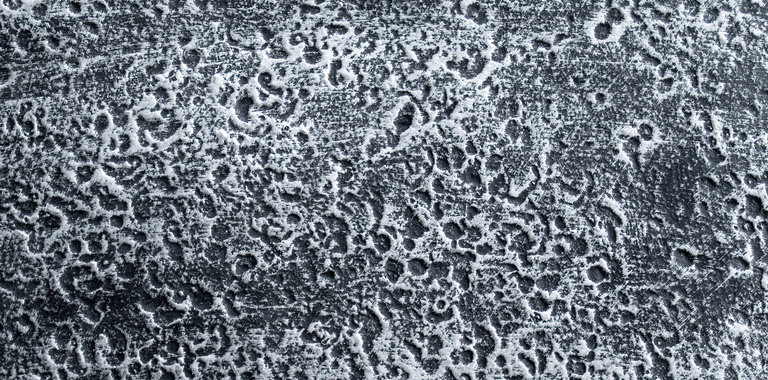

Steel plates are the base material further processed into pipes, wind generator towers, ship hulls and a variety of other finished goods. Ensuring this base material is defect free before further processing reduces overall cost and helps eliminate end item failure.

The Krautkrämer line of automated, in-line ultrasonic plate testers span applications from steel used in SAW Pipe to heavy plates used in wind towers and other demanding structural applications. The Krautkrämer line of steel plate testers are complete turnkey systems ready to integrate into customer production lines or as standalone systems. These machines provide 100% full-body inspection or sampling inspection that match the throughput of production lines.

We used to be GE Inspection Technologies, now we’re Waygate Technologies, a global leader in NDT solutions with more than 125 years of experience in ensuring quality, safety and productivity.

- Configurations available for plates 1.5 m – 5 m (4.92 - 16.40 ft.) in width and 6 mm – 100 mm (.24 - 3.94 in.) in thickness

- Material handling solutions available for plates up to 55 m (180 ft.) in length

- Probe arrays available for top or bottom surface testing

- Optional edge, head and tail inspection capability

- Probe holders with hardened steel slides ensuring long life and ultrasonic probe protection

- Ultrasonic probes provided in separate Transmitter and Receiver crystals to ensure proper part inspection

- Variable linear throughput speeds up to 1000mm/s (39.4 inches/s)

- Report generator stating the condition of every plate evaluated according to the chosen standard

- Meets final test requirements for plates used in critical infrastructure applications

- Easy interpretation of inspection results via Automatic Evaluation software

- High throughput capable of matching upstream and downstream cycle times

- Parallel Flaw testing and plate thickness mapping

Get in touch with one of our Waygate Technologies subject matter experts.