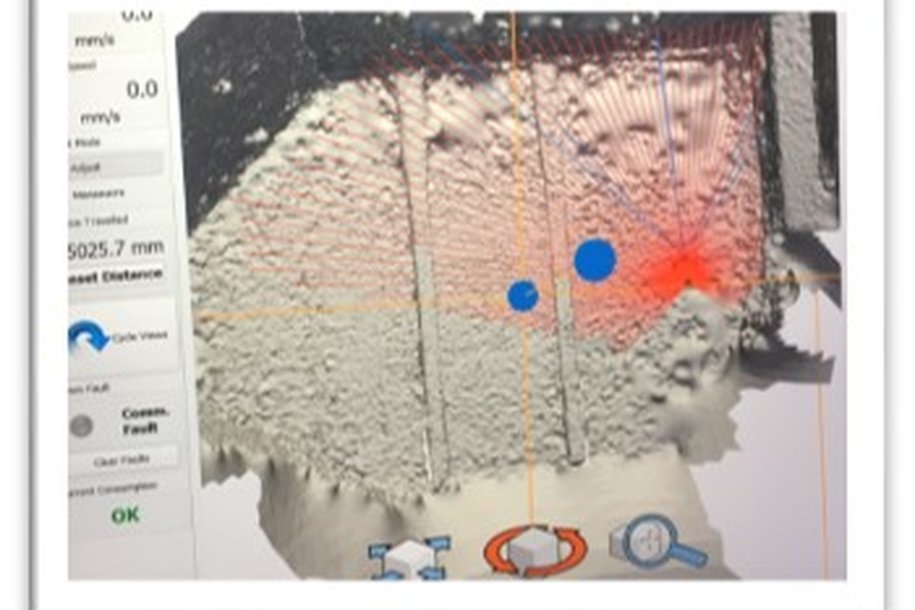

For efficient operation and user acceptance the simplicity of handling and navigation of the inspection tool cannot be underestimated. ROBINS shall develop control strategies based on multiple sensor inputs to support the operator in reaching his/her inspection target quickly. The operator shall be able to concentrate fully on the very inspection task and must not be deviated by complicated steering a complex robot. We will address this gap using multiple sensors and appropriate control strategies. This can involve: odometry (1), inclination sensors and gyros (2), cameras (3) edge detection (4), distance sensors (5) and information from outside such as from the flying platform (6) or a fixed base station (7).

For remote UT inspection, the UT probe has to be brought to the inspection location by a manipulator and then be put in close contact w/ the test object. This is solved for access path free of obstacles by sliding the probe on the surface or simple lifters from the launching point to the inspection position. However, such standard probe systems prevent passing obstacles – such as 90° corners – along the access path. Additionally, they are not flexible enough to position the probe at some critical locations, such as welds. In ROBINS, an articulated probe handling tool shall be developed and integrated to both position the probes flexibly as well as to move it out of collision situations.

In remote inspection, the probe is far away from the operator controlling the data acquisition. The data quality (electrical noise) and the need to feed couplant liquid to the probe contact limits this distance or impairs signal quality. We shall develop or adapt and then integrate a miniaturized UT control system and couplant feed system has to be integrated on-board the robot.

- 3D Localization of the crawler inside the cargo hold

- Taking Ultrasonic Thickness reading at points of interest

- Local Planning and Auto Pilot mode

- Cloud Reporting

- Collaboration with drones

Find out how our products and services can help in your business. Reach out to our sales representatives or ask questions to the technical experts.